BMW Achieves Faster Tooling/Part Inspection

Hardware-independent software for the inspection of prototypes, tooling and production samples against CAD data is being used on two Zett Mess AMPG measuring arms to inspect chassis prototypes at BMW.

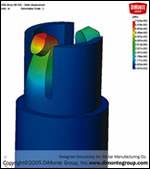

PowerINSPECT—a hardware-independent software for the inspection of prototypes, tooling and production samples against CAD data—is being used on two Zett Mess AMPG measuring arms to inspect chassis prototypes in the “Process Technology Prototype Development” of the BMW Group. The system gives faster results, and is so easy to use that it is suitable for both inspection specialists and for production experts who haven’t had training in measurement technology.

It works with a wide range of inspection devices, including static coordinate measuring machines (CMMs), and optical and laser-based systems, but is best known as the preferred software for portable inspection arms. The combination of the portability of the inspection arms and the easy-to-use software makes it practical to make many more inspections than is possible with a dedicated CMM that might be located at a considerable distance from the point of manufacture. By allowing more inspections and by giving real time results in an easy-to-understand format, PowerINSPECT allows problems to be identified earlier and corrected at lower cost.

For all types of inspection, PowerINSPECT offers two key benefits; a fast and simple, interactive method of collecting the data required and a range of levels of reporting. During the inspection, the CAD model of the part is displayed on the computer screen. All results are displayed instantly on the model so the user knows immediately that he has measured the required point. This instant feedback also allows the operator to take additional measurements in areas where the initial results indicate potential problems.

At BMW, every new chassis prototype is received by the development team as a CAD file, which is used to weld the design. Welding distortions of 3mm are the norm and have to be eliminated in a continual process of welding – inspection – correction – inspection. In the past, the inspection process for some of the parts required up to two hours; now, with PowerINSPECT, only five minutes are needed. This gives significant time savings since up to five inspection passes are required per component.

“Users are able to measure out the coordinates much faster,” said Stefan Schneider, Application Engineer, at Delcam GmbH. “Every measured point can be compared to the CAD data with PowerINSPECT. The inspection software immediately and precisely shows the deviations within the specified tolerances.”

In addition, every measurement is saved in PowerINSPECT. The software documents each modification in such a way that it becomes clear in which direction a point has to be moved in order to implement a specific change.

PowerINSPECT offers not only comprehensive functionality but also the simplest possible operation. “Many inspection programs are complicated to use,” claimed Mr. Schneider. “PowerINSPECT’s ease of use is essential for situations like that in BMW’s chassis prototype development, where both metrology specialists and production staff need to use the software.”

Easy operation and the shortest-possible learning curve allow casual users to be able to work accurately and efficiently with the measuring equipment. After only two days of training, BMW employees could use PowerINSPECT in combination with the Zett Mess arm.

Another benefit is that PowerINSPECT does not require the parts to be held in a specific fixture. Its best-fit routines mean that inspection can be undertaken in any position. In addition, the arm and software make it possible to inspect two parts simultaneously on one table. If the alignment between the two parts is known, the user can switch between the two inspection sequences.

It is also much quicker to add extra points into a measurement sequence. The additional data can be incorporated with the earlier measurements and the combined results displayed immediately, instead of having to re-measure the whole part. Similarly, it is possible to change the datum being used for the inspection and PowerINSPECT will quickly regenerate the inspection report.

Related Content

Upgrade Your Moldmaking Processes With New Innovations

Read up on new innovations, including modular sorting systems, monitoring platforms for injection molders, indexable milling cutters and more.

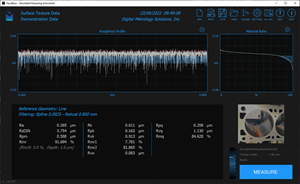

Read MoreWhat Does Surface Roughness Mean in Moldmaking?

To improve mold performance, reduce wear and produce high-quality molded parts, mold builders must understand surface texture and how to properly measure, analyze and control it.

Read MoreVIDEO: What Does Integrated Predictive Modeling Mean to Moldmaking

Although conformal cooling is not a new concept, new technologies have made it a very hot topic, including predictive engineering models and 3D printing. Learn about a new conformal cooling process and algorithm and what it reveals about hot spots and conformal cooling design.

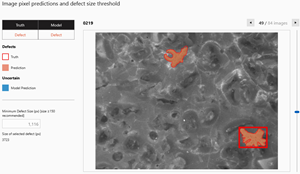

Read MoreThree Advances in Vision Measuring Technology for Moldmaking

Next-generation metrology solutions are streamlining shopfloor automation and quality control for mold builders.

Read MoreRead Next

Breaking the Mold in Mold Development

Integrated analysis capabilities streamline mold design.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_970x250 3.png;maxWidth=970;quality=90)