amerimold 2011 Show Review

Experience the people, the products and the processes that made amerimold 2011 a success!

The amerimold exhibit hall included more than 100 exhibitors displaying technologies ranging from 5-axis machining centers to 3D printers; simulation software to cutting tools; mold components to materials. The show enjoyed increased exhibit hall attendance in 2011. The average amerimold exhibitor collected more than 55 well-qualified leads and there were multiple reports of show floor equipment sales.

| View Images from amerimold 2011 | ||

|

|

|

Related Content

Expansion of Online Moldmaking Catalog Streamlines Mold Component Search and Sourcing

DMS Components has launched a new part number lookup feature and 3D PDF facesheets to improve the online experience for design engineers and purchasing departments when searching for mold components.

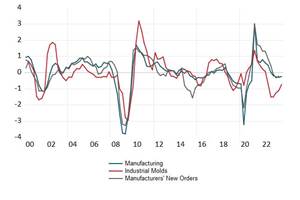

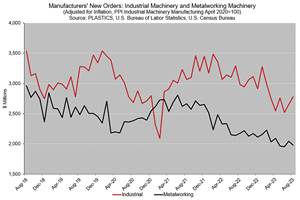

Read MoreNavigating Economic Resilience and Consumer Trends

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreResilience and Reflections: Moldmaking in the Evolving Economic Landscape

As moldmakers navigate this complex year marked by fluctuating business activities, and approach the upcoming year with cautious optimism, three key considerations should guide their decisions.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 1.png;maxWidth=300;quality=90)