Designing and Building Molds for Aerospace Requirements

The aerospace industry has some unique requirements for many of its plastic components, primarily because of the thermal expansion challenges these materials present.

The aerospace industry has some unique requirements for many of its plastic components, primarily because the polymers used for them are typically high-temperature, and glass-fiber and carbon-filled engineering thermoplastics. A supplier of molds and molded/machined components for

this industry must understand that the conventional mold design approach does not accommodate the thermal expansion challenges typically associated with these materials.

“The high temperatures required to mold many of the materials mean that normal fits, clearances and interlocking features typically found in conventional injection molds won’t work,” explains Mark Ypsilantis, vice president of marketing and sales of Westminster Tool, a Plainfield, Connecticut-based mold manufacturer with molding capabilities for mold tryouts and short production runs.

With more than a decade of history working with the aerospace industry, Westminster Tool understands the requirements for molding components in the types of materials needed to withstand the high heats in aircraft engines. Typical materials for which Westminster designs molds for aerospace customers include PEEK, PBT, LCP, PAI (Torlon), PEI (Ultem) and PPA, among others. Additionally, Westminster is a Solvay-certified processor of Torlon that understands its properties and the nuances involved in designing and building molds for this material, as well as in molding it.

“The approach to designing a mold for parts in a material like Torlon or Ultem has to be very different,” Ypsilantis says. “Keeping in mind the thermal expansion that a mold undergoes with the extremely high molding temperatures, shutoffs need to be very robust. For example, determining the thermal expansion of a mechanical action is critical to optimal mold functionality over the long term.”

Venting these tools is extremely critical, and setting them up so they can be easily cleaned is also important, because they tend to gas up and get extremely dirty, requiring more maintenance.

Gates for these molds are typically post-machined. “Not always, but definitely with some of the low-flow materials such as Torlon, we’ll machine an oversize fan gate into the part,” Ypsilantis says. “It really depends on the size of the part. If it’s a small part, you can sometimes get away with a gate that de-gates automatically.”

There are many instances in which a net shape part cannot be produced as it can with conventional thermoplastics. “There are dimensional challenges in combination with the material characteristics,” Ypsilantis explains. “In some cases, we build the mold to produce the features that are repeatable and machine the other features. We make a Torlon part for one customer in which we injection-mold a rectangular part and then machine the features.”

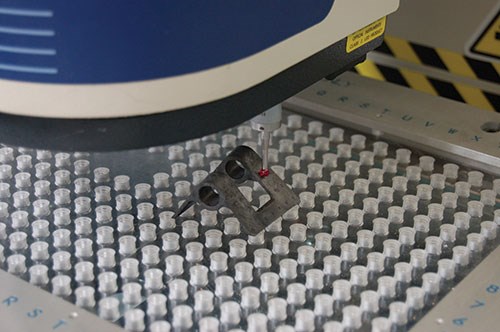

Westminster Tool has invested heavily in R&D to develop customized fixtures and tooling to machine the parts that require these added features that cannot be molded in. “We’ve taken our moldmaking competency and applied it to machining workholding fixtures, as well as developed tooling to more efficiently cut that material,” Ypsilantis says. “For example, we contend with large gates by developing customized fixturing and tooling in-house for efficient handling of these engineered, filled materials. They are very abrasive, and as we’re machining these parts, we’re creating shapes. That means we need an exact method of holding them to maintain the high quality the aerospace industry expects.”

For more information:

Westminster Tool and Westminster Solutions

860-564-6966

westminstertool.com

Related Content

Transforming Moldmaking into Digital Industrial Manufacturing

Moldmaking and digitalization is at the core of this global industrial manufacturing company’s consolidation and diversification plan.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreWomen Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)