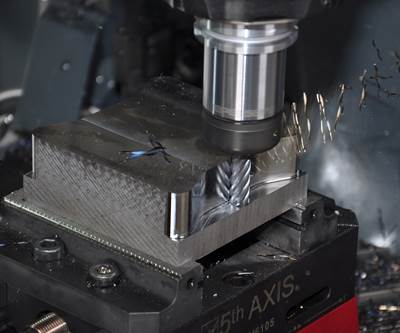

How to Hard-Mill Effectively

These are five rules for improving cutter performance and cutter life while maintaining tight tolerances during hard milling.

Hard milling requires the utmost attention to detail to achieve maximum performance and tool life and tight tolerances down to 0.0001 inch. These tips help machinists get the most from hard milling.

Maintain a constant chip load and feed rate. Machine tools rapidly fluctuate feed rates when machining complex surfaces and cutter paths, which drastically reduces tool life. Machinists must understand that when machining complex surfaces, machine tools do not reduce rpm in conjunction with feed-rate reductions. So, if the machine cannot maintain programmed feed rates 80 percent of the time, operators should record the average feed rates and then reduce the feed rates and rpm accordingly. For example, if an operator programs a 30,000 rpm and a 150-ipm feed rate, but the machine can only maintain an average feed rate of 75 ipm, the operator should reduce the rpm to 15,000. The subsequent reduction in rpm will increase tool life by 50 percent and impact cycle time negligibly.

Do not leave extra stock for finishing. When machinists are machining tool steels above 48 HRC, extra finish stock will reduce output and wreak havoc on surface finish and tool life. A general rule for finish-stock allowance is 1 to 2 percent of the finish-cutter diameter. Most cutting-tool manufacturers base their finishing cutting data on 1 to 2 percent of the tooling diameter engagement, so leaving more than that decreases productivity. For example, when using a tool with a 0.5-inch diameter, leave no more than 0.005 to 0.010 inch of finish stock.

Leave consistent stock on all surfaces. After a machinist roughs a complex surface, he or she should run a rest-rough and semi-finish tool path to ensure consistent finish stock on all surfaces. For example, when a machinist roughs out a complex 3D surface using a 12-millimeter ball-nose end mill, and the intended finishing cutter diameter is 8 millimeters, a safe practice for ensuring 0.003 to 0.006 inch of stock on all surfaces is to rest-rough with a 10-millimeter ball-nose end mill and then semi-finish with an 8-millimeter ball-nose end mill. Then the machinist should finish mill with a new 8-millimeter ball-nose end mill to ensure all surfaces have a consistent surface finish. This practice also extends finishing cutter life and enables the machinist to use the finishing ball-nose end mill as a semi-finishing tool when the life of the finishing tool ends.

Use strong, precise toolholders. High-precision holders are crucial when hard milling to achieve maximum tool life. Run-out must be limited to less than 0.0004-inch to maximize tool life. Machinists can achieve this level of precision with most shrink-fit holders, milling chucks, high-precision collet chucks and select end-mill holders. A precise holder ensures process accuracy, whereas a less secure holder can cause unpredictable tool life and produce out-of-tolerance surfaces.

Follow recommended cutting parameters. Cutting data is optimized according to the tool’s design and for specific material groups, as some common hardened tools steels present unique challenges, so machinists should use recommendations as a starting point. The machinist can make modifications depending on the application.

About the Contributor

Jay Ball is the product manager for solid end mills for Seco Tools.

Related Content

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreRead Next

The Hidden Complexities of Optimized Roughing

Consider these factors for developing an optimal process using optimized roughing strategies.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)