How to Prevent Seizing and/or Galling of Wear Plates, Slides And Core Pins

Using PVD/PACVD surface treatments can produce a desired tribological behavior without a costly change to design or material.

Whether you are dealing with machine parts, slide plates, ejector pins or lifters, friction is an undesirable factor in the performance and service life of components. Friction behavior is governed by how well the properties of the component surfaces perform under sliding conditions where galling or material transfer occur, or how well the substrate material is protected from corrosion. PVD and PACVD coatings can help solve some of the mechanical problems inherent to tribosystems. The use of PVD and PACVD coatings has proven to be advantageous in making these systems more efficient and economical.

Breaking It Down

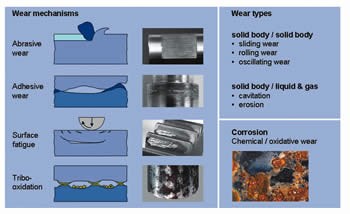

Let us first look at what causes failures to occur by examining tribological systems. Tribological systems consist of component surfaces that are in moving contact and thus become tribologically active. The amount of friction and wear is in direct relation to the materials that are coming into contact with each other. There are other factors that affect tribological systems, which include additives (lubricants such as oil, grease, water or water-based solutions), particulates (dust, metal fragments, dirt), temperature and loading (sliding, rolling, oscillating, pulsating). The effects of these mechanisms will produce friction and wear (see Figure 1).

PVD/PACVD

PVD/PACVD coatings have significant advantages over the mechanisms that lead to failure. A key benefit of PVD/PACVD surface treatments is that it may be possible to produce a desired tribological behavior without a costly change to design or material. Surface properties can be manipulated in order to provide certain advantages, such as:

- Longer service life

- Ability to tolerate greater loads

- Low cost maintenance

- Resistance to corrosion

- Environmental gains and conservation of resources

These are just a few attributes of the many cost-saving benefits that can be realized from PVD/PACVD coatings.

PVD/PACVD coatings are a fraction of a millimeter thick, harder than steel and are available in a wide variety of compositions to suit the application. PVD/PACVD surface treatments are applied in a precise, environmentally safe way by deposition from a gas or plasma state through a high vacuum process which ultimately enhances the tool's characteristics with good adhesion, high hardness, and wear resistance. The deposition temperatures can range from 200° C to 500° C and typically produce coating thicknesses that range from 1-4 µm. The process can in some cases be used in conjunction with other treatments, such as nitriding, boronizing or ion implanting. A discussion of the application with your coating provider is very important to make certain that the process is compatible with the materials (see Figure 2).

Carbon and Noncarbon-Based Coatings

For the purposes of this discussion, we can divide component coatings into two groups, carbon-based and noncarbon-based coatings. The carbon-based group consists of the DLC (diamond-like carbon) family of coatings. The non-carbon-based group includes coatings such as Chrome Nitride (CrN), Titanium Nitride (TiN), and Titanium Aluminum Nitride (TiAlN). The benefits of these two groups can be weighed on the application and failure modes (see Figure 3).

Carbon-based coatings are highly resis-tive to adhesive wear. The application of DLC-type coatings is usually applied by reactive type sputtering. The low coefficient of friction of the DLC coatings can sometimes help reduce surface fatigue. The harder versions have been shown to exhibit protection against abrasion and adhesive (scuffing) wear. Typically, these coatings can be applied at temperatures at or below 250° C (see Figure 4).

Noncarbon-based coatings are usually applied by ion plating or arc evaporation. These coatings are usually applied at higher temperatures of up to 500°C. If a lower temperature process is needed, please check with your coating supplier for availability. The noncarbon-based coatings are generally harder, so they protect more against abrasion and also are suitable for adhesive wear protection.

Component Surfaces

One thing to remember is that no matter how well the physical makeup of the coat-ing appears, the component surface must also have good preparation and quality. Surfaces must be prepared to give the coating an opportunity to perform at an optimum level.

Material surfaces must be free of resins, waxes, paint, oxide skin and grind marks. Even the use of polishing compounds must be reviewed. Overly aggressive polishing techniques using oil-based solutions can in most cases leave a contaminated surface, and therefore, must be thoroughly cleaned before coating. Ground surfaces can leave peaks and valleys in the substrate. Because coatings are thin, they will mirror the surface they are applied to. The peaks and valleys in the substrate can affect the contact areas and thus produce premature failure.

Summary

PVD/PACVD coatings can greatly en-hance component life as well as productivity. These thin film coatings can:

- Protect dry running systems

- Reduce corrosion

- Lessen the need for lubrication and maintenance

- Enhance reliability and service life

Case studies have shown that systems or parts can be optimized through the choice of the right coating. The variety of options makes it possible to pick the coatings that yield the desired results. Make sure you work closely with your coating provider to devise the right solution(s) for you (see Figure 5).

Related Content

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreFive-Axis Laser Machining Makes Digital Mold Textures Possible

Mold manufacturers using laser technology can play a vital role in brand protection, recyclability and traceability efforts with new digital mold textures.

Read MoreMost-Viewed Content of 2022

The most popular MoldMaking Technology content according to analytics reports over the past 12 months.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreRead Next

Tough Coatings Control and Extend Mold Life

Moldmakers can solve tough productivity problems by applying next-generation coatings.

Read MoreHow Surface Treatments Keep Molds Operating Longer

Important tips and information about mold coatings to help you achieve the level of production that you and your customers desire.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

_300x250 4.png;maxWidth=300;quality=90)