Common, Global Threads in Workforce Development

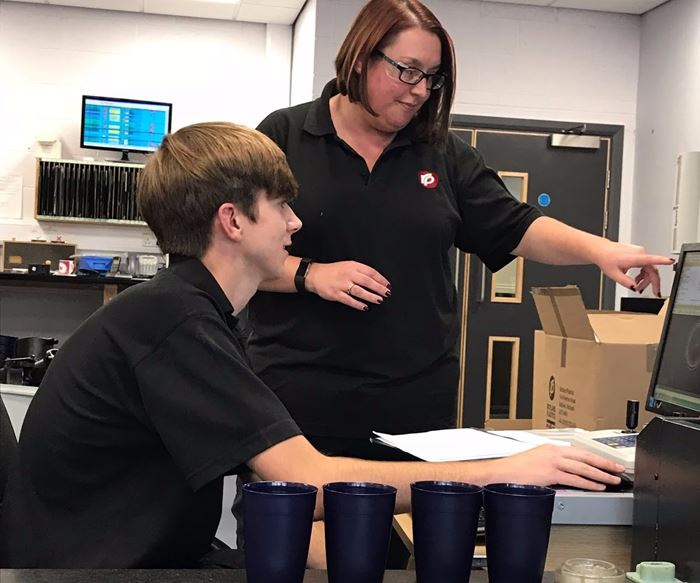

U.K.-based Rutland Plastics shares a glimpse of its five new apprentices and how it recruits and trains young talent into moldmaking careers.

Throughout 2017, I have been writing about workforce development initiatives and publishing the content either in editions of MoldMaking Technology or here, in my blog pages. You might say it’s an industry topic that’s near and dear to my heart. So, when a press release from Rutland Plastics Ltd. In the UK came into my hands announcing that five apprentices have joined the company, I found that, like North American moldmakers, UK-based moldmakers often use similar tactics when it comes to recruiting and training much-needed apprentices, and the challenges are quite similar as well.

First, a little background. Rutland Plastics is a family-owned business that was established more than 60 years ago by Ron Smart and Don Ansell. The company has over 140 employees operating out of a 66,000-square-foot facility, and specializes in the design and build of small to medium-size injection molds, prototype tooling, injection molding (for production and sampling) and other value-added services.

Saria Monsen-Elvik provided the press release and additional information about Rutland’s apprenticeship program and recruitment strategy, saying that there is a national trend that has seen a decline in apprenticeship enrollment. “On average, we now get roughly a dozen or so applications (we are rural based which affects the numbers). The decline sadly mirrors the national trend that has seen a dip in apprenticeship enrolment.” U.S. moldmakers can relate, having faced this problem for many years now.

Monsen-Elvik says Rutland had a higher number of openings in different departments this year. The company begins its recruitment process by advertising annually on the national government website gov.uk, which is a very user-friendly website. Searching for jobs or apprenticeships is a snap. I asked Monsen-Elvik what qualities help determine whether a candidate is qualified. “Enthusiasm, and it helps if they have a related interest in some capacity,” she says. “It is no surprise that most of our apprentices, past and present, are car enthusiasts, particularly on mechanics side! They do need to possess at least three General Certificate of Secondary Education (GCSE) qualifications, of which one needs to be maths or a science subject. They also need to complete an aptitude test that we have devised.”

Making it through the recruitment process were Xavier Straight-Garten, 21, Isaac Topley, 19, Lewis Still, 21, and Craig Redfern, 16. Most recently, Rutland has taken on another promising apprentice in Aaron Bateman, who is 18. “Aaron comes to us with a degree of knowledge, having studied a two-year engineering course at Peterborough Regional College,” she says.

“The training program at Rutland can last between two and three years, depending on the area within the business they have secured a position,” Monsen-Elvik says. “The first year comprises a twelve-month rotation throughout the business, across all departments. For instance, an apprentice may spend a month learning in our quality assurance department, or in the mould shop shadowing a tool setter or in general maintenance. After completing their first twelve months gaining exposure to all departments they can then apply to a department of their own choosing, should a position be available.” She adds that, during their training, they also attend college a day or two each week to add a technical qualification to their practical training. Again, this is very much like our North American training experience, as illustrated in our current workforce development article titled Moldmakers Choose Different Pathways to Workforce Development and also in my feature about suppliers to the moldmaking industry, titled Supplier-Based Training Programs Fuel Mold Industry Needs.

Craig Redfern, at 16 the youngest apprentice, is beginning his new role as Trainee Tool Technician. Speaking about the company’s apprenticeship scheme, he says, “It has opened up a whole new world, very different to school. This year has given me a huge amount of confidence. Besides the technical skills I have learned, the most valuable have been people skills, particularly in communication.”

Lewis Still says he is pleased with landing a position in the Quality Assurance Department at Rutland. According to Monsen-Elvik, when he left school, he worked briefly as a machine operator. Now, with the chance to learn a profession, his intentions are to become an extremely qualified member of the team.

Joining Rutland’s production technicians are apprentices Xavier Straight-Garten and Isaac Topley. Both knew they wanted an alternative to university, a path that most of their friends took. Xavier and Isaac agreed “that finding a career path early, learning new skills and being paid could not be better.” Yep, I think we’ve all heard similar feedback from apprentices throughout North America.

“I believe apprenticeships are vital for our industry, as well as being an integral part of our future planning,” Monsen-Elvik says. “I am delighted to report that all our apprentices have established themselves as important members to the departmental teams they have joined.”

Related Content

2021 30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)