As some shops have already discovered, femtosecond laser technology represents a new frontier in moldmaking. The aim of this new laser is not to replace traditional machining methods; instead, it complements them in a way that ultimately leads to increased productivity for mold shops and manufacturers alike.

Femtosecond lasers are, as the name implies, lasers with pulse durations in the femtosecond range (one quadrillionth of a second), a pulse length that puts these lasers in the category of ultrashort pulses. One prominent advantage of this extremely short pulse length is the reduction of heat absorption, a quality that made femtosecond lasers useful for medical applications, particularly ophthalmological procedures such as LASIK.

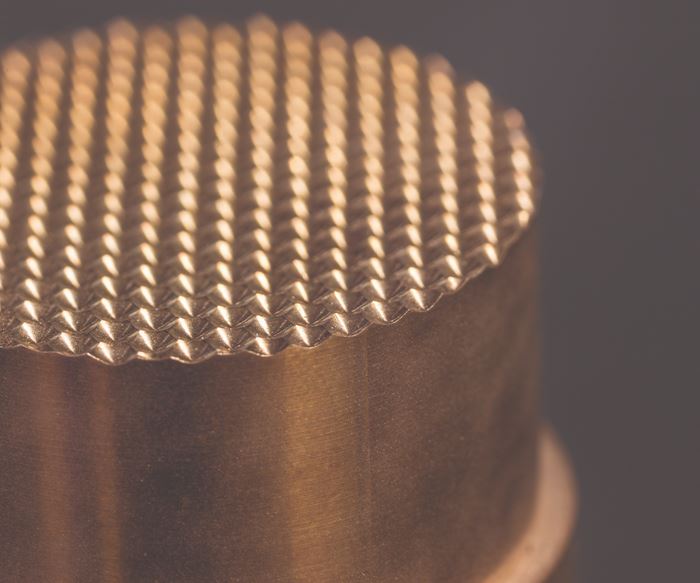

Naturally, the avoidance of heat transference and a high degree of precision make femtosecond lasers excellent tools for mold production. The ultra-short pulse duration of the laser prevents materials from reentering a fusion state resulting in true ablation while engraving is ongoing. The ablation process vaporizes the material, eliminates burr formation and provides an exceptional level of finish. While nanosecond lasers produce sufficient heat to harden the surface of materials and damage coatings, femtosecond lasers avoid these issues, making them ideal tools for heat-sensitive parts.

Today, the market offers a femtosecond laser machine with a working distance configurable from 73-300 mm, which makes for close work for traditional machining but incredibly generous for laser texturing and other moldmaking applications.

Laser-Focused on Working Distance

Unlike die-sinking EDM or conventional micromachining, laser micromachining has relatively few requirements. The first is simple line-of-sight, a far less restrictive requirement than one finds with other machining operations. As a non-contact tool, lasers can reach places otherwise impossible even with the smallest of diameter spindles and can create small mold features at working distances often unobtainable with ram EDM.

The second laser requirement involves working distance. Because lasers use amplified light as the cutting tool, they rely on lenses and their corresponding focal distances to the workpiece. Many of the ultrashort pulse laser options for micromachining on the market have a working distance of only a few millimeters owing to a working spot size just 1-3 microns in diameter. This allows for amazing detail when hole drilling, cutting or creating micro-structures on flat or tubular surfaces but constrains the laser movement to third or fourth axes, ultimately limiting their capabilities.

Today, the market offers a femtosecond laser machine with a working distance configurable from 73-300 mm, which makes for close work for traditional machining but incredibly generous for laser texturing and other moldmaking applications.

At these distances, laser pulse spot sizes range from 18-70 microns at full power, depending on the lens option, but refined parameters can yield spot sizes in the single-digit microns. These lasers also excel in terms of angles of attack, with full five-axis movement and high-quality cuts remaining possible at up to 70-degree angles.

Unlike the speeds and feeds one considers in milling and turning, the primary parameters used in laser operations involve the laser’s power output, its frequency and the speed of the galvo mirrors that control the laser’s movement across the workpiece.

Manipulating Laser Parameters

Laser ablation, whether used for engraving, texturing or machining part features in molds, requires a different approach to traditional material removal operations. Unlike the speeds and feeds one considers in milling and turning, the primary parameters used in laser operations involve the laser’s power output, its frequency and the speed of the galvo mirrors that control the laser’s movement across the workpiece.

Generally speaking, power is the most straightforward of these factors. If you set the laser’s power to 20 percent, in most cases, you get an output of 20 percent. Modifying the laser’s frequency, the oscillation of the laser’s energy controlling wavelength has a more complex relationship with depth of cut and detail.

To understand frequency, imagine ocean waves. Large waves have loads of power (energy) but occur less often, whereas you could see dozens of small, less powerful waves in the same period. So, low frequencies can remove material fast and aggressively, and higher frequencies will often create higher quality cuts with a slower material removal rate.

Similarly, there is a correlation with the speed of the galvo mirrors movement across the material surface, affecting both removal rate and surface quality. By managing these key factors, operators can vary the depths-of-cut per slice and impact the quality of the ablated surface significantly.

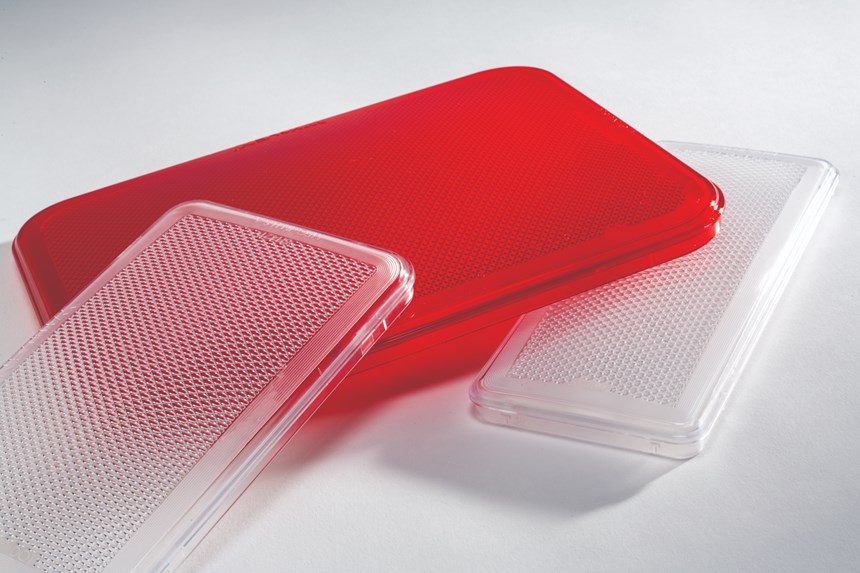

Smithfield, Rhode Island-based Providence Texture is one shop that mastered the manipulation of laser parameters and has already begun taking femtosecond laser technology used to the next level with its machine for micromachining part features. The shop produces a vast range of textures, including those with extremely low Ra-value surface finishes, and generates numerous laser-only textures and patterns.

Many of these part features are deceptively simple, such as a V-shaped groove to add additional pressure to a gasket seal that may be as little as 0.005 inches deep, or one to two-millimeter thread features on a plastic syringe barrel mold. Both femtosecond and nanosecond lasers can create these features faster and more economically than typical die-sinking operations. Furthermore, femtosecond lasers can create micron-level features that demand tolerance ranges too difficult or even impossible with traditional techniques.

Providence Texture has also found that a strategic key to achieving the highest levels of part precision and laser machine production is automation. With its palletized automation system and custom fixturing designed around the laser’s capabilities, the shop keeps its repeatability within ±3 microns. Automation also makes it possible for this shop to handle a high-mix, low-volume manufacturing environment while maintaining the capacity for high-volume production when necessary.

The combination of laser technology and a robot automation solution are critical for the shop. “With our custom fixtures, we can program a reference offset and know that we’re within two to three microns of accuracy when that fixture goes back in front of the laser. That kind of precision is key when you’re working at the micron level. We maintain the ambient shop temperature within four degrees to ensure the greatest possible accuracy,” President and CEO Matt Melonio says.

Throughout only a few decades, lasers have become an indispensable tool for moldmakers who have used this technology to achieve textures and precision beyond the capabilities of traditional milling or EDM machines. Today, laser micromachining and texturing have taken another big step forward thanks to femtosecond lasers, but laser technology pioneers will continue forging ahead in search of methods for pushing the limits of the technology.

About the Author

Jon Carlson is Product Manager, Advanced Manufacturing for GF Machining Solutions.

For More Information

Providence Texture

401-642-9490 / matt.melonio@providencetexture.com / https://providencetexture.com/

GF Machining Solutions LLC

847-955-7145 / jon.carlson@georgfischer.com / www.gfms.com/us

Related Content

How to Use Diffusion Bonding to Optimize a Mold’s Thermal Performance

Joining dissimilar metals has tremendous potential for conformal cooling, but to successfully use diffusion bonding, a mold builder must understand the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreRead Next

Laser Ablation for Surface Texturing

How moldmakers can improve the level of control exerted in surface texturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)