Moldmakers want better cutting-tool performance. MoldMaking Technology reached out to cutting-tool suppliers to gather intelligence about the current trends and challenges that they are seeing and what strategies are in place to respond to customers’ needs.

The Need for Higher Feeds and Speeds

Ultimately, moldmakers strive for faster metal-removal rates to be competitive and profitable, and cutting-tool suppliers are hearing it loud and clear. Jay Ball, product manager for Solid Carbide Endmills North America at Seco Tools LLC (Troy, Michigan), says, “Customers are starting to adapt more complex machining strategies like ‘optimized roughing’ and complex five-axis machining using barrel-style cutting tools into their daily manufacturing processes.” He says that optimized roughing is attained by using well-defined tool paths with a constant arc of contact, taking large depths of cut (DOC) and small radial stepovers combined with high feed rates. Using barrel-style tools enables larger DOC compared to standard ball-nose geometry when finishing complex 3D surfaces. “Moldmakers are starting to use these tools to help reduce finishing cycle times to increase throughput,” he says.

Customers are starting to adapt more complex machining strategies like optimized roughing and complex five-axis machining using barrel-style cutting tools into their daily manufacturing processes.

William Fiorenza, product manager for Die and Mold at Ingersoll Cutting Tools (Rockford, Illinois), says that economy in finish milling is every bit as important as optimizing roughing. “Finish milling consumes a considerable amount of time. Most 3D contour finishing is performed with a solid-carbide, ball-nose end mill or a ball insert with an indexable carbide blade. Finishing times tend to be long with the programmed stepovers and stepdowns being tied to a desired surface finish,” he says. “While CAM companies offer some very powerful programming algorithms to help reduce the time in the cut for ball-nose-type finishing, there are part features that can benefit from other types of geometries. We are starting to see the development of indexable tooling that incorporates larger radii. When this is designed into indexable, precision tooling, it allows for shorter cycle times because one can take greater stepdowns and still maintain a good finish. Die and mold builders will undoubtedly find a home for this type of tooling.”

Ed Francis, vice president of Imagineering at Crystallume (Santa Clara, California), says that many mold shops have started to hard mill as much as possible to cut down or eliminate the machining of graphite electrodes for EDM. “This eliminates multiple instances of fixturing the mold as various operations are performed on it,” he says. “However, it is still a challenge for very fine detail since the small diameter tools with the reach required may deflect too much. The tolerances on the molds and parts that moldmakers produce have also become tighter—a couple of microns in some cases—necessitating that the tolerance of the cutting tools also becomes tighter. Customers sometimes ask me what kind of exotic molds require these new, tight tolerances, and I tell them to think of a multi-blade razor where one blade is a few tenths taller and peels off a layer of your skin. Even a commodity item like a razor needs these types of tolerances.”

Bill Pulvermacher, director of Product Marketing for YG-1 Tool Co. (Vernon Hills, Illinois), says, “The challenges are always about the time, the repeatability of the processes and the surface quality to reduce or, even better, avoid hand polishing.” He says that customers also are requesting carbide-grade indexable inserts to machine the finish. Kedar Bhagath, chief technical officer at Tungaloy America Inc. (Arlington Heights, Illinois) says, “Inserted-type cutters are desired for cost savings and to avoid regrinding, while head-exchangeable types also help to avoid having to regrind edges.”

Steve McBride, manager of the High Tech Group for OSG USA (Glendale Heights, Illinois), says that typically, in deep hole drilling of over three times the tool diameter, it is

acceptable to do multiple pecking. This means that the machinist drills three times the diameter in one peck and then begins pecking or drilling in smaller depths until the required depth is reached. “These multiple pecks cost a lot of cycle time. A machinist may have a drill that will drill up to 30 times the diameter in one continuous peck and at faster feed rates. The reduction in cycle times is mind boggling for anyone who has not used one,” he says.

Smoothing the Roughing Process

Drew Strauchen, vice president of Marketing and Business Development at Haimer USA (Villa Park, Illinois), says, “We are seeing more customers using anti-pullout shanks in conjunction with high-helix end mills for roughing, in which the helix is greater than 30 degrees.” He explains that I-machining (also called full-radial engagement trochoidal milling) has become a popular machining method for roughing, but because of higher degrees of engagement between the high-helix end mill and the workpiece, the process often generates greater pullout forces for end mills with diameters larger than 0.375 inch. Forces that can cause the end mill to twist and pull out like a corkscrew opening a bottle of wine. “Using an anti-pullout shank prevents the cutting tool from pulling out of the tool holder because special drive keys match the spiral-shaped grooves on the cutting-tool shank, creating frictional clamping forces and a positive locking form-fit,” he says. “This also helps increase productivity because it enables faster permissible speeds and increased tool life.”

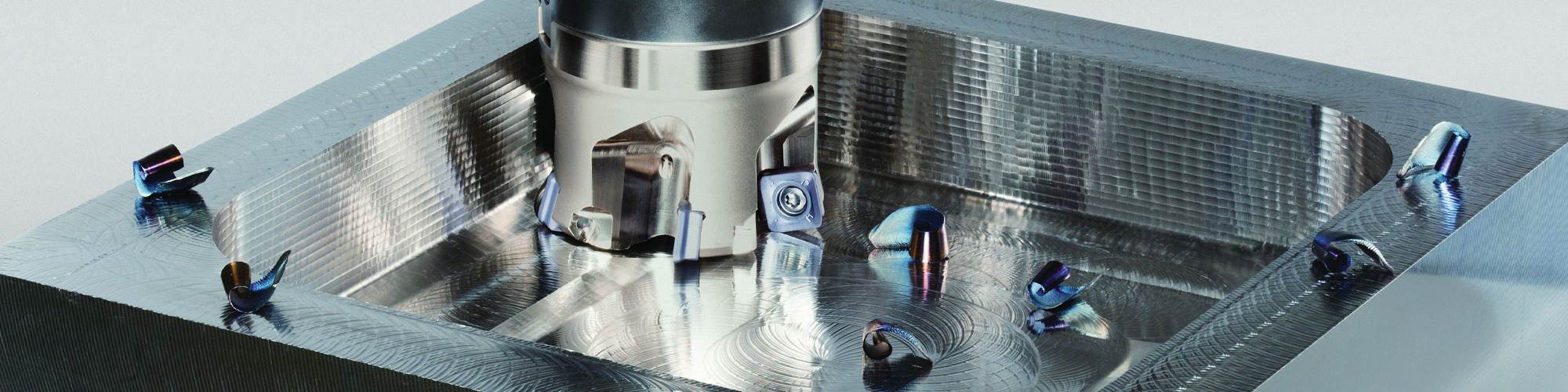

Ingersoll Cutting Tools’s William Fiorenza notes that many cutting-tool companies continue to refine indexable insert designs to maximize the number of cutting edges per insert. “This provides for maximum economy when roughing,” he says. “Additionally, insert rake-face geometries and edge preparations continue to be optimized for specific material types and cutting conditions.” He explains that rake-face geometries and edge preparations serve to reduce cutting forces through insert design features that create freer cutting and sheering action while still maintaining strength. They also help reduce cutting forces in short and long tool-reach milling applications, reduce the amount of heat that goes into the workpiece and do a good job of carrying away the heat produced during the cutting action via well-formed chips that absorb that heat. “The die and mold industry often contends with extended reach applications that require long length-to-diameter ratios,” he says. “Well-designed insert geometries, cutting-edge preparations and coatings help them deal with these challenging applications as well as others, including interrupted cuts, re-cutting of chips, full-channel cutting or large radial engagements and milling specialty mold and die steels, soft non-ferrous materials and some high-temperature

stainless steels.”

“Roughing with high speeds have become a reliable practice with customers,” Kedar Bhagath of Tungaloy America Inc. says. “Customers are moving away from traditional button-insert cutters and adopting high-feed milling solutions that provide a constant approach angle of 10 to 17 degrees versus using a round insert where the approach changes for each DOC. Tooling materials are getting harder than the traditional P20 or H13, with anything over 36 HRC increasing the possibility of insert chipping and subsequent damage to the body of the tool if the cutting parameters are not optimum. Generally, machining of hard mold bases usually requires that the DOC and cutting speeds be lowered to achieve consistent tool wear. Yet, depending on the machines in question, larger DOC capabilities in high-feed machining are in demand, driving tool makers to develop better geometries and insert grades to higher reliability and consistency.”

OSG USA’s Steve McBride says that OSG USA offers exchangeable head and solid-carbide end mills with three to six flutes that are specifically designed for machining very deep applications in the range of six to 20 times the tool diameter. “This depth range is very difficult to machine using typical end mills because of extreme tool push off,” he says. “Most

customers decide to use EDM on these deep applications, resulting in much longer cycle times and an overall higher cost. The bottom line here is that machining cycle times can be greatly reduced by using solid-carbide tools to eliminate EDM processes wherever possible.”

Jay Ball of Seco Tools says that many cutting-tool companies have invested heavily in advanced multi-flute geometries (with five, six, seven and nine being the most common) because more flutes enable faster feed rates which in-turn reduce cycle times. “By adding variable geometry to help break up chatter and harmonics, incorporating unique chip splitters to aid in chip evacuation in deep-pocketing applications and incorporating the latest in carbide substrates and coatings, multi-flute tools are leading the way in process optimization.” However, with so many new strategies and cutting tools flooding the market, it can be hard to determine which advanced strategy is best for the customer’s application, according to Ball. “Each strategy has its benefits, but there are also certain criteria that must be taken into consideration to make these strategies effective, like machine limitations (lack of rpm, horsepower, feed-rate capabilities and so on), not having the right programming software to take advantage of new strategies or simply that the specific component that the customer is trying to machine does not contain adequate features.” For example, he says that optimized roughing is better-suited for straight-walled parts and is not always the best solution for complex 3D surfaces. “High-feed roughing would be a better option in this situation.”

Getting More Value Out of Every Cut

Every machinist worth his or her salt knows how important it is to keep cutting tools in good, working condition by monitoring them and setting them up properly for each job. But, there is so much more to consider when looking to prolong a cutting tool’s utility before having to spend money to replace it.

Haimer USA’s Drew Strauchen says that moldmakers can benefit by using fine-balanced cutting-tool assemblies that are physically inspected and modified as needed to provide perfect balance characteristics, which in turn have a positive impact on tool life and part finishes. “Unbalance creates centrifugal forces during spindle rotation that creates vibration, which translates to less tool life, poorer finishes, increased spindle wear, more runout and ultimately leads to a reduction in cutting speeds (or metal-removal rates). The faster they go, the more obvious the unbalance problems become,” he says.

Crystallume’s Ed Francis says that moldmakers want longer-lasting and tighter-tolerance cutting tools. “Coatings have advanced with the latest AlTiN coatings for hard milling with the addition of small elements (at less than 1 percent) that promote hardness at high temperatures, like carbon, silicon, boron, oxygen or yttrium,” he says, adding that another trend in both PVD and diamond coatings is a move toward a nanocrystalline coating structure to ensure good uniformity and to maintain tight tolerances when using carbide cutting tools. He says that the measurement of cutting tools to microns also is quite difficult for most shops, so they need to rely on information that the manufacturer supplies. Measuring the diameter and the end radius of an end mill within a micron is a very difficult task, even for the manufacturer. “Currently, most programs would need to be reprocessed if the tool changes diameter from what was programmed. Crystallume is responding by tightening the tolerance of the cutting tools it sells, adding advanced coatings and supplying individual tools that are accurately measured. Also, some of the new five-axis machines can compensate for tool diameter and radius, making it easier for moldmakers to correct any variations that may occur,” he says.

National Product Manager-Milling at Iscar (Arlington, Texas), Thomas Raun, says that the introduction of new coatings that are harder and more wear-resistant has resulted in moldmakers gaining up to 50-percent greater tool life, especially in hard-milling applications that generate higher temperatures in the cutting zone. Product offerings for indexable-type cutting tools also continue to advance, he says. “To press an insert with basic geometry is simple. To press an insert with aggressive geometries, which results in more effective shearing of material (especially difficult-to-machine materials), is one of the aspects that separates the best cutting-tool manufacturers from the average.”

Still, Raun believes that moldmakers are not making the most out of their cutting-tool investments, and this plays into the overall theme of low productivity. “Moldmaking is inherently a ‘one-off’ environment, so there is usually a lot of programming and set-up time. There can be pressure to get machine tools up and running and not a lot of time to think about how the cutting tools are being applied. Better that the boss walks by a machine that is up and running, even if it is not operating effectively in terms of how the cutting tool is functioning,” he says. “I witness a lot of ‘waste’ in terms of carbide utilization. Simply put, most people are not using what they are paying for.” To help remedy that situation, Raun says that Iscar has created many apps and software packages, including the Iscar Tool Advisor, which users can leverage to gain quick access to cutting-tool recommendations and cutting parameters. Users can input application requirements, and the software selects the best available solutions. Examples include cutting-tool recommendations, cutting data, power requirements and productivity outcomes for each suggested result.

I witness a lot of ‘waste’ in terms of carbide utilization. Simply put, most people

are not using what they are paying for.

Solutions in Education and Collaboration

The die and mold industry faces some of the same challenges as every other industry, in terms of its people, systems, machines, tooling, software and hardware, according to YG-1 Tool’s Bill Pulvermacher. But, the die and mold industry also faces some unique challenges with difficult, long and complex roughing cycles and very long and sometimes very complex finishing cycles that require hand finishing and other laborious tasks. “This is where YG-1 Tool, in partnership with machine tool builders, CAM software developers and some forward-thinking end-users works to design and develop effective cutting-tool solutions,” he says. “For example, YG-1 Tool has developed roughing end mills with chip splitters that allow the tools to take much longer length of cut, stay in the cut longer and remove more material in less time through trochoidal and high-speed milling. The chip splitters make smaller chips that are easier to clear, and balanced cutting forces (which help attain longer lengths of cut) enable the end-users to get the most out of their CAM software and the speed of the machine tool.” Additionally, newly developed barrel cutters help to finish workpieces much more productively, Pulvermacher says. “This finishing technique, utilizing the five-axis machine tool and innovative CAM software, promotes notably longer tool life, produces better finishes and a much quicker cycle time on what is normally a long and tedious cycle.”

Similarly, Iscar’s Thomas Raun says that collaboration with CAM companies has resulted in built-in strategies that optimize cutting-tool use in terms of tool path and the cutting parameters that are being applied. “In the future, Iscar will continue its efforts to work with CAM companies to make the programming of cutting tools quicker and more productive. This will have a positive impact on the challenges of poor cutting-tool utilization and of effectively keeping the machines up and running,” he says.

Jay Ball of Seco Tools says that education is a key element in driving customers to the best cutting-tool solutions. “To help customers adopt new, advanced cutting-tool strategies, Seco Tools is taking a new approach with its literature and training materials and is incorporating more technical cutting data, ‘tips and tricks’ and advanced machining calculations,” he says. “On the digital side, Seco Tools has invested in a cutting-data or cutting-tooling solution on its website called ‘Suggest,’ which is an advanced, online product-selection tool that will guide users to the right metal-cutting solutions that are perfectly matched to unique application requirements.” He says that some of these solutions may include the recently launched range of hard-milling end mills with optimized cutting geometry for machining tool steel from 48 to 65 HRC.

Ingersoll Cutting Tools provides annual, live seminars to help die and mold manufacturers properly apply the right cutting-tool technology on a project. The company uses a combination of classroom discussions, multimedia presentations and live cutting demonstrations to introduce a wide variety of products and solutions to fit various machining needs. While most of these seminars are held at Ingersoll Cutting Tools’s headquarters in Rockford, Illinois, the company also has mobile seminars to bring solutions to customers across North America.

Related Content

ICYMI: MMT Chats: True Leadership Leads to Mentoring, Part 1

This trio from TK Mold and Engineering in Romeo, Michigan, joins me to discuss the role of leadership and culture in mentorship. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)