Medical Care and Electronics

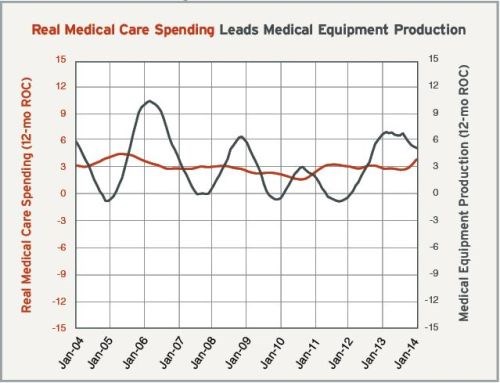

Industrial production of medical equipment has been growing at a decelerating rate since June 2013.

Medical Care Spending Growing Rapidly

From 2011 to 2013, real medical care spending grew at a slightly decelerating rate, but since the passage of Obamacare, such spending has been growing at a rapidly accelerating rate. In the first three months of this year, the month-over-month rate of change grew at the fastest rate since August–October 2002. (This is not a positive for the economy, as the dramatic increase in medical care spending has taken away from almost all other forms of consumer spending.) The dramatic surge in this spending in the first quarter also has resulted in a significant spike in the annual rate of change, which grew at its fastest rate since November 2005.

Industrial production of medical equipment has been growing at a decelerating rate since June 2013, however, the trend in medical care spending has already started to affect this production. Therefore, it is likely that its rate of growth will bottom out some time this summer. Then production will start to grow at an accelerating rate for the remainder of the year.

While the future should be good for the medical industry, our index indicates that it is still slowing down. The overall medical index has been growing at a generally slower rate since November 2012. New orders slowed down rather dramatically since that date, but appear to have stabilized somewhat in recent months. Production seems to be trending in a similar manner. Even though backlogs have contracted the last five months, they have improved compared to one year ago. This trend in backlogs indicates that capacity utilization and capital spending in the medical industry should reach higher levels in the second half of 2014.

For more information on the medical industry, go to gardnerweb.com/forecast/medical.htm.

Faster Electronics Production Predicted

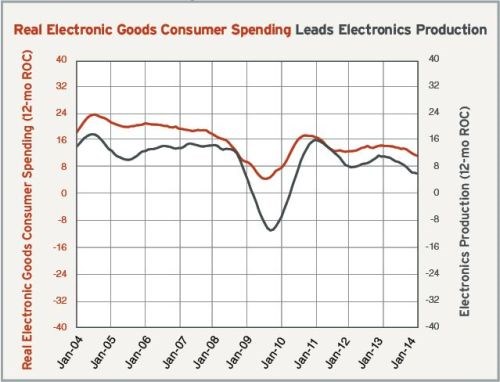

Consumer spending on electronics is hitting record highs in 2014, but, despite these record highs, the rate of growth in electronics spending has been decelerating since the early part of 2013. Slower growth in electronics spending is likely to continue unless personal incomes begin to grow at a significantly faster rate.

As a result of the slower growth in electronics spending, electronics production also has been growing at a significantly slower rate. In fact, this production is growing at its slowest rate since the summer of 2010 and may have slowed down too much relative to spending.

Our business index shows that electronics is one of the hottest sectors of durable goods manufacturing. The electronics business index has grown at an accelerating rate the first four months of 2014, and the industry is growing at its fastest rate since the index began in December 2011. New orders and production have been booming this year, and, from February through April, backlogs have been increasing at their fastest rate since the index began. These are all early indications that electronics production should soon grow faster as long as electronics spending remains reasonably strong. If the trends in new orders, production and backlogs continue, then capacity utilization and capital spending should increase sharply in the second half of 2014.

You can see all of our data on the electronics market at gardnerweb.com/forecast/electronics.htm.

Related Content

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.JPG;width=70;height=70;mode=crop)

_300x250 3.png;maxWidth=300;quality=90)