Conquering the Quoting Challenge

Adding the right multi-CAD viewer to your quoting process helps improve customer communication, secure new business, and save time and money.

Benefits of a Multi-CAD Viewer

Name a problem that most mold manufacturers have in common. Many will answer that it is the time-intensive quoting process. A process often riddled with inaccuracies—from initial quote to quoting rework and design changes. Let’s not forget that many requests for quotes are submitted without perfect models, which further challenges profitability. In order to win more business, moldmakers need to better understand and communicate with their customers. No matter what CAD file formats you work with, adding the right multi-CAD viewer to your process can save you time and money. Following are common challenges the right CAD viewer can help you conquer head on:

Poor RFQ Response Rates

The right multi-CAD viewer can improve your response to the initial quote request. One reason is that you can actually quote the prospective customer. Many companies fail to respond to request for quotes (RFQs) in a timely manner—or maybe not even at all—because they cannot read the prospect’s CAD file format. A multi-CAD viewer will help you save time by not having to ask for a different file format than the one supplied in the initial RFQ. You’ll be prepared to receive almost any CAD file format, open it quickly to interrogate and inspect the design file.

In addition, little or no CAD experience is necessary to use a multi-CAD viewer, which means you have options as to who can respond to RFQs. You will find that you do not have to waste time recreating drawings, which is a bonus if you are only an occasional CAD user. Your designated CAD resource is also freed up to work on actual production files instead of redrawing for RFQ purposes.

Inaccurate Initial Quoting

Initial quotes can be inaccurate simply because you are rushing to meet deadlines. In your haste, you might quote too high and lose the job to cheaper bids. Rush, and you might quote too low and end up eating the cost of your mistake. Your home-grown quoting method or system could be filled with too many assumptions that you have to hope you make correctly. Guess at the assumptions incorrectly and you hurt your profit margins. You might also fail to provide value-added suggestions to improve the customer’s design or manufacturability.

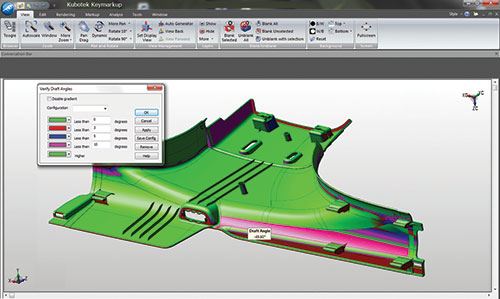

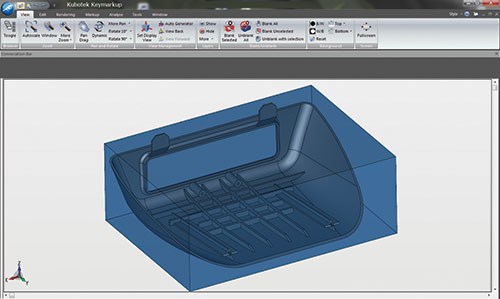

A multi-CAD viewer will help stop the inaccurate guesswork and improve your quoting accuracy. Look for a multi-CAD viewer that allows you to take detailed measurements or even gives you the option to section complex assemblies so that you can dig into hidden areas of the design.

You will be able to improve the accuracy of your quote by zeroing in on cost-sensitive areas of a customer’s part. You will also be able to submit a thorough job quote in a timely manner. Plus, a multi-CAD viewer with mark-up capabilities will give you time and a quick way to issue a quote that incorporates value-added suggestions.

Requote Rework Headaches

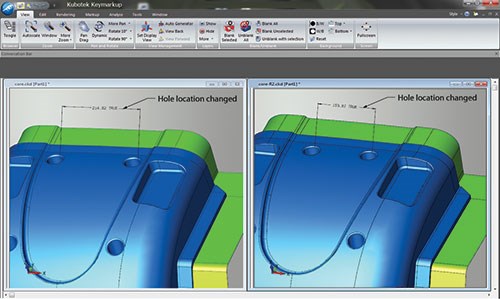

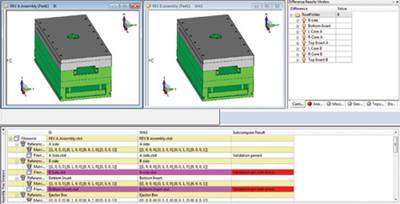

Requote rework and design changes after you’ve won a job can also be improved with the right multi-CAD viewer. Engineering change orders (ECOs) are almost always part of the mold-making process. Responding to ECOs in a timely manner, comparing and verifying data changes and implementing them into the process faster will obviously improve product quality.

Additionally, a customer-generated ECO might also result in a job requote. Using a multi-CAD viewer will ensure that you maintain, or even improve, your profitability for the work resulting from the design changes. A multi-CAD viewer will help you with the ECO process of any job by removing CAD data limitations, which means you are more agile to respond at any time during the moldmaking process.

Experienced moldmakers often add value to the customer designs. Sometimes suggesting design changes to improve manufacturability will also save time and money for both you and your customers. The right multi-CAD viewer will let you mark-up customer-issued designs to highlight the specific areas in which your expertise will improve on the customer design—using the customer-issued CAD file or even exporting in various other formats to aid in your communication.

The ease in communication will make you a mold manufacturer with whom it is easy to work. Your customer will have a clear understanding of your skills. Being able to work with customers, clearly stating and justifying value-added changes will likely improve your customer retention.

Limited New Business Opportunities

Many moldmakers today are unfortunately at the mercy of several large customer accounts. If that customer goes away, the only way to stay in business is to expand your business base. Instead of limiting potential customers to only those who use compatible CAD software, a multi-CAD viewer will allow you to branch out to customers you may not have considered.

Additionally, as a moldmaker, you put yourself in the driver’s seat of your business, responding to and working with customers that you choose. Being able to work with any CAD data means you have more control over your business flow, and are not subject to the whims of your customers.

Excessive Training Costs

With the right viewing tool, moldmakers will be able to diminish costs by reducing the need for multiple CAD packages—not to mention be able to keep costs under control for the related maintenance and training for each person using each separate CAD package.

Multi-CAD viewers will also allow files to be viewed and worked on by a non-CAD user, which will save the cost of high-priced CAD experts. You will also be able to keep your company up-to-date with all of the latest versions of CAD files just as long as the multi-CAD viewer is maintained. Simply marking up files, printing out the mark-ups to share, saving them as a PDF for easy distribution or exporting to other CAD formats will make communication between you and your customer easier. And because multi-CAD viewers can be very low cost, just winning one more due to the use of the right viewing software will make for a quick return on your investment.

Related Content

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreRead Next

Design Change Communication Modernized

A look at how CAD comparison and direct modeling technology have improved design change communication processes.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More_970x90 4.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)