Mold Business Index: Underlying Data Show Strong Index Components

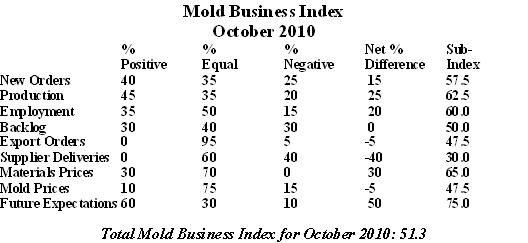

The total Mold Business Index is a weighted average of the Sub-Indices for new orders, production, employees, backlog, exports, and supplier deliveries. The Mold Business Index (MBI) for October 2010 is 51.3.

The Mold Business Index (MBI) for October 2010 is 51.3. This is a 1.5-point decrease from the September value of 52.8, but it is a 5.5-point increase from the MBI value of 45.8 posted in October of last year. The underlying data indicate that the past few weeks have actually been stronger than our headline number of 51.3 suggests. Both the New Orders and Production components are robust this month. The main drag on the overall MBI value in October is the unusually low reading for Supplier Delivery Times. This month’s MBI data remain consistent with the rise in U.S. spending for capital equipment that has highlighted the first three quarters of 2010. The Future Expectations sub-index indicates that moldmakers’ attitudes about future business levels are optimistic. Mold Prices appear to have stabilized, but Materials Prices (especially for steel and resins) continue to rise.

The U.S. economy continues to expand at a sluggish rate. Real GDP is growing right at 2% per year compared with its estimated, long-term potential of about 3%. Only about 75,000 jobs are being added a month on average, which is half the pace needed to maintain a stable unemployment rate. We expect the unemployment rate to remain at or near its current level for another two to three quarters. Foreign trade and business investment in new equipment will be bright spots in the economy in the coming months.

Our forecast for GDP growth in 2011 has been lowered modestly to 3%, but the much better outlook for 2012 and 2013 remains unchanged. In the current politically-charged and fragile economic environment, it is difficult to recognize that the underlying issues that caused the Great Recession (and that still weigh on the recovery) are slowly, but steadily being resolved. Households and businesses are rapidly paying down debt, big corporations have slashed costs and are very profitable, and the overbuilding that occurred in the boom is slowly getting absorbed. Getting through the next 12 months will be difficult, but by this time next year the improved fundamentals will become evident.

The New Orders component for our MBI indicates that the overall number of new projects increased in recent weeks, as this sub-index for October is 57.5. Production activity stayed quite strong, as the latest Production sub-index is 62.5. The Employment component is 60.0 indicating that there was another encouraging rise in payrolls last month. The Backlog component is 50.0 for October which indicates that backlogs were stable even as production levels increased.

The Mold Prices sub-index for October is 47.5, and a few survey respondents continue to report pressure from customers to lower the prices of new molds. The prices paid for materials, primarily steel, continue to escalate. The sub-index for Materials Prices is 65.0. Supplier Delivery Times were noticeably slower, as this sub-index plunged to a value of 30.0. There was little change in offshore orders for new molds, as the Export Orders sub-index is 47.5.

The most-cited problem confronting North American moldmakers in recent weeks is uncertainty about the U.S. economic recovery. Other problems receiving multiple mentions include: pressures from customers for lower prices and shorter lead-times; offshore competition, especially from China; a skilled labor shortage; and getting paid in a timely manner.

Our Injection Molding Business Index (a measure of production levels for injection molders) posted another solid increase in the third quarter of 2010 when compared with the previous year. This Index has registered growth throughout 2010, and the latest forecast calls for a gain of 7% this year. Consistent gains in the Mold Business Index depend on sustained growth of 4% to 5% in the output of injection molded products. The trend in the moldmaking industry lags the trend in the processing sector by about six months.

The Mold Business Index is based on a monthly survey of North American mold makers. Mountaintop Economics & Research, Inc. conducts the survey, and then calculates a diffusion index based on 50.0. A value above 50.0 for the MBI indicates that business activity expanded in the previous month, while a value below 50.0 means that business levels declined.

Related Content

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreMMT Chats: Marketing’s Impact on Mold Manufacturing

Kelly Kasner, Director of Sales and Marketing for Michiana Global Mold (MGM) talks about the benefits her marketing and advertising, MGM’s China partnership and the next-generation skills gap. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreTransforming Moldmaking into Digital Industrial Manufacturing

Moldmaking and digitalization is at the core of this global industrial manufacturing company’s consolidation and diversification plan.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More