Do You Want to Know Why Plastic Parts Warp?

I have worked with Tim Lankisch, director of engineering at CAE Services on numerous technical articles and educational videos in MMT focused on the value of simulation. Yesterday Tim came off the printed page and went live in an MMT webinar that analyzed why plastic parts warp. View archived recording now.

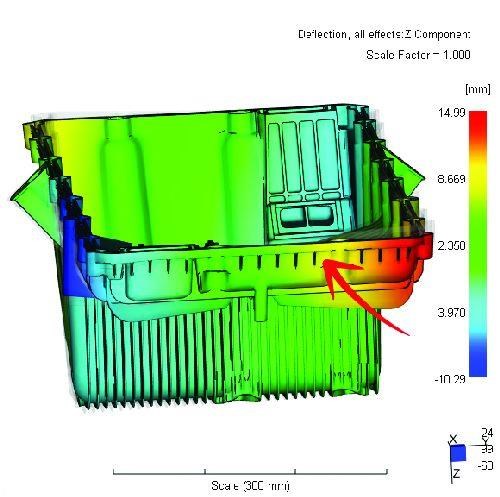

I have worked with Tim Lankisch, director of engineering at CAE Services on numerous technical articles and educational videos in MMT focused on the value of simulation. Topics have included using simulation to control flow in your injection molds, to bias your mold and reduce warpage, to predict high-conductivity insert performance and to determine the right valve gate sequence, to name of few. Yesterday Tim came off the printed page and went live in an MMT webinar that analyzed why plastic parts warp. In this webinar, Tim helped attendees understand how the manufacture of plastic parts affects their final shape. Click here for the archived recording.

Related Content

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Plastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

-

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

.jpg;maxWidth=300;quality=90)