Flexible Moldmaking

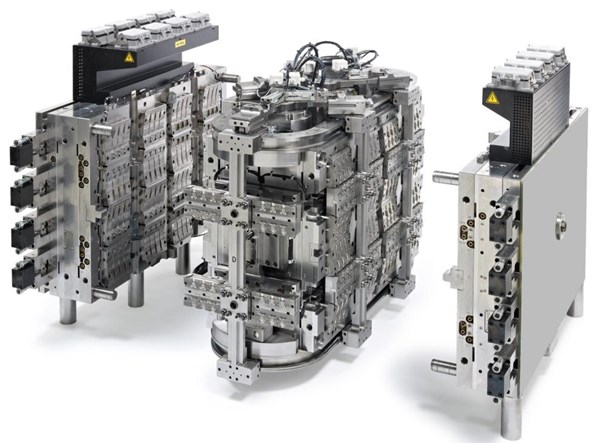

An innovative approach to multi-component injection molding can be seen in a “Flexi-Cube” mold--the first mold of this type was delivered for a 3-component handle in a 24-cavity layout. Here is a glimpse of this particular 5-station mold.

An innovative approach to multi-component injection molding can be seen in Boucherie's “Flexi-Cube” mold. The first mold of this type was delivered for a 3-component handle in a 24-cavity layout.

To give you a glimpse, this particular mold is a 5-station mold: Station 1 (24 cavities for the injection of the first material); Station 2 (cooling); Station 3 (24 cavities for the injection of the second component); Station 4 (24 cavities for the injection of the third component); and, Station 5 (outside the mold for product ejection or removal during an active molding cycle).

Although the product features a relatively big wall thickness, an overall cycle time of only 15 seconds was achieved, according to the company. The core of this mold is a stack design with a central, stationary cube around which circumference various stations are provided and which are linked by a transport-system that travels around the cube.

For more information click here.

.jpg;maxWidth=300;quality=90)