Laying the Foundation for a Modern Process

Changing thinking is perhaps the most difficult aspect of making the much-touted transition “from mold making to mold manufacturing.” However, it’s important not to lose sight of the technology required to make that happen.

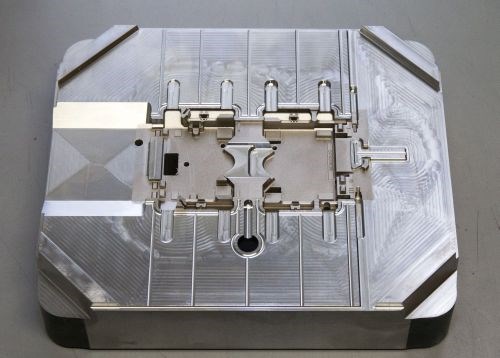

Extreme Tool & Engineering needed a high-precision machine to limit benchwork on molds like this one. This article details that machine's role in spurring a critical transition at the shop.

In the little more than a year I’ve spent covering this industry, I’ve heard one particular phrase repeated over and over again: “mold making to mold manufacturing.” This describes a change in thinking—in essence, the adoption of high-production principles to the relatively high-mix, low-volume environment that characterizes a typical mold shop. From what I’ve gathered, making that change is not only extremely challenging, it’s virtually required to succeed these days.

Yet, there's also a far more basic requirement to making this critical transition: the right technology. Standardizing processes often just isn’t possible with the machines of yesteryear.

For evidence of that, consider the experience of Extreme Tool and Engineering. Whatever else the shop may have done, it couldn't have fully changed its ways without the right machine, one precise enough to limit downstream benchwork. That’s because benchwork is done by hand, and anything done by hand leads to a level of variation that’s simply unacceptable for a modern mold manufacturing operation. This March-issue case study details how the 640V3 vertical jig borer from Yasda (represented by Methods Machine Tools) helped pave the shop's way.

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)