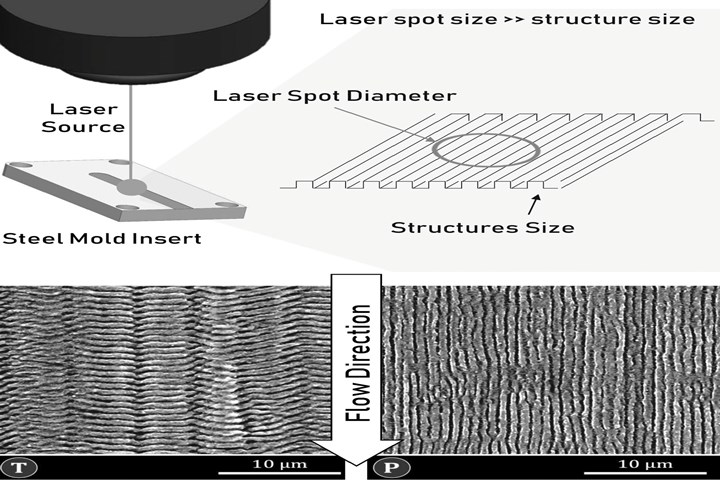

SEM micrograph of LIPSS aligned in two different directions. Photo Credit: The Department of Plastics Engineering at the University of Massachusetts Lowell and the Department of Industrial Engineering at the University of Padova.

The Mold Technologies Division (MTD) of the Society of Plastics Engineers (SPE) has been organizing technical talks at the ANTEC conference for many years. At the beginning of this year, the MTD board was excited to travel to San Antonio, host a session and engage mold technology discussions with industrial and academic participants. However, the COVID-19 pandemic forced SPE to revisit the plan and transform the event into a virtual conference.

The SPE's ANTEC 2020: The Virtual Edition occurred for six weeks between March and May. The MTD hosted technical talks online through Zoom meetings, allowing more time for Q&A sessions and virtual interactions. The MTD board reported great satisfaction in the increased number of participants listening to the presentation and for the efficacy of the follow-up Q&A and discussions. At the same time, attendees indicated the importance of in-person interactions, indicating the higher efficacy of a face-to-face conversation.

Conversations focused on different functionalization technologies, including ultrafast laser texturing, surface modification with coatings and surface activation using plasma.

Different teams presented their research projects carried out at different universities across various countries, including the U.S., Italy and Germany. The high-quality presentations were delivered by young graduate students, who all exhibited great enthusiasm for mold technologies innovations and moldmaking. Further, the technical content of the talks highlighted an exciting focus on mold surface properties and functionalization.

Although each project was unique, a theme emerged—collectively, they focused on identifying and testing innovative properties of injection mold surfaces. Conversations focused on different functionalization technologies, including ultrafast laser texturing, surface modification with coatings and surface activation using plasma. The promising benefits introduced by their advanced technologies could open up exciting opportunities for the moldmaking industry.

Surface properties of plastic products have been successfully functionalized by injection molding for several applications and market segments. Texturing enables the creation of a wide range of surface features on multiple scales, from the millimeter range down to the nanometer range. In general, the mold surface is textured to replicate a specific surface functionality on an injection molded product. Different functionalities have been achieved, such as antimicrobial, optical, aesthetical, friction and more.

When considering mold surface functionalization, limited information is available. In general, there are two main approaches for mold functionalization: surface generation or texturing and surface modification. Textures on mold surfaces can be realized with etching, micromachining, lithography, laser ablation and more. Most technologies require dedicated equipment and skilled technical personnel to guarantee accuracy and precision at the micrometer or sub-micrometer scale. Moldmakers usually source these resources from specialized partners, which only focus on surface texture design and manufacturing.

On the other hand, coatings can modify the mechanical and chemical surface properties by deposition of a thin layer of ceramic materials. This approach helps to increase tool life by resolving wear issues, which could be accentuated when using high-viscosity or filled resins. However, the polymer/coating interfacial interactions are not straightforward, as interfacial chemistry and processing thermodynamics play a significant role.

Although each project was unique, they all focused on identifying and testing innovative properties of injection mold surfaces, sparking discussions about new opportunities for the moldmaking industry.

Mold Surface Treatment Findings

Understanding the effect of a specific mold surface treatment on the injection molding process requires the study of interfacial phenomena that are not easily monitored. These researchers used sensors, machine wiring, and data analysis to evaluate the effect of mold surfaces on the injection molding process. Three main findings were presented: (1) the effects of surface properties on polymer filling, (2) ejection and (3) activation for multi-material injection molding.

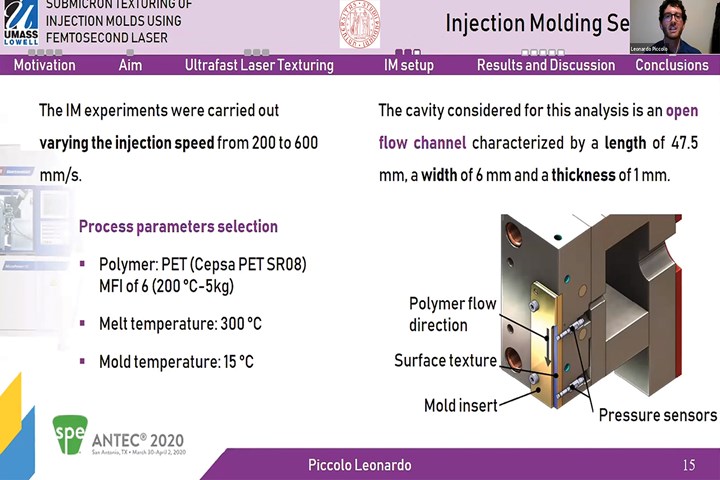

1. Effect on Filling: Submicron Texturing of Injection Molds Using Femtosecond Lasers

Researchers from the Department of Plastics Engineering at the University of Massachusetts Lowell presented the results of a collaboration with the Department of Industrial Engineering at the University of Padova (Italy). The team analyzed the effect of surface textures on the polymer filling flow, reporting the beneficial reduction of the injection pressure. The femtosecond laser was used to generate ripples with dimensions smaller than one micrometer (or 0.04 thousandths of an inch). The texturing process exploits the high energy per unit of area (accumulated fluence) delivered to the mold surface, which controls the micro- and nano-structures’ dimensions and regularity.

It is crucial to notice that the laser does not directly ablate the steel; however, it leaves its ‘fingerprint’ on it while scanning. The generated submicron structures are laser-induced periodic surface structures (LIPSS), and their application in plastic injection molding is growing.

The texture was aligned in different directions to the polymer flow by controlling the polarization direction of the laser beam. They inspected the quality of the texture using advanced metrological equipment, such as scanning electron microscopy and atomic force microscopy. Then, their effect on the injection pressure was measured using an experimental injection molding setup in which different mold inserts were changed in a mold base.

The effect of the structures, when aligned to the polymer flow, was a 7% reduction in injection pressure. In the presentation, researchers explained this effect, considering the rheological behavior of the polymer melt in the cavity. The submicron texture favored the slipping of the polymer melt at the interface with the mold surface. The results could help to design thinner plastic, creating opportunities for the reduction of plastic consumption. Also, the texture could be used to improve the processing of high-viscosity resins, such an engineering or post-consumer grades.

Injection mold setup used to study the effect of texturing during the filling phase. Photo Credit: The Department of Plastics Engineering at the University of Massachusetts Lowell and the Department of Industrial Engineering at the University of Padova.

The team of researchers has recently patented the technology (Italian Patent N. 102018000001348, International PCT/EP2019/050818) and will continue to study the fundamental aspects of the polymer/mold interface interactions.

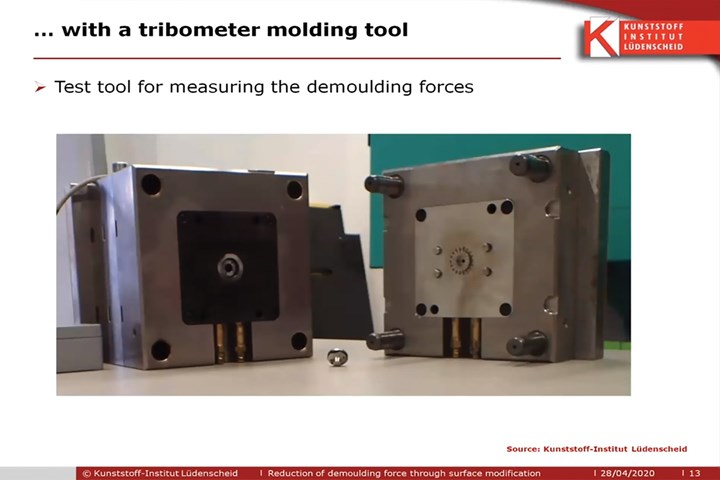

2. Effect on Ejection: Reducing Demoulding Force with Surface Modification

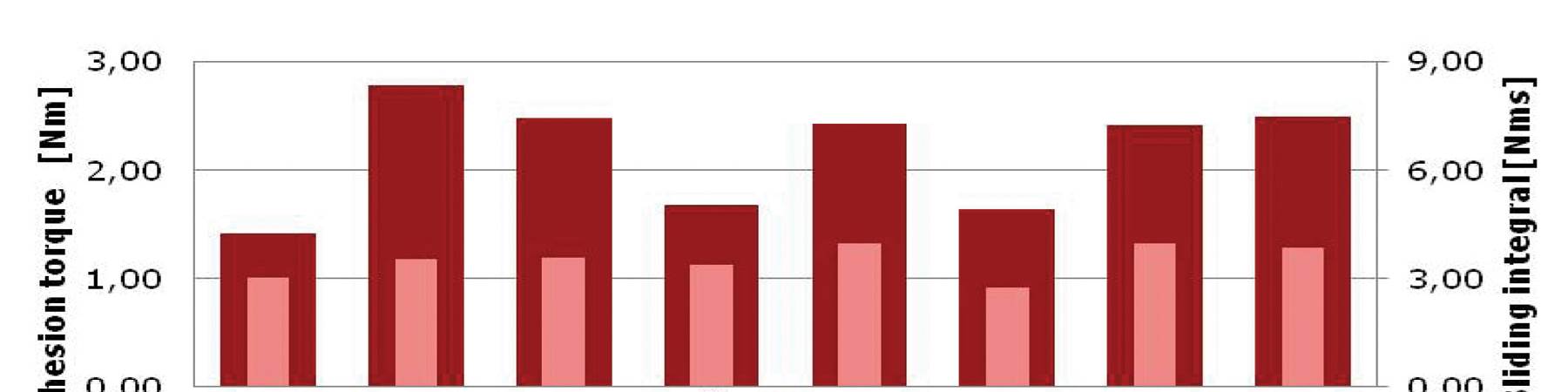

This study by researchers from the Gemeinnützige KIMW-Forschungs-GmbH (Luedenscheid, Germany) and the Kunststoff-Institut für die mittelständische Wirtschaft NRW GmbH (Luedenscheid, Germany) both focuses on the effects of mold surface coatings on the ejection force. The evaluated ejection force on an instrumented mold looks at friction torque between molded plastic and a coated mold insert.

Using the experimental set-up, they studied the influence of mold surface properties concerning injection molding parameters and resin properties. They modified the cavity surface using TiN, CrN, and chemical Ni+BN coatings. They also considered different mold textures, such as sandblasting, mirror finish, EDM, chemically etched and other differently polished surfaces.

Injection mold used to characterize the effect of coatings on the ejection force. Photo Credit: The Gemeinnützige KIMW-Forschungs-GmbH and the Kunststoff-Institut für die mittelständische Wirtschaft NRW GmbH.

The results indicate that different resins lead to very different static and dynamic friction behavior upon ejection, and that some polymers (e.g., POM) exhibit very stable behavior, while with others (e.g., PC/ABS), the standard deviation between repeated ejection force measurements is much higher.

The coatings were effective in reducing the static and dynamic friction when compared to the uncoated insert. However, it is worth noticing the various effects that the treatments have with different resins, suggesting the need to study the polymer/mold interactions during ejection. The effect of higher surface roughness is an increase in ejection force due to higher adherence.

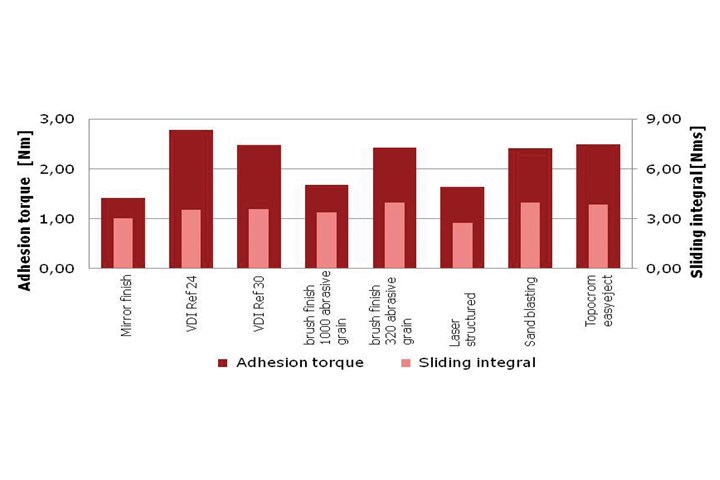

Ejection parameters measured for different mold surfaces using the instrumented mold. Photo Credit: The Gemeinnützige KIMW-Forschungs-GmbH and the Kunststoff-Institut für die mittelständische Wirtschaft NRW GmbH.

3. Effect on Bonding: Inline Surface Activation in Multi-Injection Molding

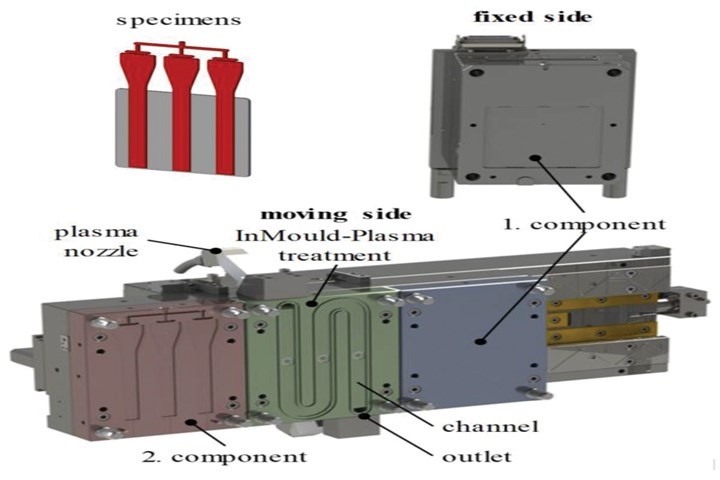

The researchers from the Kunststofftechnik Paderborn at the University of Padeborn (Germany) presented a study in which they used plasma activation to bond the surface of two polymers inside an injection mold. The use of InMould-Plasma technology allows the bonding of incompatible resins in a multi-material injection molding process.

Surface activation with plasma (a partially or entirely ionized gas) is a widely used bonding technology; however, it is usually adopted outside of the mold as a post-processing operation. In their work, the researchers studied the integration of the technology inside the mold, eliminating the need for an additional process step.

Injection mold equipped with the InMould-Plasma surface activation and bonding system. Photo Credit: The Kunststofftechnik Paderborn at the University of Padeborn.

The experiments were carried out using the InMould-Plasma technology integrated into a modular, three-station, two-component overmolding tool. The mold produces peel test specimens using a soft and a hard polymer. In the first injection molding station (blue mold plate), a square plate is molded in the fixed mold side. The second station (green mold plate) is the plasma station, which slides in front of the previously injected plate. The surface activation follows the pattern of the curved channel in which the plasma is flowing. Finally, the second polymer is injected over the functionalized surface in the third station (brown-red mold plate).

Measuring the peel strength for a combination of typically incompatible polymers, such as polypropylene and polyurethane (PP/TPU), demonstrated the efficiency of the plasma surface activation. The results show that the treatment time drastically increases material compatibility and the possibility of achieving high peel strength (i.e., above 12.5 N/mm).

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

How to Learn Mold Design Virtually

Plastics Engineering program instructors share their strategies for successful virtual learning for hands-on injection mold design.

Read MoreMMT Chats: Virtual R&D and Teaching Plastic Injection Mold Design

New Editorial Advisory Board member Davide Masato, an Assistant Professor at the University of Massachusetts Lowell, joined me for a 20-minute video chat about the importance of plastics engineering, and how COVID-19 changed the faculty's approach to teaching mold engineering and plastics research.

Read More2020-2023 Editorial Advisory Board: Meet New Board Member Davide Masato Ph.D.

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)