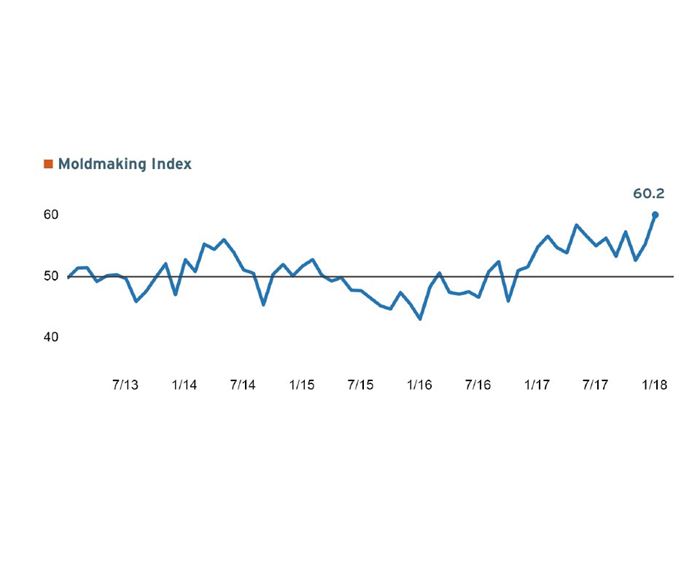

Gardner Business Index: Moldmaking Starts 2018 Breaking Records

New orders and production lift Gardner Business Index: Moldmaking, at 60.2 for January.

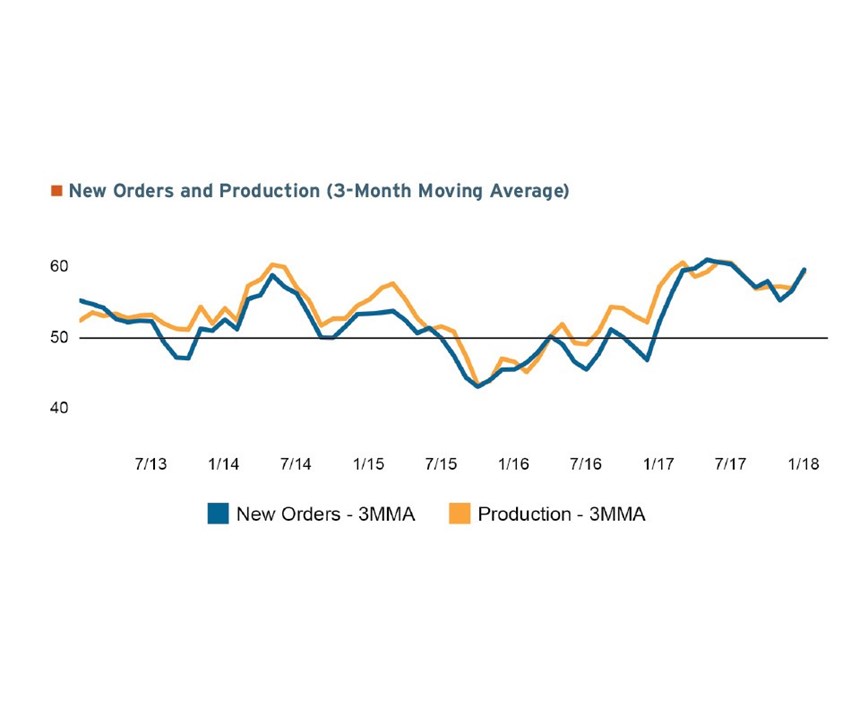

Registering 60.2 for January, the Gardner Business Index (GBI): Moldmaking expanded at its fastest pace in recorded history. Compared to the same month one year ago and to the average reading for 2017, the Moldmaking Index increased by 9.0 percent and 7.6 percent, respectively. Gardner Intelligence’s review of the underlying data for the month revealed that new orders jumped drastically in January with the new orders reading increasing approximately 12 points since December. The reading for production also showed significant expansion. New orders and production lifted the Moldmaking Index higher while backlog, supplier deliveries and employment minimally impacted the Moldmaking Index. Exports was the only component that significantly lowered the Moldmaking Index during the month. However, no components contracted.

For a second month in a row, new orders expanded faster than production, and it did so by a considerable margin. Reviewing past trends from the Gardner Business Indexes reveals that when growth in new orders exceeds growth in production, it is typical for manufacturers to experience additional growth in future months because manufacturers are adjusting to increased demand.

About the Author

Michael Guckes

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

MMT Chats: Marketing’s Impact on Mold Manufacturing

Kelly Kasner, Director of Sales and Marketing for Michiana Global Mold (MGM) talks about the benefits her marketing and advertising, MGM’s China partnership and the next-generation skills gap. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)