Are Copper Beryllium Molds Safe?

One study indicates that there is little risk of transfer of beryllium to the finished molded-plastic product.

Copper beryllium alloys are heavily used worldwide in the plastic industry in the manufacture of injection mold components that are then used to make containers from different types of plastic resins. It is estimated that 50 percent of the U.S. plastic injection industry uses this material for this purpose.

And it is easy to see why moldmakers choose this material.

The superior thermal properties of copper beryllium alloys help rapidly remove heat from plastic parts manufactured by the molds, potentially reducing cycle times by 15 to 50 percent while also maintaining good hardness and limiting the need for repair and refurbishment of the molds.

When those plastic parts are containers used for food storage, however, it raises concerns about any transfer of copper beryllium from the mold to the containers to the food and, ultimately, to the consumer of that food.

Beryllium is an element that shows up naturally in soil, air, water and unprocessed foods. Research arrives at varying conclusions as to what normal daily beryllium intake is from food and water, but the average human consumes an estimated 35 mg of beryllium, according to science writer John Emsley’s 2011 “Nature’s Building Blocks: An A-Z Guide to the Elements.” Studies, including a 2010 experiment from the Annals of Occupational Hygiene, have concluded that ingestion of beryllium poses no health risks, but there are also discrepancies in what research has concluded is a safe and recommended intake level for humans. Government agencies responsible for food safety remain concerned about the potential unidentified toxicological effects of oral consumption of beryllium. For example, the U.S. Food and Drug Administration (FDA) regulations (Chapter 4-102.11 and Chapter 4-201.11. FDA code 2013) require that “Materials that are used in the construction of utensils and food-contact surfaces of equipment may not allow the migration of deleterious (harmful) substances or impart colors, odors, or tastes to food.”

A 2001 Concise International Chemical Assessment Document (CICAD) from the World Health Organization determined that a tolerable amount for a human to ingest is 0.002 mg per kilogram of body weight per day. For a 60-kg (132-pound) person, this amounts to 0.12 mg of beryllium per day. Using this estimate, the Council of Europe in 2013 set a “specific release limit” (SRL) of 0.01 mg/kg per day, meaning that a reasonably safe oral intake level of beryllium is 10 percent of the CICAD’s toxicological limit of 0.002 mg per kilogram of body weight per day, assuming a 60-kg person consuming 1 kg of food.

For manufacturers that use copper beryllium to make molds, the SRL serves as a guide as to how much beryllium can be released from plastic food-storage containers made from such molds into food without endangering the health of consumers. The specific release (SR) is measured as the difference between the concentration of the element in the food before and after contact with

the metal or alloy, so the naturally occurring quantities of the element are also taken into account. If the SR is below the SRL, the mold manufacturers are in compliance with safety guidelines recommended by the European council.

A 1990 study from Foley Occupational Health Consulting concluded that beryllium levels in finished plastic items produced in molds containing copper beryllium alloys were below a detectable limit of 100 parts per billion (ppb). Late last year, Materion Performance Alloys conducted its own study to further prove that the use of copper beryllium as a tooling material does not risk the transfer of beryllium to the finished molded-plastic product.

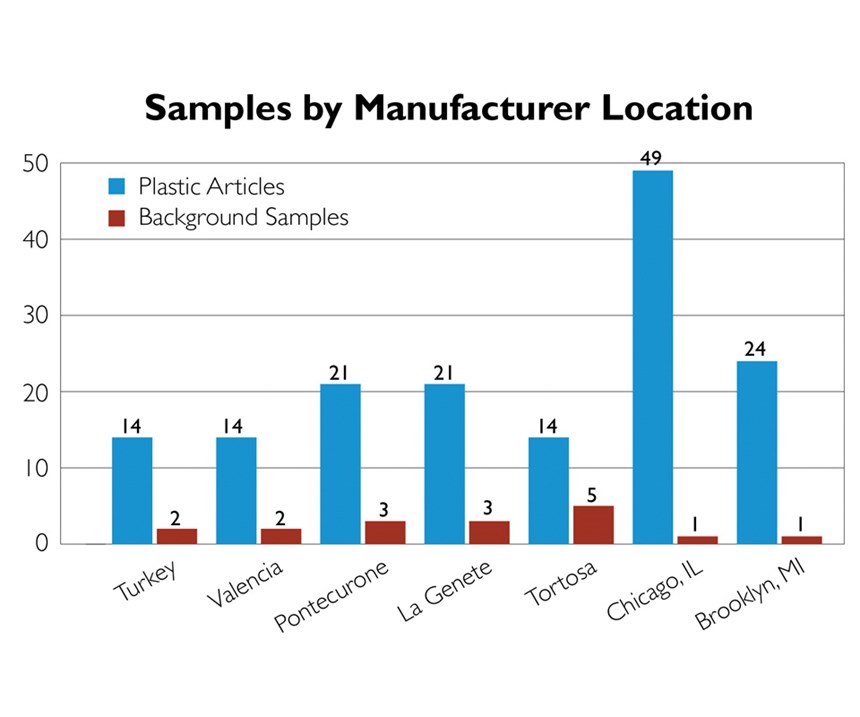

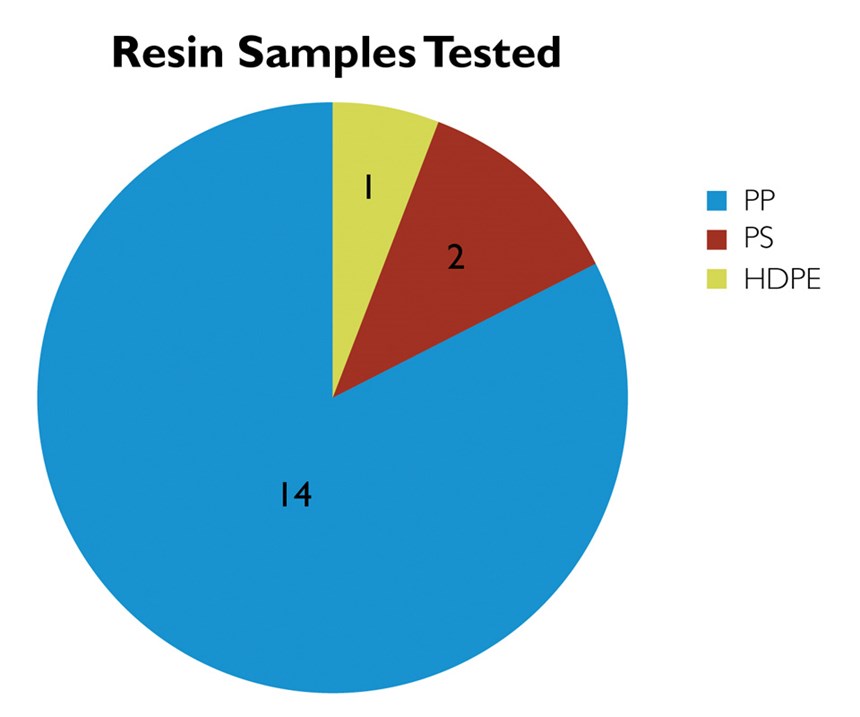

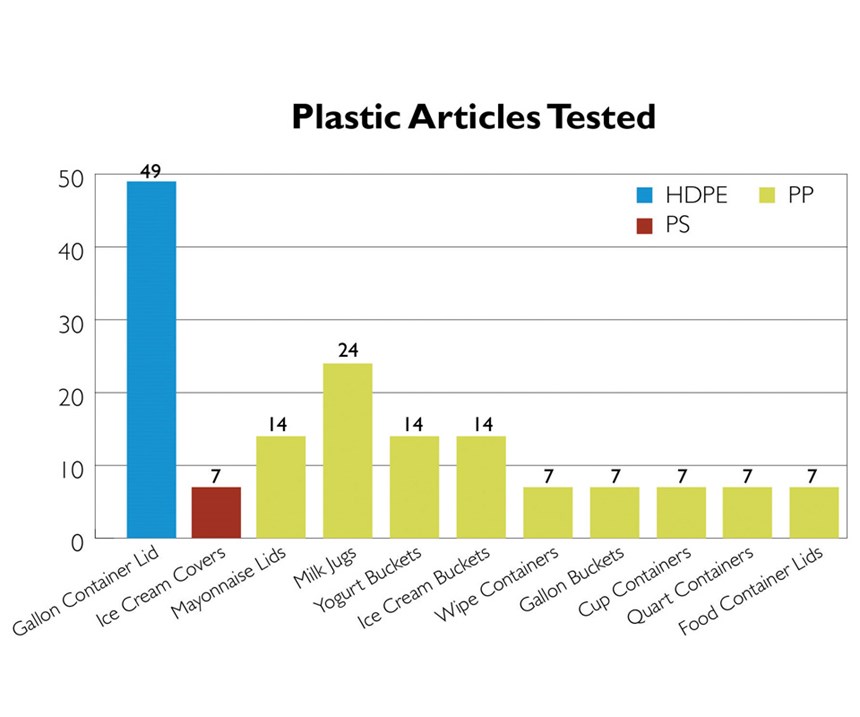

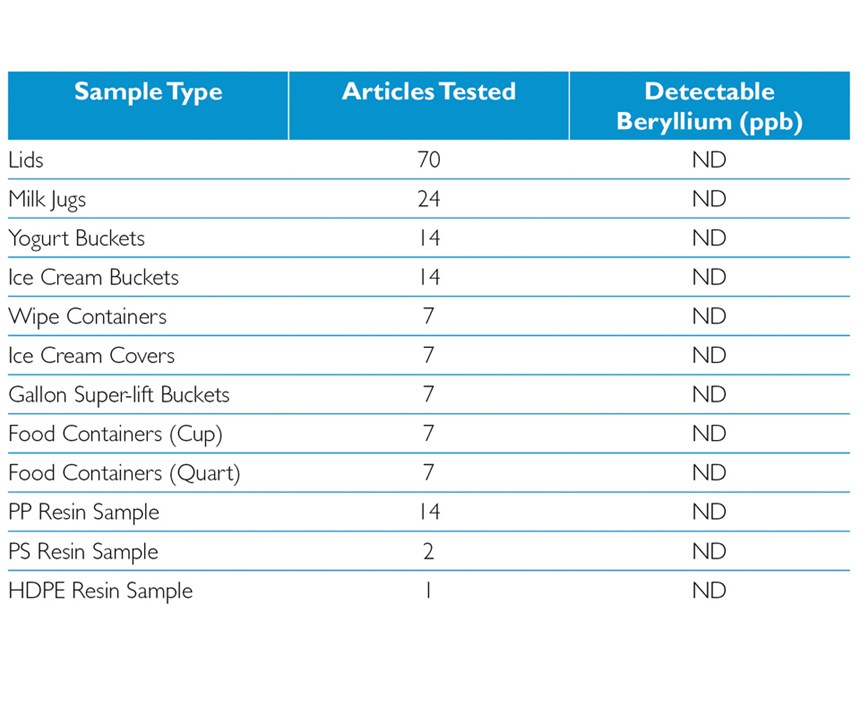

For this study, a total of 157 various plastic food packaging containers were collected from manufacturers that use copper beryllium alloys in their plastic injection and blow mold tooling. Samples of the raw materials that comprised the finished products were also obtained. The molded plastic specimens and resin samples were then analyzed for the presence of beryllium (see charts).

After sampling, a laboratory accredited by the American Association of Laboratory Accreditation tested the plastic containers for residual beryllium according to the EPA6010C method used to determine trace elements: inductively coupled plasma atomic emission spectrometry (ICP-AES). (This method is recommended by the European council as an appropriate analytical technique for release testing of materials made from metals and alloys that will make contact with food.) For this particular analysis, the samples were boiled in a nitric acid solution for 20 minutes, dissolved in a nitric acid solution for 12 hours and subsequently analyzed by ICP-AES.

Of the 63 laboratory tests run on the samples, all were negative for detectable beryllium. The elemental chemical analyses performed verified that the beryllium levels were not above 10 ppb in any of the plastic items or resins taken from the injection molders, thereby complying with the FDA regulations on harmful substances. The overall conclusion of this study was that beryllium was not transferred in measurable amounts from the molds to any of the specimens.

These findings suggest that the transfer of beryllium to plastic food containers does not occur and serves as relevant data to show that copper beryllium alloys can be safely used in molds that produce plastic containers expected to come in contact with food.

Read Next

A New Beryllium Standard

A proposal to set a lower exposure standard for beryllium and beryllium-containing materials will affect how the plastics industry handles and processes these materials.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)