In moldmaking, traditional production planning starts off with mold design, machine scheduling, outside services scheduling, assembly, quality, and then finishes with the hope of hitting the promised delivery date. With enough experience, most moldmakers get pretty good at predicting the future. But, is pretty good enough?

Many leading shops are considering enterprise resource planning (ERP) to improve their competitive position. When implementing ERP, shops conventionally cram the schedule full of the required operations to complete the job as quickly as possible. This may not be the most effective method. Consider turning tradition upside down and starting with the end in mind by using the delivery date and scheduling the process backward. For one mold builder, the overall benefits of this approach have been amazing.

Three years ago, Quest Industries (Quest) began the journey of ERP implementation in earnest. In 2006, it started using an ERP system but never really tried to understand all of its capabilities. As the company grew, Quest Industries President Dennis Hoover realized that he needed more information instantly to make the decisions necessary to take the company to the next level of performance. A year after searching for a solution, the Quest Industries team selected Exact Synergy Enterprise (ESE) combined with its existing JobBOSS ERP to integrate, manage and control its workflow.

Despite all the hard work, the company was not impressed with the results two years into the implementation. The shop had more information, but there was little change. Quest Industries developed a lot of numerical information regarding its productivity, machine use and material resources but could not get the data into a format that would enable the shop to predict delivery accurately. The team was not fully using the Synergy system. It was not until Hoover discovered Joshua Eddy with business management consultant The Attivo Group that things started to take off.

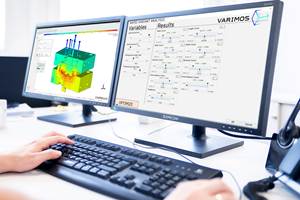

JobBOSS ERP is Quest Industries’s primary ERP system, Unipoint is another system that Quest Industries uses in its quality department, and Synergy is the glue that ties all the information together. Synergy visualizes the collected data and improves communication among all parties. The system coordinates workflow management, document management, project management, customer relationship and business process management across the entire company.

Approaching ERP

Implementing an ERP system company-wide requires a lot of planning, effort and monitoring to ensure success and to minimize problems. Quest Industries spent a year working with an outside consultant to implement its ERP system fully. The consultant’s experience saved time and prevented costly mistakes that someone with less experience would make, according to the company.

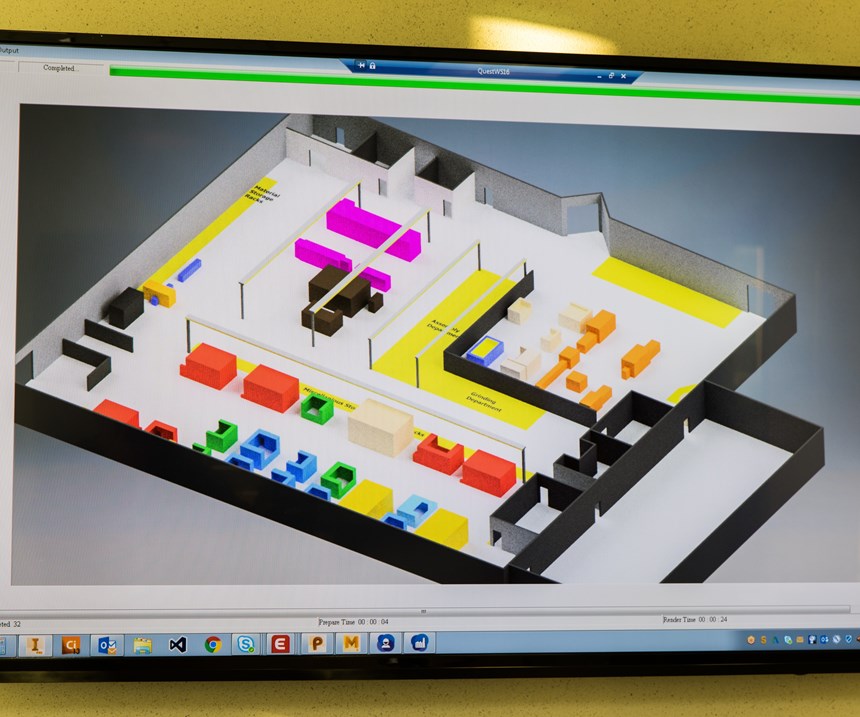

Quest Industries’s implementation was not easy. The shop had to clean up a lot of legacy data and collect information from the existing ERP system, spreadsheets and manual records. The shop also needed to update the internal network and servers to accommodate the new system and install monitors and computers into all the manufacturing cells.

Hoover knew that in conventional strategic planning, one starts with the goal, develops the objectives and then adds tactics to achieve the goal. For example, to achieve the goal of increasing sales by 20 percent, one needs to work backward and figure out how many additional projects are needed and how many prospects are required to fill the sales pipeline. Hoover and his company followed this same logic and started looking at job planning with the delivery date and working backward.

The ERP system is only a tool in Hoover’s quest to continuously improve performance. He believes it is the people who make it happen. “It’s easy to forget that the success of the system depends on the people who use it,” Hoover says .Hoover lives by the words of Author Stephen Covey, who said, "An empowered organization is one in which individuals have the knowledge, skill, desire and opportunity to personally succeed in a way that leads to collective organizational success.”

“An empowered organization is one in which individuals have the knowledge, skill, desire and opportunity to personally succeed in a way that leads to collective organizational success.” -Author Stephen Covey

Implementing ERP

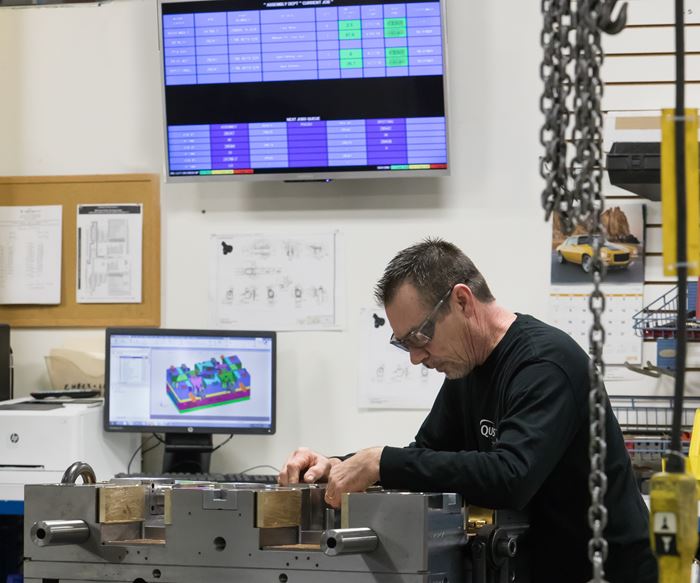

Today at Quest Industries, computer screens are installed at every manufacturing cell, shop floor personnel see everything happening in real time, and project schedule changes are instantly recognizable. Communication improved because everyone is working from the same real-time information. The entire team has visual accountability from monitors installed at each workstation.

Employees no longer need face-to-face meetings to update everyone, which has reduced interruptions by 70 percent. Now, updates are provided through the ERP system. And, operators no longer interrupt a program manager to report a delay. Instead, program managers and operators manage communication using Skype to report problems and delays without leaving their workstations.

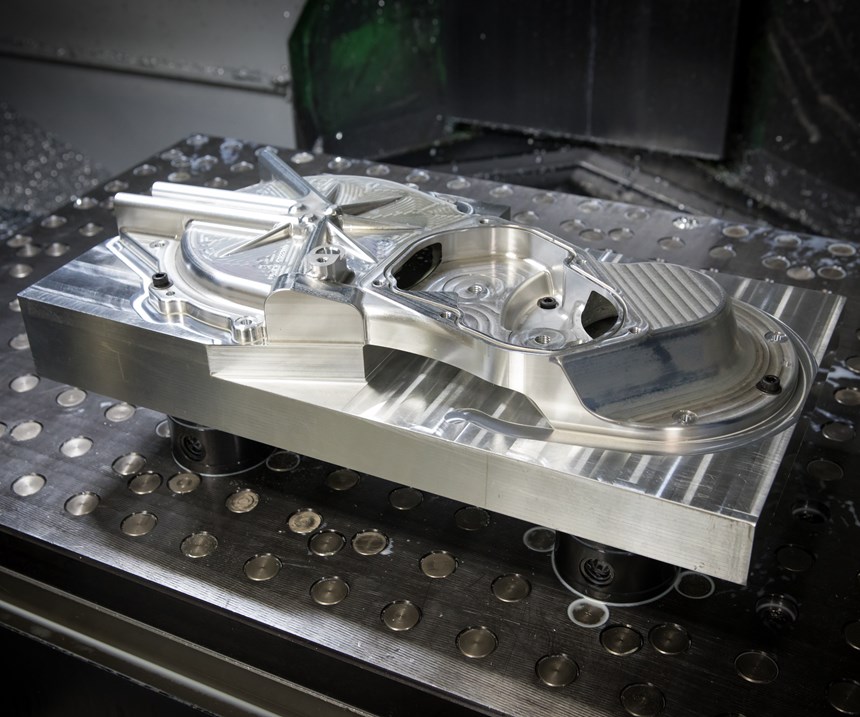

Quest Industries is an unusual moldmaker because it builds molds and does prototype and detail machining. The scheduling requirements for the wide variety of projects at Quest Industries are very different from the scheduling requirements at other shops. Production molds, prototype and detail machining work well with backward scheduling methodology while repetitive jobs and extremely hot jobs work better with forward scheduling. Hoover and his team spent a year evaluating whether to use forward or backward scheduling, as ERP systems require the use of one method. Since building production and prototype molds is the majority of the company’s work, the shop chose backward scheduling.

Improving Performance

ERP software, scheduling and schedule adjustment are critical to maximizing machine use when it comes to correctly scheduling the constantly changing mix of detail machining and molds. Today everyone has visibility. For example, as soon as an operation is complete, the software automatically schedules it to the next workstation. Operators no longer need to leave their workstation, walk to the program manager and receive their next setup.

Inspections are now paperless with Unipoint Mobile. Tablets at the machines and on the shop floor benches collect data. In multiple part runs, like detail machining and high-cavitation molds, Synergy sets the inspection frequency and retains the time stamp to avoid rushed reports at the end of each shift. If the staff does not perform inspections at the scheduled intervals, Synergy sends out alerts for corrective action. Synergy is the communication command center that expands the performance of the ERP system by integrating JobBoss and Unipoint.

As a bonus, machinery and inspection equipment, preventive maintenance and calibration are now scheduled into the workflow, which results in improved performance and reliability. The old method of waiting until there was open time for a problem was far more costly than this new, proactive approach.

Changing Culture

The biggest benefit to Quest Industries’s project scheduling is to the company’s culture. Before ERP, decisions dictated to the shop floor. Today, the shop floor personnel can help make decisions using their firsthand perspective and understanding of machine capabilities. For example, when a project hits the schedule for which the operator thinks too much or too little time has been allocated, he or she reports the discrepancy. This results in better machine efficiency and a significant reduction in outsourcing.

“We’ve eliminated paper travelers,” Hoover says. “The software creates digital travelers that are automatically updated as soon as someone makes a change to a project. This eliminates the problem of lost or multiple outdated travelers on the shop floor, reducing the chance for errors.”

Managing the change has been the most challenging part of the implementation. It required a cultural shift. This came as a surprise to Hoover. To him, scheduling by starting with the promise date and working backward seemed superior to what they were doing. However, as with most instances of cultural change, it was difficult to get everyone moving in the same direction. “It wasn’t until after we had a few small successes that we achieved widespread adoption,” Hoover says.

Often, people find it difficult to switch to new ways of doing things if the benefit is not obvious. With an ERP system, many employees’ level of responsibility increases because the shop floor drives more of the decision making. As new information becomes available, processes evolve. It becomes easier for people to embrace the change as the system proves itself.

Hoover’s philosophy is “there is always a way to do it better, and we have to find it. We hire smart people who care and channel their drive for success into our business. We work with the knowledge and satisfaction that each of us makes a difference.” The implementation and success of ERP have been a big step in this journey.

Taking the Next Step

The next step for Quest Industries was centralized purchasing, so a single department directs all materials, supplies and outside services. Previously, department managers were responsible for obtaining their supplies. “Centralized purchasing gives us better control of inventory and reduces overhead expenses and outsourcing,” Hoover says.

By consolidating purchasing under a single department, Quest Industries can negotiate better prices, consolidate shipping costs and develop more favorable purchasing terms. Internally, systematic accounting of materials will prevent shortages and duplicate inventory, reducing Quest Industries’s overall stock.

Hoover says, “We have come a long way with our ERP implementation. We are getting more done in less time. Our quality has improved and, ironically, we don’t feel like we are as busy as before because the firefighting has diminished. We have become a forward-thinking company.”

About the Contributors

Todd Schuett is founder and president of Creative Technology Corp. Tom Barrett is in charge of strategic planning and marketing for Creative Technology Corp.

Related Content

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreSimulation is a Process, Not Just Software

To reap the benefits of simulation, you must view it as a process requiring you to change the way you work in part and mold design.

Read MoreTen Things Mold Builders Should NOT Do

What you don’t do can be just as important as what you do, sometimes even more so. One thing great mold builders do is take note of what gets in the way of their success and stop doing it.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)