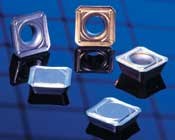

Cermets: A Machinist's Tooling Solution

Less expensive than coated carbides, and equipped with a long tool life, cermets provide a cost-efficient solution to many machining applications

Since the 1920s, cermets have been an integral part of the metalworking industry. However, in the past few years they have enjoyed a surge in popularity, thanks to new technology, which has expanded possible cermet applications. Traditionally used just for semifinishing to finishing operations, newer cermets have increased toughness that makes them comparable to some carbides, while their good shock resistance promotes good performance for some interrupted cuts. Origins

The word cermet is derived from the terms ceramic and metal. A cermet is a hard material based on titanium carbide or titanium carbonitride cemented with a metal binder. The first series of cermets developed in the late 1920s were based on titanium carbide/molybdenum carbide with a nickel binder, and were characterized by low bending strength and high brittleness. However, in the 1960s improvements were made with the addition of molybdenum to the binder.

This increased cermet toughness. A few years later, the addition of metal carbonitrides contributed to improved wear resistance, thermal shock resistance and decreased plastic deformation. In 2003, new micrograin cermet grades were introduced, including a PVD-coated super micrograin cermet whose coating provides greater thermal stability and the ability to handle higher cutting speeds. The micrograin structure of these cermets contributes to a doubling in the bending strength, while the fracture toughness remains comparable to other cermets. This new generation of cermets also is capable of handling interrupted cutting operations that before weren't feasible.

Characteristics

Characteristics of cermets include high wear resistance, low reactivity with most workpieces and long tool life. They produce excellent surface finishes, and maintain tight tolerances over their life span. Higher cutting speeds may be used with cermets, especially for semifinishing to finishing operations, because of their high wear resistance.

High Wear Resistance

Cermets' high wear resistance is contributed in part by their high hot hardness, which is greater than most cemented carbides. Cermets also feature low reactivity, as they are more chemically inert than tungsten carbide. The low affinity to the workpiece means that edge buildup and cratering are not significant for cermets, as with carbides.

Bending Strength

Bending strength is determined by subjecting a material sample to an increasing load until failure. Traditional cermets tend to have a lower bending strength than carbides. To prevent cermet breakage, feedrates are usually lowered. However, the new generation of micrograin cermets features bending strength equal to that of carbide, and twice that of other cermets. Therefore, machining efficiency is improved as the feedrate is increased.

Thermal Shock Resistance

Thermal shock resistance is important to consider when choosing a cermet, especially if interrupted cuts and coolant are aspects of the machining process. Cermets tend to be more shock resistant than ceramics, but less so than carbides. In the past, coolant was recommended only when grooving, threading or finish turning, and then only with coated cermets. The newer micrograin cermets have much better thermal shock resistance than previous cermets, thereby allowing the use of coolant when necessary for a wide range of applications.

It is not mandatory to use coolant when machining with cermets; however, coolant is generally applied for three reasons: cooling, lubrication and chip evacuation. Due to their good wear resistance, welding resistance and high hot hardness, cermets provide excellent surface finishes even when dry machining. In addition, numerous different chipbreakers promote smooth chip evacuation without the use of coolant. Chipbreakers are the molded or ground patterns on an insert that break up the chips formed by the machining process into manageable pieces. Long chips can damage the workpiece, or be dangerous to the operator.

Applications

Traditionally, ideal applications for cermets have included finishing and semifinishing at higher speeds, lower feeds and cutting depths. Although turning on CNC lathes is the most common cermet application, Swiss-type machining is also ideal for cermets, since they hold their size and maintain tight tolerances.

Grooving and threading applications also are compatible. Cermets also may be considered for finishing milling operations, and they offer better finishes and dimensional control than carbides. Significant tool cost reduction may be achieved when milling with cermets as they can run at higher cutting speeds than carbides, and their tool life is longer. In some cases, they can eliminate grinding or polishing operations. In addition, the new generation of micrograin cermets can also handle interrupted cuts when turning due to their superior toughness. When specifically pertaining to the mold industry, cermets are used in milling molds and dies for applications like vehicle transmission pieces, brake drums and rotors, rear differential housing, body panel molds, etc.

A Valuable Solution

Cermets are best for machining steels, cast irons, cast steels and aluminum. Their resistance to edge buildup allows them to be used for certain high-speed machining operations such as the ones listed previously. They also are not prone to flank and crater wear and the newer grades work in some 300 or 400 series mild stainless steels.

In today's cost conscious moldmaking industry, cermets have proved to be a valuable addition to the machinist's tooling selection.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreRead Next

Selecting a Carbide End Mill for Aluminum Applications

Specific geometries and characteristics of a carbide end mill are required for efficient machining of aluminum.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)