Burteck Provides Total Mold Solutions, Including LSR Molds

Burteck LLC adds LSR molds to its plastic-injection moldmaking capabilities along with a new molding technology center.

Since 2015, Burteck LLC has become a total mold solutions provider by adding a variety of new capabilities. Can you review these changes and updates to your service portfolio and explain their value to your customers?

Burteck Program Manager John Eastham: The main changes and updates over the past three years are the creation and subsequent expansion of Burteck’s Molding Tech Center and its addition of LSR mold-building and testing capabilities. We also added a significant amount of new moldmaking and inspection equipment.

The Molding Tech Center opened with an Arburg 110-ton all-electric press, which covered about 80 percent of the molds that we were manufacturing. Soon after that investment, we added an Engel 340-ton, tie-barless press for testing larger, two-component molds. This installation was somewhat unique because we retrofitted a standard single-shot molding machine into a two-shot machine by adding a third-party rotary table, a second injection unit from Boy Machines and a central automation system to tie all the pieces together. This retrofit enabled us to add two-shot testing capabilities for a fraction of the cost and the lead time of a traditional two-shot machine.

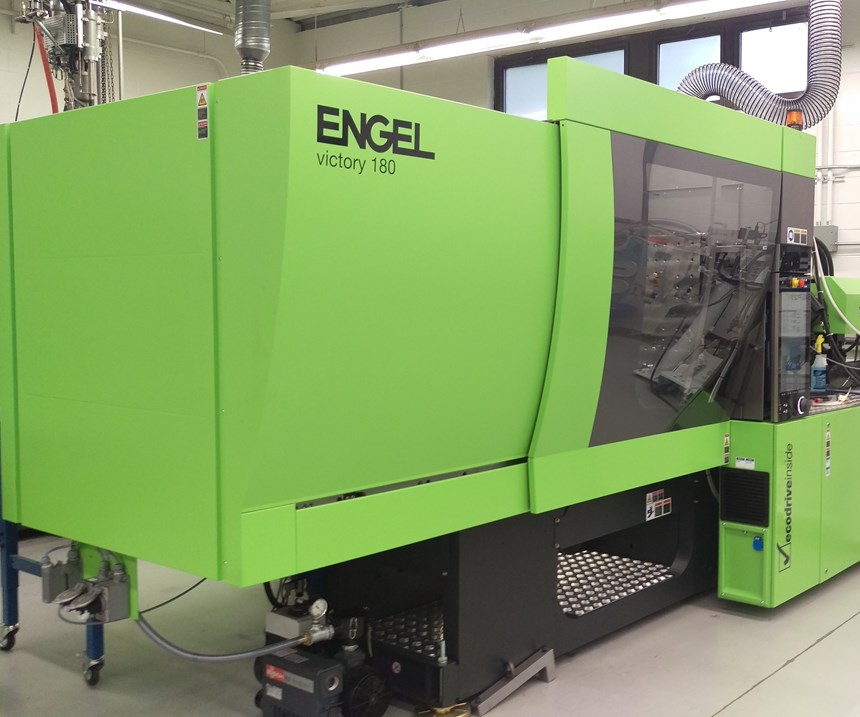

In 2017, we added an Arburg 165-ton all-electric machine. The latest addition to the shop is an Engel 180-ton, tie-barless machine configured for LSR molding, complete with a Graco LSR pump and static mixer.

On top of those four Burteck-owned machines, we dedicated space and resources for customer-owned equipment to offer turn-key solutions. We currently have three of these systems in-house. Customers who are building molds with us and who also are purchasing new equipment can drop-ship the equipment to our facility where we develop the mold, machine it and use any other auxiliary equipment in a cohesive work cell.

Lastly, we added two GF Machining Solutions wire EDM machines, two Zeiss coordinate measuring machines (CMMs), five GF Machining sinker EDM machines and a 3R Work Partner 84-station robot system to service the new EDM machines.

Explain the motivation behind these advancements.

Eastham: Burteck has always been a strong mold builder with high-quality, competitive pricing and lead times. We believed that the next step in value-add, and to separate Burteck from the competition, was to deliver a mold to our customer that is production-ready. The Molding Tech Center affords the us the ability to do functional testing, process development, qualification and pre-production runs if they are required before mold shipment. This advancement eliminates the need for our customers to allocate additional production and tooling capacity for multiple tests. Customers who purchase a molding machine or who re-task existing equipment and build a mold with us can also purchase turn-key services in the Molding Tech Center.

All of this technology and process investment has upgraded our equipment, reduced bottlenecks and established capacity for throughput gains.

All of this technology and process investment has upgraded our equipment, reduced bottlenecks and established capacity for throughput gains.

You stated that your U.S. workforce has doubled. Can you explain how and why?

Eastham: A mix of additional sales from existing customers and new customers who were interested in Burteck’s new capabilities and offerings drove that recent growth. We hired staff for the Molding Tech Center, which included two molding process technicians, a machine operator, a quality inspector and a Tech Center manager. We also hired a CMM inspector, a wire EDM technician, two additional project engineers to support tooling and turn-key programs and additional EDM technicians, CNC machinists, moldmakers and apprentices.

We work with the manufacturing programs of local vocational high schools and community colleges from which we hired four individuals. We also use industry networking, recruiters, websites like Indeed and CareerBuilder and social media platforms.

We believed that the next step in value-add was to deliver a mold to our customer that is production-ready.

Burteck is known for its plastic injection mold work, so why has it placed a recent focus on LSR molds?

Eastham: It was an easy decision. We simply believe that the demands of LSR molds align perfectly with our craftsmanship, pricing and lead times.

How did the company gain the expertise in this specialty?

Eastham: A few employees have prior experience with LSR from other companies, which gave us some initial confidence that our craftsmanship would pass the LSR “test” from a flash and functional standpoint.

We had an existing customer for which we were building thermoplastic molds, and the customer asked if we would be willing to partner three, 2-cavity LSR molds. We took this as an opportunity to jump into this process and technology. The results were highly successful. The mold functioned without any flash on the parting line, or seal offs, so we decided to add LSR tool building to our list of capabilities.

What has been the growth of the LSR-mold segment of your business so far, and where do you see it headed?

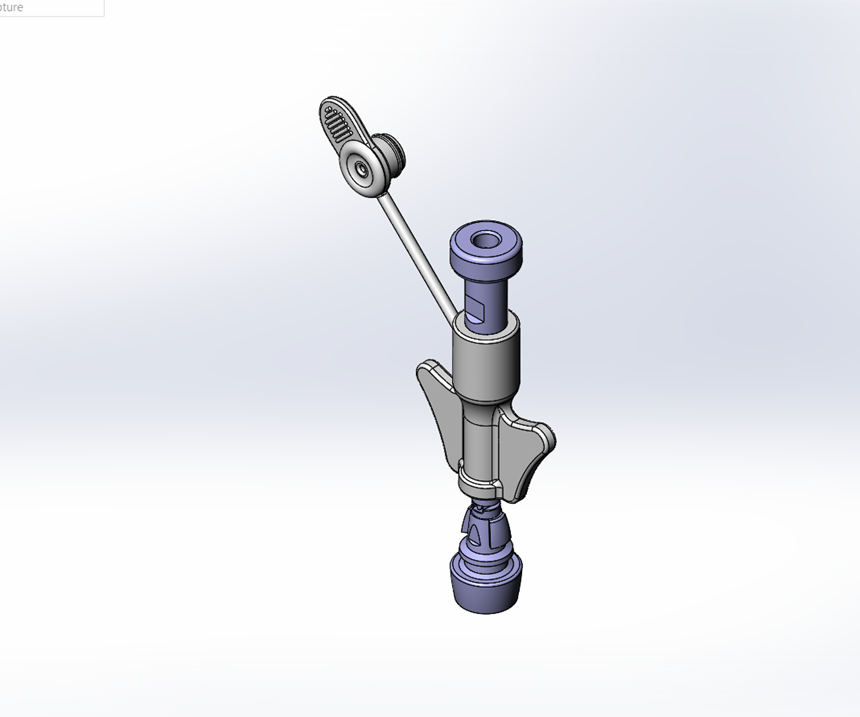

Eastham: At this point, LSR mold building is a small percentage of our business, but it is increasing. We wanted to implement our mold-testing work cell fully before releasing our LSR sales strategy. NPE2018 was the official launch of our LSR tool-building capabilities. We exhibited a two-cavity, polycarbonate and LSR two-component mold, running a medical tube port in an Engel 55-ton, tie-barless machine. The mold used a servo-driven index plate for the transfer of the first shot to the second shot and a Kipe Molds Cold Deck-MicroDeck combination for the LSR portion. The exhibit demonstrated the concept of using the first-shot thermoplastic substrate as a tooling component for the LSR overmold.

In the near future, we see great growth opportunity in LSR work. Our customers are experiencing long lead times with other LSR mold builders. In some cases, those other mold builders are even declining the work. We believe this will open up a new customer base for Burteck, first with customers requesting LSR mold builds and then with those customers contracting us for thermoplastic and two-shot applications as well.

Related Content

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreSmall, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

Read MoreMidgard Inc. Tackles Tooling Challenges and Automates Production to Keep Molds Running

This Eastern Pennsylvania molder does cavity changes daily, making its in-house toolroom critical to quickly fixing mold problems.

Read MoreNextGen Mold Technologies is Sticking to the Plan

I caught up with Dennis Goggin, president of NextGen Mold Technologies, to learn how much has changed for this startup mold builder since we last connected.

Read MoreRead Next

Small Family Mold Shop Turned Small Family Business

By aiming to improve at least one thing every day, Artisan Model Mold Owner Jonathan Stanwick turned the small family shop into a small family business.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

_970x250 4.png;maxWidth=970;quality=90)