Automation Increases Molding Options for Zahoransky USA Customers

MMT interviews Zahoransky USA Inc. to learn more about the company’s expertise in integrating automation with the precision injection molds that it builds.

At NPE2018, Zahoransky USA Inc. exhibited and featured an array of injection moldmaking capabilities. What capabilities seemed to catch the most attention from potential customers?

Product Sales Manager, Molds, Andrew Cummings: We have many years of mold building experience and have gained a reputation for engineering molds that perform with extreme reliability. Where Zahoransky Automation and Molds (ZAM) really brings value to the table is with turnkey solutions and our ability to integrate automation in or around the injection molding process. At Zahoransky USA Inc. (Zahoranksy), we say, “from the pellet to the pallet—we can provide solutions.” For example, some of our customers have full lines that we built entirely, from the sub straight to the over-molded, inspected and packaged product. Cells like this run production 24/7 and can have as few as one operator for four machines. Another example, we run 100 percent all of the design and builds for all GUM brand interdental brushes. We impress potential customers by showing them that the right manufacturing solution for their products can be attained with only one vendor.

We impress potential customers by showing them that the right manufacturing solution for their products can be attained with only one vendor.

When did Zahoransky first introduce “in-mold” and “near-mold automation” to its moldmaking services, and how does the company determine what is required?

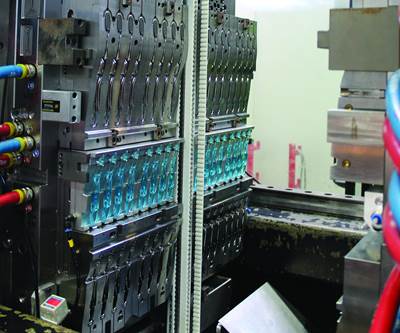

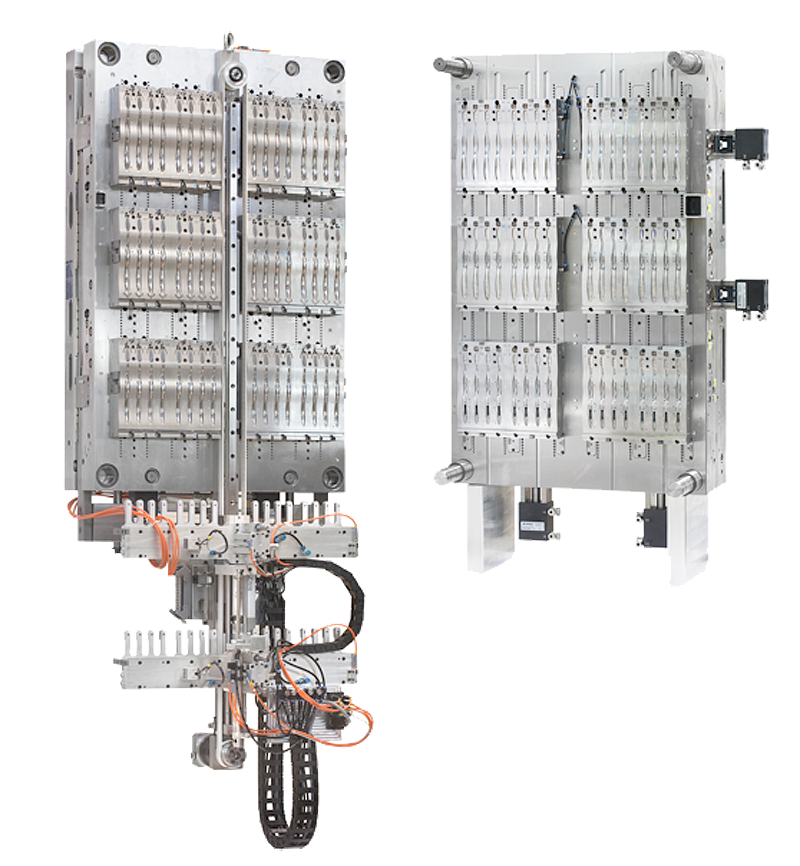

Cummings: We are implementing in-mold automation for much of our customer base. We also have superb standalone injection tools, specializing in two- and three-component applications. We are continually refining how we design the molds and automation systems, and of course this begins by being completely dependent on the molded product. Typically, we work with customers that have injection molding needs beyond just the tool. We make extremely reliable tooling, but with our expertise in integrating automation, we go far beyond that. We ask customers for more than just part specifications. We ask them what they want to do with the product after it is molded. We discuss assembly processes and packaging options. After initial discussions with the customer, we send the information to Germany where our engineers develop two to three possible solutions. Take, for example, a project for a three-piece cap and closure for e-cigarette liquid caps. The mold is a 48-cavity tool times three, or 144 cavities total. The mold produces three separate parts, each molded from different materials, and uses the end-of-arm tooling to grab the 144 parts and assemble them right outside the mold as the mold closes and begins molding another 144 parts. This is accomplished with a 500-ton Arburg machine and three injection units, each of which injects a different resin. This is a standard configuration that Arbug supplies. This cell is completed with our integration of automation using the end-of-arm tooling for assembly.

We make extremely reliable tooling, but with our expertise in integrating automation, we go far beyond that. We ask customers for more than just part specifications. We ask them what they want to do with the product after it is molded.

Depending on the parts that the customer is molding and assembling, there is flexibility in how we configure the injection units. For example, we can configure them side-by-side, piggy-backed or vertically. Regardless, the parts would still meet customer requirements. This just gives our customer the flexibility to use different injection molding machines or standard injection molding machines. The customer might be limited by space and the ceiling height, so they may want, for instance, side-by-side injection units and not vertical injection units.

Provide an example for in-mold and near-mold automation, and explain how these approaches to injection molding fundamentally are changing the way Zahoransky’s customers produce their end products.

Cummings: Honestly, we call it in-mold assembly (IMA), but typically assembly is done outside of the mold. If the assembly is done inside the mold, then it can only happen when the mold is open, which does not apply to the system I described. If assembly is done right beside the mold, the advantages are huge. For one, the customer can start to mold more parts while assembling simultaneously whereas with in-mold assembly, the customer would have to wait until the assembling is completed before the customer can shoot the next shot for molding.

Fundamentally, we are on the cutting edge of injection mold building and making this process as efficient as possible. Our expertise enables our customer to run the entire operation in-house from one manufacturing cell, often resulting in the reduction of injection-molding cycle time by having cooling towers and robots integrated right next to the mold, using any combination of our strategies to optimize the injection molding process.

Fundamentally, we are on the cutting edge of injection mold building and making this process as efficient as possible.

Often the customer can see a reduction in total product manufacturing cycle time (molding to assembly) by integrating an assembly process using end-of-arm tooling. For example, as cycle time is dependent on the size of the part that the customer is molding, we are able to take a razor body with a thick handle and reduce the cycle time by 15 seconds by using an integrated cooling tower and robot.

Innovation is a reaction to customer needs that is combined with internal engineering and testing. In every way possible, we strive to create better ways to build molds that make 100-percent good products with a fully automated process that can run day in and day out. A great example of this kind of innovation is our Z.BLIZZARD needle syringe cell. The cell uses our Z.NFS (or automated needle housing and feeding system) to automate the feeding and bending of needles before they are inserted into an injection mold and over molded. We developed it, and it is standard for molding clear plastic vials using cyclic olefin copolymer (COP) and cyclic olefin copolymers (COC). In this case, 1-ml disposable syringes were being over-molded. A cell like this will give the customer 100-percent good parts that it can mold in a clean room and fill with drugs immediately off the press. To this day, we are the only company in the world that has this technology. Zahoransky has sold several of these systems to North American customers.

Does Zahoransky have any plans to further expand its presence in the United States?

Cummings: Yes, we just moved a German technician to our mold repair facility in Atlanta, Georgia. Soon, we would like to build our own mold shop and start building molds in the United States to support our growing North American customer base.

Related Content

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreHow to Machine Micron-Level Precision Molds in One Try

On-machine measurement intelligence and modification technology helps mold builders overcome machining variables and quickly produce micron-level tolerances.

Read MoreRead Next

International Perspective: Tooling Systems Squeeze More Production out of Each Mold

Multi-component tooling systems squeeze more production out of each mold.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)