MMT's August IMTS Digital Edition Is Available

This month, along with an IMTS Exhibitor Product Showcase, we take a look at a variety of cutting tool, machining, inspection and measurement, advanced manufacturing and workforce development challenges and solutions.

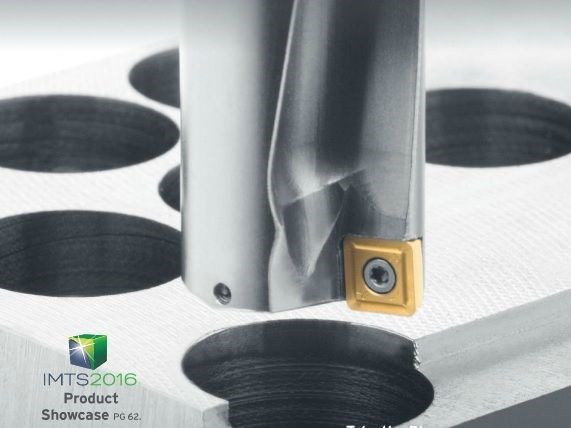

MoldMaking Technology's August IMTS digital edition is now ready for you to view. This month we take a look at strategic operation planning and cutting tool system optimization that can make plunge roughing a productive, stable choice for high-volume material removal; review a strategy that ensures each component in the inspection value chain works together, keeping the digital thread intact from design to quality reporting; break down how a new venting valve can help overcome standard mold venting limitations and improve mold performance; explain that lightweight plastic parts production with high surface quality takes the right blend of mold technology and molding process; and, highlight an IMTS-featured mold builder, South Coast Mold, and how it combines its knowledge and technology to optimize machining capabilities.

The issue also examines two training/education and workforce development issues. One involves project-based learning and the other is part one of defining the skills gap problem.

This month also includes our IMTS Exhibitor Product showcase to give you an inside look at some of the innovation coming to Chicago next month.

Related Content

-

Exploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

-

MMT Chats: Acquisition Trends and Lessons for Mold Builders

Jim Berklas is a former full-time M&A lawyer for several of the largest private equity firms in the country and has 25 years of M&A experience and 200 closed transaction. Today, he is founder and M&A Leader with Augmented Industry Services. He joins me for this MMT Chat on mergers and acquisitions trends and strategies within in the mold manufacturing industry. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Women Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.