Childhood Memories of My Dad’s Mold Shop

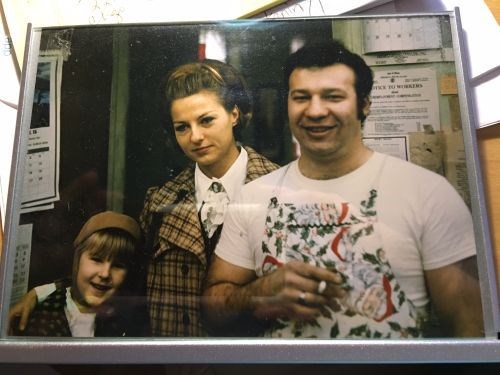

Get a load of the young girl in the photo here. Yep, it’s yours truly at about six years old, visiting my dad’s shop with my mom during the holiday season of 1970.

MoldMaking Technology's senior editor, Cynthia Kustush, with mom, visiting dad's moldmaking shop in November of 1970.

Get a load of the young girl in the photo here. Yep, it’s yours truly at about six years old, visiting my dad’s shop with my mom during the holidays in 1970. Note the festive work apron my dad’s wearing – with mom’s help, he made one for each employee at B A Die Mold, and I remember seeing the guys wearing them and thinking how neat that was. They actually wore them for several Christmas seasons, according to my dad.

At that time my dad’s company was younger than I was, having been established in 1968, but it was growing and, already, had moved into its first stand-alone building in Downers Grove, Illinois. The building still exists, and any time I happen to drive past it I think how much things have changed and how the business has evolved – and how it influenced me as I grew up. I know many second-generation mold builders probably have similar memories from their families’ mold shops. (I’d love to hear some stories, if you’d care to share!)

My father worked so many hours when I was young. He had to if he was going to succeed. I would be overjoyed if I was still awake to see him come home in the evenings. Most of the time it would be me, mom and our German Shorthaired Pointer, Koko, at home while dad worked late (I was an only child until the age of eight). He still works a lot of hours, actually, but he loves what he does – as so many moldmakers do.

Even at age six, as now, I was fascinated by the machinery in my dad’s shop. I loved the smell of cutting fluids and the crunch-like sound of the steel chips on the floor when I stepped on them. I remember occasionally prying chips out of the bottoms of my dad’s work shoes, too, when I would busily polish them up for him. Of course nowadays you don’t find chips littering the floors like you did then. Shops are so very clean now by comparison – and that’s not to say they were very dirty before, but you can seemingly eat off of some shop floors that I’ve seen recently.

I fondly recall my dad bringing poster boards and markers home and asking me to create safety posters for the Downers Grove shop. That made me feel happy because I was helping remind him and his guys to wear their safety glasses in the shop. I know I made more than one sign, but the safety glasses poster stands out for some reason. Every time I visited the shop after that I’d see my posters and feel proud. I remember also observing a few “girlie” posters here and there, but I won’t go into that… My how times have changed!

As the years passed I spent more time at my dad’s shop, usually during summer break helping in the office, but the company had quickly outgrown the Downers Grove building and newer, more advanced machinery was purchased and more skilled employees hired to better serve customers. That, I’m happy to say, hasn’t changed. Even with the ups and downs that challenged our industry over the last 16 years, the goal to add equipment and capabilities that speed mold building and optimize quality never ceases. And that, I know, will never change.

Speaking of speeding mold building, I’d like to let everyone know that MMT is already seeking entries for our 2017 Leadtime Leader Awards. The deadline for submitting the initial entry form, which you can access here, is November 1. It only takes a few minutes to complete, and if your company is accepted you’ll get a more comprehensive form to fill out. I’m kind of hoping my dad’s shop will enter (hint, hint, dad).

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More_970x90 1.png;maxWidth=970;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_970x250 1.png;maxWidth=970;quality=90)