Conversational CNC Helps Moldmaker Bridge Skills Gap

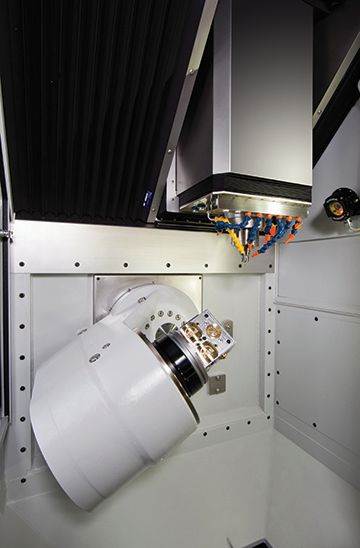

What can a company do when it has a healthy flow of work running through its facility but a lack of skilled workers to complete it all in an efficient, cost-effective manner? This moldmaker found the solution in two Hurco VMX 42i CNC mills with conversational programming capability.

What can a company do when it has a healthy flow of work running through its facility but a lack of skilled workers to complete it all in an efficient, cost-effective manner? Concept Molds in Schoolcraft, Michigan, was facing this dilemma, and while the company has 34 employees working in its 20,000-square-foot building, too many lead-man hours were being spent on time-consuming, rudimentary work. It was clear the shop needed to find a way to redirect the workload of its journeymen moldmakers so that their valuable time could be better spent. It found the solution in two Hurco VMX 42i CNC mills with conversational programming capability.

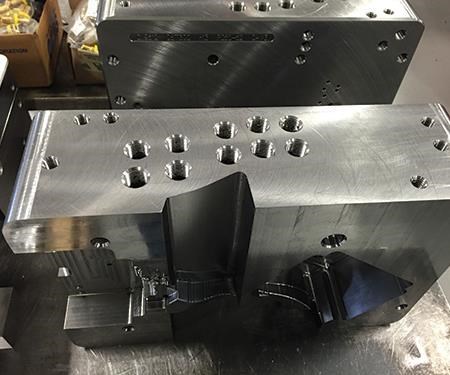

Using premium tool steels such as H-13, 420 SS, S-7, P-20, D2, high-hard beryllium and O-1, as well as some exotic materials, depending on the application, Concept Molds specializes in complex molds with such features as side actions, multi-stage ejection, multi-shot rotational molding, reel-to-reel indexing and tandem mold coinjection. The company serves the automotive, medical and industrial products industries.

Increasing Efficiency

“With building plastic injection molds, our biggest expense to overcome is labor hours, and the only way we are able to reduce labor costs is to become more efficient at what we are doing,” Jason Sparks, the company’s technical sales engineer, says. He points to the pre-heat-treat process as a specific example of a particularly time-consuming task. Before a mold can be sent for heat treatment, it must go through rough machining, drilling and tapping of waterlines and mounting bolt holes, and drilling of ejector pin clearances. Journeymen moldmakers are over-qualified but were responsible for doing the work, because apprentices at the company were not yet ready to execute the processes both skillfully and efficiently, Sparks says. The company’s efforts to hire workers with the necessary training was difficult, so other options had to be considered.

“We began to look at new CNC equipment with enhancements to the machine, such as a chip blaster and high-pressure coolant system, along with specialized tooling like drills with coolant holes and rigid tapping, and the ability to conversationally program versus having only NC programming ability,”

he says. Hurco’s VMX 42i CNC mill offered all of this and more, Sparks says, so Concept Molds purchased one—and two months later bought another one.

“The advantages of purchasing our first Hurco was noticeable immediately,” he says. “It is almost astonishing how quickly we were able to realize a return on our investment.” Pre-heat-treat drilling and tapping, and rough machining that previously took a moldmaker one week to complete could now be finished in a single day.

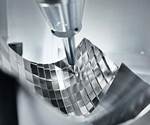

On the company’s Bridgeport machines, General Manager Josh Northrup says his moldmakers were peck-drilling holes at a feed rate of 1-5 inches per minute. Once a process for determining proper cutting tool speeds and machine feed rates was developed for the new Hurcos, holes could be drilled at 20 to 32 inches per minute without the need for a peck cycle. Additionally, Northrup says the holes are straighter, more accurate and have a better surface finish, plus they are completed in seconds rather than hours, creating a level of standardization in which the company is producing better quality in a fraction of the time. “We found advantages that we were not anticipating with the machines, such as high accuracy (within 0.0003”), repeatability for multiple setups using magnetic chucks and fixtures, and ease of programming using the built-in WinMax control software,” he says. “These are very charismatic machines.”

Northrup adds that an especially attractive feature of the Hurco is an interrupt cycle, which allows the operator to stop the machine in the middle of a program to measure the steel, change inserts on an insert cutter and clean chips out of the way, and restart the machine where it was with little time wasted.

Easy Programming

Northrup says it is important that the machines offer conversational programming as well as NC programming options because of the skill sets of some of the employees who operate them. Not

everyone has the experience required to program G codes or use CAD/CAM software, so the fact that the Hurco machines enable simpler geometries to be programmed “conversationally” has helped Concept Molds move jobs through the pre-heat-treat roughing processes much faster than previously possible, he says.

Conversational programming is a form of manual data entry, in which the programmer inputs the answers to a series of questions directly on the control panel of the CNC machine. Conversational programming on Hurco CNC machines is based on the WinMax control software platform and machinist language, a simplified NC programming language. More experienced users can merge NC programming with conversational.

“We use the conversational programming feature about 75 percent of the time, because it can only be used for programming less complex features in 2D,” Sparks says. However, the Hurco machines have dramatically reduced the shop’s costs and timing, he adds. For example, a recent job that previously would have taken 3-4 weeks to complete was able to be completed in less than two weeks. “These machines have lowered our costs anywhere from $3,000 to $9,000 per mold, depending on the size and complexity of the mold, and they have accelerated our deliveries,” he says.

At the time of this writing, the shop was in the process of completing two jobs that had required more design time than usual due to requested changes. If the shop had processed these jobs with the Bridgeports, “we’d have zero chance of delivering on time,” he says. “But because of the Hurcos, while delivery will still be tight, we should meet the challenge.”

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

Productivity Meets Precision

With machine dynamics, mechanical design and thermal stability in control, mold manufacturers can take five-axis machining to the next level.

Read MoreFeatures and Functions of Five-Axis

Capitalizing on its unique characteristics can help you fully realize the potential of five-axis machining.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)