Are We Playing It Too Safe with Technology?

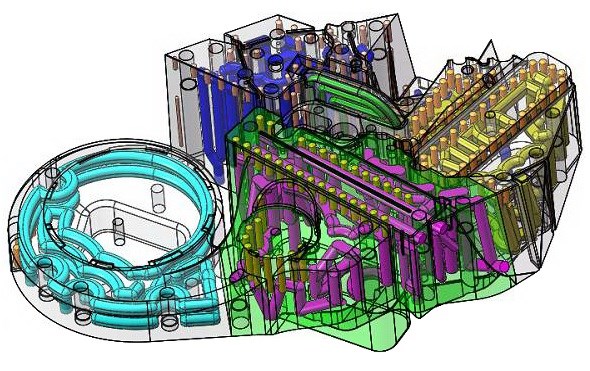

The large conformal mold shown is a highly engineered and highly complex mold that was built more than eight years ago and has molded over 1 million cycles. Are we playing it too safe and waiting for other countries to catch up before adopting this technology?

The Plastic Industry is loathe to change. When we find a technology that works, we keep it secret because it is our competitive edge. Never mind that our competitor may be half a world away. Or we wait until somebody else tries some new technology and then we wait until some key company discloses that they have tried it and it works.

This stifling of acceptance of technology is caused by a corporate environment that punishes someone who takes a technology risk that fails, costing the corporation a large amount of money, and then either demotes or fires the person who took the risk. This sends a chilling, if not disastrous, message to the people left in the corporation: Do Not Take Risks.

One of the main factors that keeps the U.S. competitive is technology. However, if we do not implement it quickly, we lose our competitive edge and other countries quickly catch up.

The large conformal mold shown is a highly engineered and highly complex mold that was built more than eight years ago and has molded over 1 million cycles. Are we playing it too safe and waiting for other countries to catch up before adopting this technology?

For more on the myths of conformal cooling, check out an upcoming new FastTrack training program on September 4th and 5th, near Toledo, OH, sponsored by Plastic Technologies, Inc. (PTI), which will feature two modules— Conformal Cooling for Injection Molding (September 4th) and Medical Plastics Design and Processing (September 5th).

Conformal Cooling Seminar Outline

1.) Understanding heat management

2.) How resin selection affects heat management.

How resins can be modified to cycle faster.

3.) Choosing the right mold metal.

4.) Understanding how Fluid Dynamics impacts Dynamic Heat Transfer.

5.) Alternative cooling technologies to be used with conformal cooling.

6.) Conforming Cooling Technologies, including a European technology

presentation not seen in North America.

7.) Examples why Moldflow and Computational Fluid Dynamics (CFD) are important,

if not necessary, tools for designing conformal cooling channels

Robert Beard, P.E. President, Robert A. Beard & Associates Inc.

rabeard@Plastic-Solvers.com / www.plastic-solvers.com/