Engineer

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MorePlant Software Enhances Real-Time Condition Monitoring

NPE2024: MiVue, a division of the ACS Group, is showcasing expanded capabilities for its plant monitoring software for plastics processors.

Read MoreERP Empowers Mold Builder to Increase Speed, Efficiency, Accuracy

Highly integrated but easy-to-use ERP system helps Delta Mold Inc. increase unattended hours, uptime, productive labor hours and improve mold delivery times.

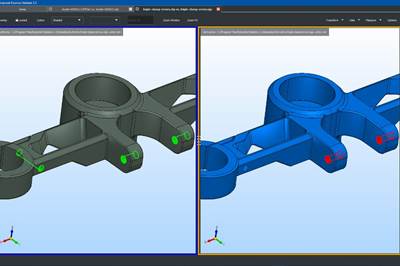

Read MoreValidation Software Enables Efficient Translation of CAD/CAM Data

Verisurf CAD/CAM, now providing access to Kubotek Kosmos Validate software, is designed to ensure data integrity and enable users to perform metrology workflows in a seamless CAD environment.

Read MoreProduction Tracking Software Enables Smart Factory Functionalities

NPE2024: Wintriss is demonstrating the advanced features behind its ShopFloorConnect software and ShopFloorTracker hardware, key to capturing, tracking and managing data collection.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

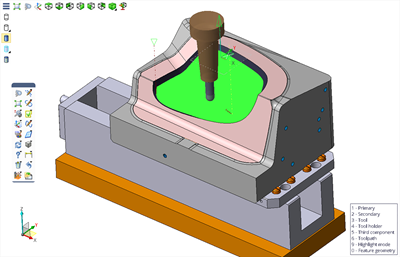

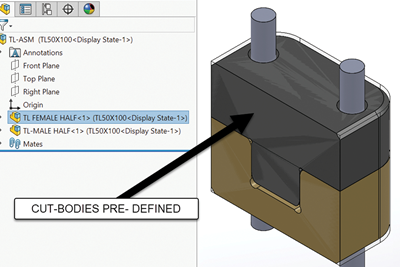

Read MoreHow to Customize an Interoperable Software Solution for Your Moldmaking Process

A connected software solution streamlines the moldmaking process by providing a unified source of design data, enhancing efficiency and reducing errors, with five key steps benefiting from this integration.

Read MoreVIDEO: Standardization and the Future of Moldmaking

Progressive Components President Glenn Starkey discusses their focus on standardization and the future of moldmaking (it’s here to stay!).

WatchSoftware Aids Localization of Injection Mold Inventory

NPE2024: Hasco introduces Mould Track for the precise tracking of injection mold inventory for improved production planning.

Read More