Best Tool & Engineering is in the world of plastics welding and mold building. Images courtesy of Best Tool & Engineering.

Can you give us a snapshot of the shop’s history?

Joe Cherluck, President: Best Tool & Engineering Company started in September of 1991 with the purchase of Best Tool and Mold Company. We currently occupy two facilities. Plant 1 is injection molding with presses ranging from 75 tons to 500 tons, and Plant 2 is the engineering and tool manufacturing facility.

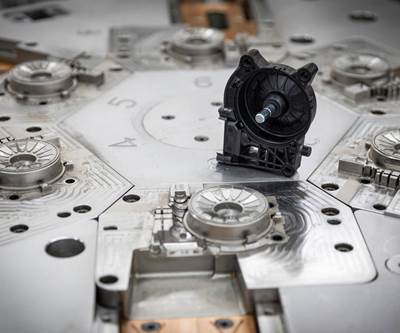

Our mold builds vary from low-volume prototype to full production quality to steel production tooling. Our specialty is high-volume aluminum tooling. We have been building this style of tooling since 1993 before it became “fashionable.” We provide engineering services, including product development, injection mold manufacture, injection molding and plastic bonding tooling in the form of vibration welding and hot plate welding.

Our expanding customer base includes automotive, medical, consumer product, foodservice and hardware manufacturers. We started servicing government contracts this year.

What do you view as your chief competitive advantages?

Cherluck: First, we are a small, flexible company with full engineering services. Our core engineering strength is the ability to redesign parts for manufacturability resulting in tooling and part cost savings. Second, our adaptability to new challenges. We are known for cutting steel while parts are still in the design stage in order to meet delivery requirements and for taking on projects that other shops turn down. Third, we work in a niche space from prototype to mid-level production.

With the current changes happening in the automotive market, I see mid-market molding growing—10,000 parts per year and under. I attribute this to the fact we already see it with the “niche” automakers such as Bollinger, Rivian, and other mobility companies. Their models are based on low volumes, yet they have similar needs as the higher volume automotive companies. I see the larger tier-one suppliers having issues scaling down to meet these needs.

What is your latest capital equipment investment?

Cherluck: Our most recent change in technology mirrors most other companies, which is a more substantial use of five-axis machining along with the purchase of a wire EDM and most recently, a hot plate welder. Drawing on our experience of building plastic welding tooling in the form of vibration and hotplate that dates to the 1970s, we incorporated this process this year.

Currently, there are few players in the low- to mid-volume market due to a lack of specialty knowledge and cost limitations. We used to only injection mold parts and build welding tooling, but now we have the equipment in-house to join the parts in the assembly process. We keep a close eye on all the other new technologies and adapt with demand.

Best Tool has the skill and craft, but what about business strategy?

Cherluck: My general approach to business was entirely turned on its side during the summer of 2019. I applied and was accepted into the Goldman Sachs 10,000 Small Business program. As a journeyman tool and diemaker, I have coolant and oil flowing through my veins. I was brought up in the shop, and I ran the business from the shop floor. The program is an MBA for entrepreneurs in a box (not their words but mine). It is a comprehensive four-month program covering every aspect of managing a business, which then led me to discover the Entrepreneurial Operating System (EOS) after speaking with my classmates. We’re in the early stages of implementation and I now have much more confidence and the tools that I need to plan for the future.

Best Tool & Engineering provides engineering services including product development, injection mold manufacture, injection molding and plastic bonding tooling in the form of vibration welding and hot plate welding.

What is your employee turnover rate?

Cherluck: Our turnover rate is under 10%. We have not had a difficult time attracting new employees due to our company culture. We start new “green” hires in the molding department. This gives us the ability to review their soft skills. If they work well in that area, then we allow them to train in the mold manufacturing area. If and when the team believes a new hire is a valid candidate, we offer apprenticeship training. We are currently investigating working with the SME Prime program and believe this will be an excellent pathway to early talent in the future. We currently employ 15 people within the two facilities, and we graduated our first apprentice, Meagan, this past spring.

What is the most exciting mold project your team has worked on together?

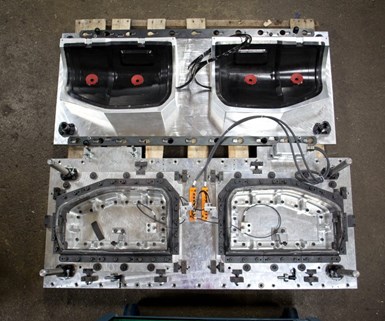

Stage 2 of the “pie” die with proprietary components removed. Images courtesy of Best Tool & Engineering.

Final “pie” product.

Cherluck: The most standout mold that showcases our can-do attitude was in the foodservice industry. I was approached by an employee of a vendor who had a relative working at a food service company. How is that for a twisted plot from the start? They were looking for a die to blank out pie dough.

Not a simple 2D cookie-cutter die though, because that is the only thing all the other vendors they approached could muster. They said, “We want it to look like a hand-crimped pie when it is finished.” I then asked them to show me what they wanted. They proceeded to hand-make an apple pie and said, “Make it look like this.”

We took the pie, froze it, and sent it to our 3D laser scan source—only after scratching my head and saying to myself, “What are you getting us into?” Pie dough does not move quite like plastic, but we were able to translate our plastics experience into this interesting challenge and develop a two-stage die to “hand crimp” a pie. There are other case studies on our website, but this one was the most fun.

Related Content

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

A Conversation with Big 3 Precision Products Inc.

MMT interviews Big 3 Precision Products Inc., a group that builds injection blow molds, one- and two-step injection stretch blow molds and extrusion blow molds.

Read MoreMichigan Moldmaker Produces Tools Onshore and Off

Rather than fighting offshore competitors, Liberty Molds has spent the last 15 years producing injection tools in both China and Michigan—and it’s paid off.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)