Precision Mold and Machining Services Inc. (Warren, Michigan) offers a variety of services to the mold industry, including gun drilling, EDM machining, engineering changes, mold repair and maintenance, and three- and five-axis CNC machining and boring. For more than 30 years, the company has accepted overflow work from mold manufacturing customers and strives to deliver superior quality work and fast turnaround times because they know lead times are critical.

The company is also ISO 9001:2015 certified (soon to be AS9100d certified, Q3 2019), underscoring its focus on high quality in every process it performs. For five-axis machining, Precision Mold currently runs two DMG MORI DMU 85 monoBLOCK series CNC machines, which feature a 33.5-inch table diameter and X, Y, Z travels of 36.8 by 33.5 by 25.6 inches. The company also has two DMG MORI 210 P duoBLOCK series CNC machines, featuring a table diameter of 66.9 inches and X, Y, Z travels of 82.7 by 82.7 by 49.2 inches. “We have always invested in high-end machine tools so that we can complete work quickly and with extreme accuracy,” Brandon Loehr, machining manager, explains. Both Loehr and his brother Taylor, business development engineer, work with their father, David, whom owns Precision Mold.

Featured Content

If a process is not producing results at an acceptable level or rate, Precision Mold finds a better way. For example, in 2013 the company changed its CAM software to hyperMILL from OPEN MIND Technologies USA (Needham, Massachusetts) and in so doing, significantly changed the face of its five-axis CNC milling operations and its overall business, for the better.

Optimized Tool Paths Boost Cutting Speeds

“When we purchased our first five-axis machine in 2013, we quickly realized the limitations of the software we were using at the time,” Brandon explains. “While we were able to create five-axis simultaneous tool paths, the tool paths produced resulted in excessive and jerky movements of the B and C axes.” For example, the old software, when performing automatic, five-axis simultaneous tool paths, would send the rotary C-axis spinning all over the place, according to Loehr. “Then the cutting tools basically followed it all around, too. It looked fast and cool, but it was inefficient. It was fast on the calculation side, but it was not creating a smooth tool path. You might have programmed for 150 inches a minute, but it only moved 30 inches a minute if it was moving all the axes around simultaneously.”

If a process is not producing results at an acceptable level or rate, Precision Mold finds a better way.

As a result of the previous CAM software’s performance, Taylor Loehr says he had to spend a lot more time creating multiple 3+2 tool paths to more quickly achieve the results that customers required. “This led us to search for a more efficient CAM solution,” he says. A few years after purchasing the first five-axis machine, they turned to their machine tool supplier representative for recommendations on the best software options and that is how they learned about hyperMILL CAM software for seamless and precise programming of 2.5D, 3D, five-axis milling and mill/turn tasks, and the hyperMILL MAXX Machining performance package for maximizing machine performance.

Five-Axis Capabilities, Finishing & More

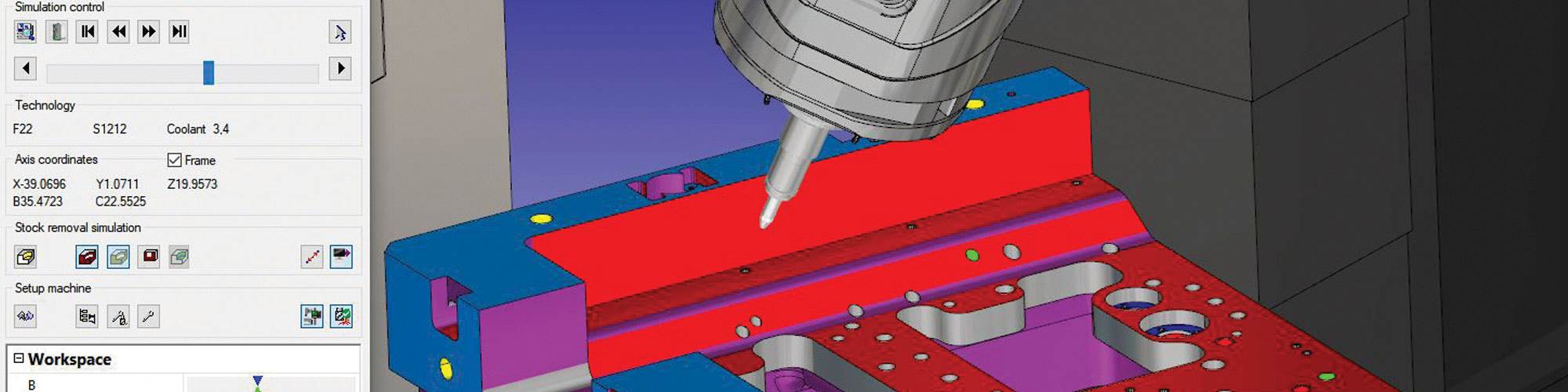

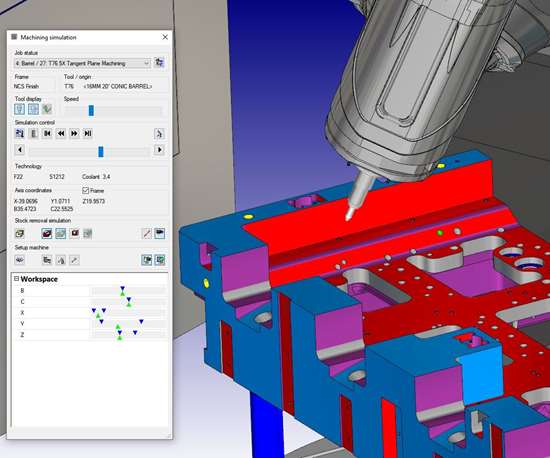

hyperMILL MAXX Machining is a corresponding CAM package with modules for high-speed milling, drilling, roughing and finishing, the tool paths of which are extremely easy to program, according to the Loehr's. The hyperMILL MAXX Machining finishing module makes efficient use of machine and cutter options in relation to surface quality and speed, by applying an innovative 5-axis tangent plane machining strategy and conical barrel cutters (specifically the Emuge Circle Segment end mills, which they learned about at the same time they discovered hyperMILL) that use the functions of a barrel cutter as well as a ball endmill within the same cutter.

"Previously, we would have to either extend our tools or spend extra time programming to produce the same result. Our programming time was cut in half due to not having to create dozens of similar tool paths with different tilt angles,” Taylor says. "Additionally, this allows us to finish more areas with a single, short tool because we are confident that the five-axis movements will produce a finish that is up to our standards."

Regarding the cutter style that the Loehr's are now using, Alan Levine, managing director of Open Mind Technologies, says the radius of a conical barrel-style cutter is much greater than that of a standard ball nose cutter whose radius is defined by the cutter’s diameter, and this simple change in cutter style enables a large step-down and has made a notable difference in the overall finishing process. In addition to time reduction, a better surface finish and a more accurate surface geometry is achieved.

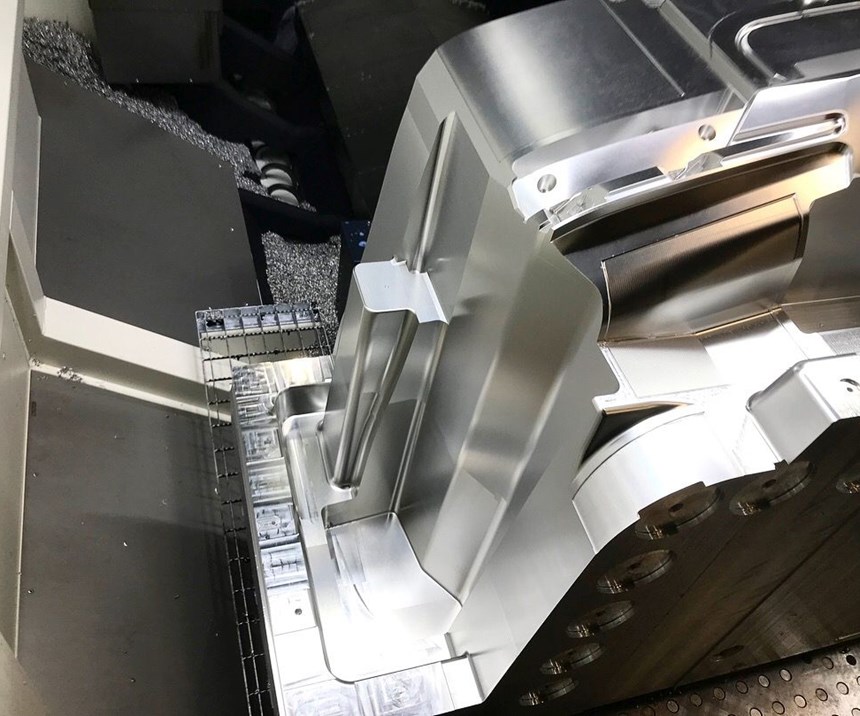

“We machine some very large blocks with a lot of details, so by using hyperMILL MAXX tangent machining and tangent plane machining strategies with conical barrel cutters, we are saving 10-15 machining hours per mold versus the time it takes using the current industry standard Z-level strategy with ball-nose cutters,” Taylor says. “We used to machine pocket walls with a ball and bullnose end mill using a 0.010 inch step-down. By using a conical barrel cutter with hyperMILL MAXX Machining, they can now take a step-down of 0.150 inch," Taylor says.

It is a more controlled process.

Automatic Indexing

hyperMILL has an automatic indexing feature, which controls the movements of the axes to make a more efficient tool path. It seeks to take regions of 5-axis command positions and simplify them with 3+2 motion, also with full collision checking. "It lets the cutter do its work without moving the machine all around and gives us a more accurate cut. It does this seamlessly and without excess movement of the machine axes," Brandon says. The auto indexing function automatically finds the best tilted solution and only uses simultaneous movements where necessary. “It is a more controlled process. It won't retract the cutter. Instead, it will make circular movements to go directly to the next spot and continue the cutting as quickly as possible, which reduces a lot of the excess movement we were getting with our other software, especially when machining corners,” he says. “As a result, it is faster and can keep up with the feed rate that is programmed. There are fewer moving parts, too, so it is easier to get up to speed.”

Collision Avoidance

“If a potential collision is detected, the automatic pitch adjustment function in hyperMILL will change the contact point of the cutting tool to finish the desired machining area entirely,” Taylor explains. As a result, programming time is reduced (less tool paths to calculate) and the surface finish quality is not affected negatively.

Our programming time was cut in half.

Control and Accuracy Brings Finer Finishes

“With hyperMILL, we can achieve excellent surface finishes due to the smooth and limited movement of the rotary axes,” Taylor says. “When using our old software, gouged or bumpy surfaces in the tool paths would have to be benched out and re-machined. Our goal is to have zero need for spotting, and we are pretty close to achieving that when we machine both cavities and cores because of hyperMILL.”

He says the company uses hyperMILL’s automated probing function to quickly and easily inspect workpieces before they come off the CNC. If any deviations are detected after finish machining, probing cycles, which are integrated in the machining process, will enable the machine to adapt its program to address the issue. “We use the probing tool for everything we cut to ensure it matches the specifications of the customer, which saves us a lot of time and expense.”

Our goal is to have zero need for spotting, and we are pretty close to achieving that when we machine both cavities and cores because of hyperMILL.

“The key point is to do a quick inspection prior to removing the part from the machine,” Levine says. “For example, if a missed region, due to a broken cutter or a large deflection, is detected first on a coordinate measuring machine, then the part is already moved away from the CNC machine, and likely the next part is already being cut. Identifying possible problems while still on the milling machine reduces risk and simplifies the workflow.” He notes that the on-machine probing is not generally a substitute for final inspection, but it gives the shop assurance before taking a large block off a milling machine. “Also, if they take it off the mill and later remount, alignment will be problematic no matter how good the setup routine,” Levine says.

More Speed and Control Boosts Output

“It's very easy to keep up with the machine and keep operations running, whereas before, it was frustrating because we would run out of time during the day trying to get the programming done,” Taylor says. “With the old software, we might have to calculate a single tool path two or three times until we achieved a decent one to run. Some longer tool paths might take half an hour to calculate, but if you have to redo it three times, you just wasted over an hour.”

“We can take on more jobs and complete them faster than before,” Brandon adds. “I'd say we have taken on at least 25 percent more jobs, and that’s being conservative. hyperMILL has allowed us to increase our capacity and give our customers a better product faster.”

For More Information

Precision Mold and Machine Inc. / bloehr@precisionmold.com / tloehr@precisionmold.com / 586-774-2330 / precisionmold.com

Open Mind Technologies USA Inc. / alan.levine@openmind-tech.com / (339) 225-4557 / openmind-tech.com

RELATED CONTENT

-

How to Pre-Estimate Tooling Costs

The right costing software can help to improve mold quoting and production.

-

Baffle Blades in Plastic Injection Molds

Turbulent-flow plastic baffles eliminate blow-by, significantly improving cooling and cycle times.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.