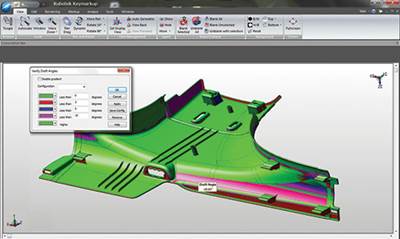

Innovative and performance-based part geometries often require complex injection molds, and that means engineering meetings. Your shop’s toolmaking, designing and project engineering resources are primarily directed and funded through existing work-in-progress. However, their input and collaboration are essential in acquiring new opportunities. Interrupting their workload to redirect their time on prospective projects is part of being a growing tool shop. The scope of the request for quote, its short-term and long-term financial impact, and the capacities of your shop (on the concrete and on the carpet) all play a role in your strategy when developing a significant proposal. Images courtesy of Dynamic Tool Corporation.

For many in the business of plastics manufacturing (tooling/molding), one of the most painful jobs is getting plastics manufacturing business. Everyone loves new business, whether from an existing client or a new customer. Marketing and salespeople love bringing in the Request for Proposal (or Quote; RFQ). It is, after all, the way many of them are commissioned or bonused.

The C suite loves RFQs because each one is an opportunity to make more money and grow the business. Certainly, nobody on the production floor has any issues with prospects and customers sending inquiries for projects. More work means more pay for more years.

The only folk who cast a dubious and disdainful eye at an RFQ are those who must formulate the quote. This is understandable because so many requests begin life as half-baked, deadline-based cattle calls for “estimates.” Whether you are a moldmaker or a molder, how many times have you heard, “We don’t need an exact quote, a guesstimate will be fine — but we need it right away.” This scenario sounds reasonable until reality sets in.

Reality sets in a few weeks or months after you submit your rushed budgetary estimate. The proposal you submitted was as detailed as it could be based on the customer data. What we typically get is:

- The design isn’t final, but we still need a quote.

- There are geometry issues that will be addressed later.

- Don’t worry about draft or radiuses or exact gating locations.

- We only have a rough idea of projected annual volumes. So quote one-, two-, four- and eight-cavity molds.

- We might want to put a label or some kind of information in this area, so consider in-mold decorating, pad printing, heat transfer or engraving as a possibility. Unless you can just laser etch the part after molding. Include a cost for each.

- We’re not 100% on a material yet, but that shouldn’t matter much, you can always adjust for shrink.

Analyze Quoting Approach

We all know that if you don’t submit a proposal, you don’t have a shot, but the question remains: how should we quote? We can make realistic assumptions based on our experience. For example, we know based on the geometry presented that the production mold will benefit from a more sophisticated strategy for temperature control, so we add the cost of machining and materials for conformal-cooled inserts. We might want to consider steel selection as well. Have the other shops in the running done the same? If not, they will be several thousand dollars lower than you right out of the gate, even though your idea will reduce cycle time or improve part stability.

Did you identify any potentially challenging steel conditions? Should you address those and make design revision suggestions? Should you quote based on what you know or based on the information presented? Have you ever submitted a well-researched proposal where you and your team applied best design practices and your know-how only to find out that the customer went with Marv’s Tooling & Bait Supply because Marv came in at “half the price?”

Consider that the individual driving the RFQ event is often not the person deciding which source gets the work. Did the RFQ come with a fill-in-the-cells spreadsheet? In a quoting scenario where several prospective sources are involved, all your work may ultimately be judged by only two of those cells: final cost and lead time.

You likely noted in your accompanying email and through conversations with your contact that you are including an amount to cover a round of steel adjustments and an additional sampling event to address that challenging steel condition noted previously. However, that information is not on the spreadsheet. And what do you suppose the Procurement Director at the ABC Corporation knows about a challenging steel condition? That Procurement Director’s annual bonus is based on cost reductions that are backed by documentation. They get no credit for buying a robust tool design to enable productivity and ease of preventive maintenance.

The only absolute we have is to get as much information as we can, as early as we can, and document the gaps and the impact that the missing information has on your proposal.

The work and tasks that are executed in the development of a proposal to build a world-class injection mold shouldn’t end with the submission to the RFQ. Each project you choose to target presents a tremendous learning experience for your next generation. Make certain to include appropriate members of your team and expose them to the various phases of creating a formal proposal: evaluation of design, the consideration of best practices for mold layout and steel selection, and planning for efficient preventive maintenance, to name just a few. Allowing team members to see the big picture of quoting (the technical and the business side) benefits your shop in many ways.

Understand OEM-Brand Owner Expectations

Have you ever had the opportunity to physically visit a large OEM and spend time with members of the design and development staff and project managers? Your company likely has an engineering group or a design team comprising a handful of people, whereas a large OEM with a portfolio of products may have an entire building of project managers, engineers and designers.

Dozens and dozens, if not hundreds, of highly educated people who are researching, think-tanking, testing, trialing, virtualizing, prototyping and dreaming up their company’s next product release. Perhaps it is a new product entirely. Maybe it is a significant improvement in functionality over the existing release. It could be a redesign of a legacy product making use of different materials for light-weighting initiatives. It may be a copy of a bestselling competitive product without looking like a copy. Large brand owners must constantly develop new products and improve existing products.

All of that research and development activity leads to lots and lots of quotes. Every idea cannot be funded to fruition, so those engineering and design teams must pitch ideas to the company’s executive management team for review and consideration. Depending on the circumstances and the market, launching a new product or a significant revision to an existing product is a substantial investment of time and money. For executive leadership to judge in which projects to invest, cost models need to be created, which means RFQs from tool shops, custom molders, material suppliers, component distributors and equipment suppliers. Nearly every speculative product will generate requests for quote.

When I first started in the plastics industry, I asked and was told by a category leader at a large consumer products OEM that its average launch is about one new project out of 12 potentials. That means that of 12 individual projects researched, designed and quoted, only one will get the green light. When I asked that question at a medical device OEM, the answer was one out of sixteen. Of course, there is no standard, but this gives us an idea of what is on the plate and what is at stake.

The best we can do is gain an understanding of the available project scope and develop a proposal based on how attractive that job and that customer is at that time.

Build the Mold Buyer Relationship

Whether you love requests for quotes or hate them, you have to deal with them and effectively manage and respond to them. It’s more complicated than “Get all the information you can.” We need to determine the nature of our relationship with the mold buyer.

Are the questions we ask and the insight we provide valued by customer engineering and procurement? Unless you know that the customer’s engineering department plays a significant role in decision-making, purchasing will not consider all suggested areas of improvement.

What is the background/technical wherewithal of the OEM contact? Is this a gatherer of emails and compiler of responses? Can they answer any technical questions? If the person with whom you are directly dealing doesn’t know what annual production volumes are, whether or not the company has a resin contract or a preferred hot runner supplier, and they have no idea what you mean by steel safe, there is a strong chance that your wisdom and design for manufacturing (DFM) time will fall on deaf ears.

Are we being compared to similarly capable sources of supply? This is based on the capability and experience of the customer’s engineering department. The smarter they are, the fewer tool shops they deal with. If they’re good, they know which shops to engage based on geometry, size, and lead time. They won’t even accept a proposal from Marv, no matter the price.

The best we can do is gain an understanding of the available project scope and develop a proposal based on how attractive that job and that customer is at that time. If you must submit your quote on a spreadsheet, and the spreadsheet consists of cells demanding your business information (hourly rates for design, labor, machining, material mark-up, margin), understand that price is the only thing that matters.

The OEM’s engineering department may desire and appreciate your design for manufacturing efforts, but your DFM input will not be acknowledged or valued by procurement. This approach encourages one to quote low and systematically charge as things progress and then stall throughout the build and sampling events.

Does this conversation after the first run of parts sound familiar?

Customer: “Why does the surface look like that?”

Moldmaker: “That’s sink. The features you designed on the other side are causing that. We can fix it, but the tool’s gotta go back to the shop!”

Who wants to run a business that way? You’re not misleading your customer, but you are allowing them to fail or struggle when you could have helped to prevent it. Do you point out design flaws before submission of your proposal? Do you price the job low to get it and then educate them on design improvements and charge for them? The relationship you have determines the course.

If you are among a pool of shops quoting a job, and they only look at your proposal’s final price, and lead time, your investment in supplying design best practices and improvements may be lost or given to their current low-cost solution. An existing customer that has a history of contributing to your revenue stream and performance should be given the benefit of your experience and intuition every step of the way.

The only absolute we have is to get as much information as we can, as early as we can, and document the gaps and the impact that the missing information has on your proposal. In the end, the laundry list of required quoting-related information is not complicated; it follows a logical progression. Ask these four questions:

- What are the individual part’s size, shape, critical geometry and surfaces?

- How many are needed annually and for how many years?

- What type of plastic is required for it to do its job?

- What is required after molding?

Alligator Holdings LLC

John Berg is Director of Marketing for Alligator Holdings LLC, a growing group of manufacturing companies focused on innovative product and service development.

john.berg@alligatorcompanies.com

Related Content

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreMMT Chats: Acquisition Trends and Lessons for Mold Builders

Jim Berklas is a former full-time M&A lawyer for several of the largest private equity firms in the country and has 25 years of M&A experience and 200 closed transaction. Today, he is founder and M&A Leader with Augmented Industry Services. He joins me for this MMT Chat on mergers and acquisitions trends and strategies within in the mold manufacturing industry. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

Conquering the Quoting Challenge

Adding the right multi-CAD viewer to your quoting process helps improve customer communication, secure new business, and save time and money.

Read MoreCosting Challenges and Strategies

Mold manufacturers should automate the mold costing process to improve quote accuracy and accelerate RFQ response.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)