Chicago Mold Engineering: In The Spotlight

Focusing on a niche in the automotive headlap reflector market—coupled with the most advanced technologies and mold manufacturing techniques—lights the way for this moldmaker’s 2007 Leadtime Leader Award: Large Shop.

#automotive #leadtimeleader #casestudy

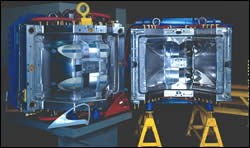

While Chicago Mold Engineering Co., Inc. (CME, St. Charles, IL) has manufactured plastic injection and compression molds for the thermoset and thermoplastic industries for the past 62 years, the company’s decision to specialize in multi-cavity thermoset injection molds for automotive headlamp reflectors has thrust them into the spotlight as an industry leader in these types of molds. That—along with their unwavering commitment to quality and customer service—provides their customers with consistently superior molds for their parts.

The company’s $10 million average in annual sales and an average sales growth of 10 percent over the past three years is a testament to their ability to design and build a wide range of types and sizes of molds in addition to their specialty. However, it is these tight-tolerance molds that contain all of the optics for the headlamp that have contributed significantly to the company’s growth, notes CME President Dick Laverty. Additionally, the company is well equipped to produce compression, stack and multi-color/multi-shot molds—whether they are small multi-cavity with complex side actions or large (up to 80,000 lbs.) single cavity production molds.

Featured Content

And, the company is not afraid to take risks by investing in the latest equipment to get the job done. They purchased a white light scanning system that no other moldmaker in the U.S. has for real-time inspection capabilities and reverse engineering (see "Taking Technology to New Heights", November 2006, page 40). “In order for us to continue to move forward with this type of technology, we have to look to the future for what type of work we will be doing and then budget equipment purchases to meet those needs,” Laverty notes. “CME continually explores technological advancements through independent research based on customer requirements, and also through staff recommendations developed during training or educational opportunities. Quarterly meetings held with the CEO, CFO and President determine how much can be budgeted for the following half year, year and next three years based on reports from the sales department and the industry in general. They seek the advice of their Board of Directors—which includes a bank president—who, along with the CFO who has an MBA, gives advice regarding the affordability of the desired capital purchases.”

A Family Concern

Founded by Eric W. Oswald in 1944 with just $500 and a dream, CME has built a legacy over the past 62 years. Oswald was born in Berlin, Germany—where at the age of 14—he began his tool and die apprenticeship. Attending night classes at the Gauss School (sponsored by Siemens), he studied English and trade-related subjects. Sponsored by a family friend, Oswald left Germany in 1928 at the age of 26 and immigrated to the United States.

Oswald settled in Detroit and entered the employ of the Ford Motor Company, subsequently working for the Packard Motor Company. He next moved to Chicago and went to work at Western Electric as a tool and die maker. He held similar positions in the area before spending two years working at Caterpillar (Peoria, IL). In 1936 he partnered with two friends to start the Panos Manufacturing Company. The partnership dissolved two years later in 1938.

Then, Oswald worked for Sinko Manufacturing in Chicago through the war years, until being offered and declining a partnership in 1944. At that point, Oswald decided the time had come to own his own business. CME’s first plant was in Chicago on Walnut and Hoyne—on the second floor of a rented building. A fire destroyed the building in 1947 and CME was forced to move. The second plant was once again in Chicago on Wood Street and Chicago Avenue. They soon outgrew that building and in 1952 the third plant was custom built in Hillside, IL.

As the company continued to grow, Oswald’s sons Erik and Ralph joined the company in sales and production respectively. In 1985, CME’s current home was built on four acres of land in St. Charles, IL. Today, company headquarters spans 40,000 square feet with 55 employees. In 2002, Ralph assumed the helm as CEO and Chairman of the Board and has been credited as the driving force behind the continual improvement policy of CME, maintaining a state-of-the-art facility with the latest equipment and software. Once again, a new generation of Oswald leadership is in the making with the addition of Ralph’s son Jeff to the executive management team. Plans for a plant expansion are under consideration.

Triumphing with Technology

According to Laverty, the company’s closest competition comes from medium to large mold builders who manufacture complex 3-D molds with multiple side actions. “We have always been proactive in leading the industry in technological advancements,” he states. “In order to stay competitive, we utilize the latest technologies available—like high-speed machining and carbon cutting, wire EDM, white light scanning, reverse engineering and unattended machining. CME’s production is supported by high-speed, five-axis machining centers, standard and wire EDM equipment, five-axis graphite milling centers, and robotic work changers—all using the most current CAD/CAM software.”

Laverty explains how all of these technologies have proven critical to overall production speed and reducing costs in CME’s mold building process. “The high-speed, multi-axis machining centers are faster and have greater detail capabilities, producing finishes so fine that further hand work is often not required,” he states. “In one instance, cutting was done at 15,000 rpm, feedrate of 260”/minute with a 1/8” ball-tip with a stepover of .0035” for roughing, followed by finish cutting at 18,000 rpm, feedrate of 200”/minute with a 1/16” ball-tip with a stepover of .0025”. This process created a decorative ceiling tile with greater pattern definition—at one third of the time required by the former sand-casting process.

“With the help of Makino and System 3R, we have set up a work cell which includes a robotically controlled, high-speed, five-axis graphite mill which is coupled with two EDM machines so that electrodes can be produced, verified for accuracy and then moved robotically to the EDM machines for burning the details into the cores or cavities automatically—with no one attending the machine,” Laverty continues. “This speeds up the entire graphite milling and EDM process to help in maintaining the schedule for each mold we build. This has been particularly effective in building the reflector molds with multi-faceted surfaces to create the highly complex optic prescriptions. Up to 30 electrodes can be manufactured to burn just one reflector insert.”

The ATOS III white light scanning capabilities make the inspection process many times faster than the time-consuming CMM checks that were previously used for all inspections on the optic inserts for the reflector molds. “Additionally, with the reverse engineering capabilities of the ATOS III system, we can create 3-D databases for molds that have been built elsewhere so that we can provide our customers with a database should anything get damaged or broken in the molds once they go into production,” Laverty comments.

Maintaining Leadtimes

In today’s competitive times, leadtimes are everything, and CME once again rises to the occasion. Laverty says the company’s leadtimes depend upon the size and complexity of the tool. “Whether it is a small prototype we complete in two weeks, or a 7-foot spa floor mold completed in 16 weeks, it is given the same level of priority and attention throughout the mold build,” Laverty explains. “When we do prototyping, we are sometimes working from a handmade piece that has the general shape of the part but no true dimensional detail to it. We will take that part, photogrammetize it to get the basic 3-D model and then ‘massage’ it in the computer to create the detailed database necessary to produce the prototype part. This process may only take a day or two utilizing the ATOS III system as opposed to producing a database with nothing to start with other than the actual part. The ATOS system has been a tremendous advancement to shortening our leadtimes for prototyping. When we do the larger production molds, it is a more time-consuming process since you have to go through more steps in the preliminary design stage and the approval stages of the mold build.

“As an example, a two-cavity thermoset injection mold for a Ford reflector was produced in 14 weeks,” Laverty continues. “It included hardened cavity inserts and a two-drop cold runner manifold system. The preliminary design and approval stage of this mold took four to five weeks, so in actuality the mold was built in 11 weeks. This tool weighed 6,500 lbs.”

Another example is a two-color, rotating platen mold CME built for the Buick Rendezvous taillight. “This was a very large, complex mold which had an internal retractor mechanism built into the mold,” Laverty recalls. “Once the preliminary design and approval stage was completed and steel was received, this tool was completed and sampled in just 12 weeks. The spa floor tool mentioned above weighed more than 30,000 lbs. A smaller mold weighing in the range of 12,500 lbs. was completed and sampled in 10 weeks. Less complicated production molds without mechanical features (side actions or lifters) can and have been completed with a three to four week leadtime. Our continual goal is to produce the highest quality mold for our customer in the shortest time possible.”

From Art to Part

Laverty notes that maintaining these stringent leadtimes is only possible with cooperation company-wide. “It begins in our program management department where a detailed estimate is developed,” he says. “Once we are awarded the project, the estimate is reviewed, updated and entered into our computerized program management system. Our program management system is a custom software system that we developed with the help of an outside consulting and programming company. This system gives us the ability to schedule the work through our plant, estimate the backlog in each department and also provide us with an ongoing cost status as the job progresses through the various stages of engineering and production. The actual estimate is placed into the system of active jobs and all hours quoted are assigned to the specific departments for shop load scheduling.”

The job then enters CME’s engineering department, where all molds are designed in solids using Unigraphics (UG-NX) MoldWizard. “The mold is really a complete tool before it leaves the engineering department,” Laverty notes. “We review the design before, during and as the engineering is completed both internally and with our customer. With the initial layouts, we will generally visit the customer and go over the preliminary design to receive approval to purchase steel and to get the customer’s input as to any changes they would like on the initial preliminary design. Or if preferred, we can provide preliminary designs electronically to the customer for their review and approval. Our data transfer system offers a variety of options to our customers—including our FTP site, various Internet, Extranet, FTP and AutoWeb venues set up by our customers, and e-mail if file size allows.”

With customer approval, CME orders the steel and updates the design with any changes requested by the customer. After the design is completed, the company holds a final review with the customer to ensure everyone is satisfied with the design and there are no other additions or changes that the customer would like.

As the project progresses through the final design phase a management review meeting is held with the moldmaker, production manager and project manager to review the final design and to update the progress on the project. This is where all specifics regarding the tool are discussed along with the first sample date being set. “Once a job is in the plant, its status is reviewed each day,” Laverty states. “We have a meeting each morning to discuss any changes to deliveries and any updates of information on current jobs. This meeting is attended by the CEO, President, Executive Vice-President, Engineering Manager, Production Manager, Sales Manager and all of the Project Managers. This is a brief meeting where everyone has the chance to give an update on their specific jobs.”

CME also holds a weekly “Tool Meeting” every Monday afternoon where they go over each active job in more detail so that everyone is aware of the status on each job—reviewing and revising scheduling issues in order to meet or beat the completion date. Here, everyone is given an updated Job Status Sheet at the weekly tool meeting showing the percent of completion for the design phase of the job and noting any changes to the delivery date.

CME also updates its customers on a weekly or bi-weekly basis with progress reports supplied by the project managers. Throughout the entire mold build, the tool is checked and re-checked using one of many inspection systems. Depending on the location of the mold components and complexity of the inspections required as the job progresses CME will use either the ATOS III System, CMM inspection or the Faro Arm for this inspection process. “Once the mold is near completion, we schedule a sample and contact the client to discuss when and where the sample will take place,” Laverty adds. “We enjoy a 100 percent success rate for on-time delivery and customer satisfaction.”

Mold Manufacturing Advances

CME has extensively automated mold manufacturing from the initial roughing of blocks, through high-speed, multi-axis machining being done to near finish levels, the manufacturing of detailed electrodes for EDM applications, and the ability to produce accurate inspections and validations of the molds produced. “Nearly 10 years ago we installed CNC EDM die sinkers with toolchangers for 24/7 EDM work,” Laverty recalls. “The 1999 addition of the SNC64 Makino graphite mill with System 3R robot and electrode carousel added the capability to machine graphite electrodes 24/7. Our latest automated cell incorporates a 5-axis V56 Makino graphite mill with System 3R robot, electrode carousel, electrode rack and two Makino EDNC65 die sinkers for round-the-clock graphite milling and burning. Installed in the fall of 2005, this work cell can machine electrodes and place them into the die sinkers for burning.”

Also paramount to the company’s success is the aforementioned ATOS III white light scanning system. “It enables us to provide a wide range of services—from reverse engineering to mold inspections and validations,” Laverty emphasizes. “In one case, natural textures were replicated for mold finishes with the ATOS system. This created a timely solution to one molder’s requirements by cutting both time and costs. Molders seeking comparative analyses of parts, or material performance have benefited tremendously from the fast and highly accurate capabilities of the ATOS III system.

“This system is the most advanced in the world,” Laverty continues. “We can reverse engineer anything. Whenever a client has a problem with a tool, and does not have files, we can scan the tool and prepare the files necessary to repair or modify the mold. There are other systems, but none as accurate at the ATOS III. It is being used by NASA and at Los Alamos.”

Laverty feels that unattended machining capabilities combined with automated technology on the plant floor help the shop manage today’s labor issues and enhances the abilities of the staff. “CME has maintained very low attrition rates over the years,” he notes. “I have worked at CME for 40 years and there are still three employees who have more seniority than I have. This highlights the proven teamwork at the core of CME’s successful labor management—which translates into hundreds of years of skilled craftsmanship experience under one roof. When we hire people to work at CME we tell them that we hire for the long haul and not for the short term when we happen to be busy. If we feel the need to put on additional employees, they are assured that they will have long-term employment as long as they commit to becoming a team player with the goal of continually meeting our customers’ expectations.”

Global Strategies

Fortunately, competition from abroad has not significantly impacted CME’s business as it has other moldmakers who serve the automotive industry. “Globalization helps keep you on your toes investigating new technology and faster ways to build a mold,” Ralph Oswald states. “We practice lean manufacturing and cross-train personnel to become increasingly more efficient.”

Challenges the company has seen develop with increased globalization include the automotive industry’s Tier One payment term extensions and the foreign dollar exchange rates’ effect on customers choosing to place their work in Canada, Mexico, Portugal or China. “The payment term problems illustrate the interdependency and multi-level impact aspects on the industry,” Oswald explains. “Globalization has made us work harder to succeed with the challenge to produce a better product faster and less expensively, continually improving our efficiency in producing top quality molds. As an American shop, we will continue to emphasize our worker’s rights and to provide a safe work environment. We see our quality workforce as essential to maintaining our leadership in the industry globally.”

Globalization has caused CME to seek diversity in their customer base as well. “We understand the economic pressures that cause customers to seek the best price and we make every effort to be competitive,” Oswald notes. “Globalization also has provided us with great opportunities to perform repair work for customers having foreign-built tooling, and to supply them with accurate CAD data on those molds prior to their use so that any repair, change or maintenance can be carried out locally—reducing their downtime.”

Marketing Strategies

Behind such a successful mold shop is a solid marketing plan. “We know the difference in finding and keeping clients in our world marketplace,” states Sales Manager Don Mazurek. “Our goal has always been to build only high quality tools for our customers. This will continue to be the basis of our marketing strategy, and integral to that will be our continuing ability to service our customers better than anyone else in the industry. To facilitate this level of service, we hope to work more closely with part designers from the lighting manufacturers and other industry representatives. We have learned that our input before the molds have been built can shorten leadtimes and enhance the success of projects for everyone involved.”

CME’s short-term marketing plan centers on their niche of thermoset molds for parts replacing traditional metal parts and enhanced automotive lighting molds. “Beyond periodically updating our printed brochures to inform existing and potential clients of our capabilities, we have been engaged in more trade show and conference attendance and participation,” Mazurek says. “At NPE 2006, we had the opportunity to share booth space with Bulk Molding Compounds, Inc. (BMCI, a polyester molding compounds manufacturer) as their representative thermoset mold builder, in conjunction with a materials manufacturer and a thermoset molder. Additionally, we had a booth at the Part 2 Design Show as well as at the SPE Thermoset Division Conference, at which we also were guest speakers.”

CME also presented at the ITB Group Conference on Automotive Front End Modules where they discussed thermoset reflector molds along with inspection techniques for automotive lighting. “We have been honored to serve as presenters for the past two years at the Joy of BMC training seminars hosted by BMCI,” Mazurek comments. “We have had papers and articles published this year related to our ATOS III system and mold building techniques. We plan on doing more similar presentations regarding our lighting expertise in the coming year.”

Leading the Competition

CME will continue to investigate new technological advancements and update production equipment and software as needed to stay ahead of the competition, Laverty maintains. He cites the following measures can be “combined for impressive growth in our capacity and output.”

- Updating and replacing production equipment with a trend toward smaller footprints of machinery for greater efficiency in space utilization.

- Implementation of robotics with a broader range of equipment to expand automation and adding a new System 3R robot to the Makino 85W EDM for changing larger electrodes.

- An additional ATOS scanner to be implemented with the existing EDM cell to complement the current capability with scanning the electrodes for accuracy. This will provide 100 percent inspection of electrodes prior to the placement of the electrodes in the correct location for burning in the EDM (all in an unattended environment).

“CME has the ability to produce any type of mold—injection, compression, stack, thermoplastic or thermoset,” Laverty states. “When presented with a new mold concept, we take pride in developing a solution to meet that customer’s requirements. More than 60 years of meeting those challenges means that CME has a cross-section of skilled personnel encompassing a wide range of experience for every type of mold and stage of mold building.”

RELATED CONTENT

-

Laser Texturing Proves Automotive Potential

A cosmetic interior tooling application in North America could spell a brighter future for a process that promises savings throughout the supply chain.

-

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

-

Thermoset Mold Builder Takes on EV Market

New Dynamics and NDC International provide complete tooling and molding solutions for the electric vehicle market and electronic encapsulation technology.

_970x90 4.png;maxWidth=970;quality=90)

.jpg;maxWidth=970;quality=90)