The mold manufacturing industry has hard shoes to fill, but the next-generation under the age of 30 is eager to try with grace and grit. From teacher assistants, apprentices and journeyman mold builders, to engineers, project managers and company owners, and everything in between, the crop of young professional talent from around the globe is breaking the mold, as they say. And these masters of moldmaking and mold design are equally eager to share their tribal knowledge and pass on that passion, which keeps this community advancing into the future.

Today’s blog features those Northeastern-based young professionals in the U.S. who are contributing to the advancement of the mold manufacturing community in a variety of ways. Read their stories below.

Northeast

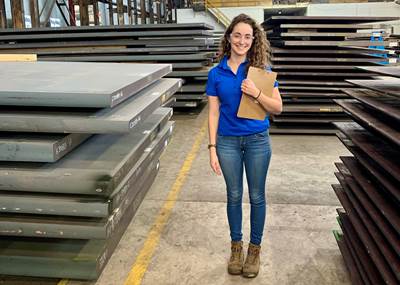

Katherine Pistorius, Project Engineer

After graduating from Penn State with a degree in industrial engineering, Katherine joined Edro as an apprentice learning the fundamentals of the specialty steel industry. Her strong ambition for future growth, good work ethic, interest in innovation and determination were evident immediately.

During her three years with the company, Katherine has shown outstanding leadership potential, excellent communication skills and the ability to apply herself to various tasks and projects focused on mold steel production, internal manufacturing processes and distribution activities.

Katherine is currently working in a project engineer role, tasked with leading several key lean projects on improvement and waste reduction. She completed her Six Sigma Green Belt qualification.

Michael Muthoka, Project Engineer

Michael Muthoka has shown outstanding leadership potential, excellent communication skills and the ability to apply himself impressively to the tasks and responsibilities he has fulfilled during his four years with Edro.

After graduating from Penn State University with a degree in metallurgy, Michael joined Edro as an apprentice and immediately received an introduction to the fundamentals of the specialty steel industry. In his early days of employment, Michael contributed to the company in a meaningful way, focusing on his main apprenticeship project—machining evaluation of plastic mold steels.

Today, Michael’s main responsibility is plate production, including conversion and heat treatment. He has quickly become the company’s main contact at our major supply chain partner steel plate mills, converting mold steel ingots to plate. He is also responsible for production scheduling to support the company’s global material distribution business and plate conversion scheduling.

Michael possesses ambition for future growth, development, innovation, a strong work ethic, enthusiasm and determination.

Rob McMaster, Process Engineer

Rob is a graduate of the Penn State University Plastics Program and earned the RJG master molder 1 and 2 titles. He interned at X-Cell in 2020 before starting full-time upon his graduation. Rob took advantage of a unique opportunity to gain in-depth knowledge of mold sampling and validation for newly constructed plastic injection molds, preparing him to be very successful and a major contributor to the future of the plastics industry.

X-Cell builds multi-cavity, high-precision molds with complex actions for the medical device, consumer product, electronic and automotive sectors. X-Cell also samples its molds before shipping. This work exposes Rob to different engineering and commodity resins and additives like foaming, slip and nucleating agents and colors (pellet and liquid). He has also learned about mold designs that include actions and functions such as slides, lifters, hydraulic core pull, collapsible cores, unscrewing tools, servo actions, two-shot, in-mold closing and hot runners (hot tip, valve gate and sequential valve gate).

Currently, Rob performs scientific injection molding to establish centerline processes and runs design of experiments (DoEs) and validation protocols based on customer needs. Rob uses injection molding technologies such as Roctool induction mold heating, iMFLUX process, Mold Vac vacuum systems and sequential valve gate systems during product development and prototyping. Rob also contributes in the production area when he is not sampling new molds. Rob’s ability to sample any tool design with any material has made him a true asset to the X-Cell team.

Rob also reaches out to the local community by working with the Penn State New Kensington COMETS STEM Program for middle school students to get exposure to industry and manufacturing. COMETS supports and guides middle school students, mostly young girls, to develop impressions of their abilities in science, engineering, math and technology. This program is a fun and exciting way for students to discover the career pathways available to them in these fields and promote diversity in STEM-related fields, education and careers.

Kyle Joseph, Design Engineer and Project Manager

Kyle Joseph has been a design engineer and program manager at Accede Mold & Tool since May 2018. He started after graduating from Gannon University with a Bachelor of Science degree in mechanical engineering.

He is currently managing 11 mold builds for the medical and consumer packaging industries, including multiple 24+24 stack molds and a 16+16 two-shot cube mold system. Customers are quick to praise Kyle for his excellent leadership and communication skills and steady project management style from design launch through mold install on their production floor.

Kyle embodies Accede’s culture of continuous improvement and moldmaking excellence. He is smart and conscientious, with strong attention to detail and a focus on quality. Kyle goes beyond his day-to-day responsibilities of mold design and project management. He is the internal champion and Accede representative for SPE while staying up-to-date on industry technology advancements and representing Accede at trade events.

Kyle can regularly be found on the shop floor, rolling up his sleeves to work side by side with experienced moldmakers, building and assembling the injection molds he designs. At just 25 years of age, Kyle’s competencies, initiative, drive and self-motivation are helping to make a difference in moldmaking as a leader and an innovator.

Micheal Belmont, Account Manager

Micheal Belmont has been at Westminster Tool since 2015 after receiving his degree in business administration from Sacred Heart University. He has contributed to our sales department's growth and increased his technical sales knowledge to better understand our customers' needs.

As the lead for quoting at Westminster Tool, Micheal is preparing 40 quotes on average each month and identifying potential projects. He has implemented major improvements to existing processes to deliver quotes to customers faster and begin projects sooner. For example, he developed a formal quoting checklist with a process-proven list of questions and parameters to address upfront with the customer.

He also developed “mini-processing” jobs, a practice that simulates all the production steps before any processing is performed, which reduced potential production delays and rework in the design phase and improved customer communication. Mini-processing goes through each step in the manufacturing process to predict production needs and mitigate potential risks. He has also been instrumental in improving the training and documentation for his role and our sales assistant position.

Micheal understands the importance of building relationships and takes personal accountability for every project he works on by prioritizing customer collaboration. He is constantly looking for ways to innovate and improve. As a result, he has emerged as an effective leader in the sales department and made a lasting impact on how our company builds, maintains and grows customer relationships.

Matt Lizotte, Wire EDM Lead

Matt finished his studies at Montachusett Regional Vocational Technical School and started at F&M three years ago after a few years working for another shop. During his first few days at F&M, he was disassembling and cleaning molds for repair jobs and then worked his way through CNC milling setups.

Matt trained alongside a skilled moldmaker in the wire EDM department, who then left the company. Matt stepped up and is now singlehandedly programming and running four wire EDMs—essentially the whole department. It is not unusual for Matt to clock in 55+ hours per week.

He also spearheaded the introduction of Esprit in the wire EDM department, significantly reducing programming time. Also, to keep the wire EDMs running, Matt learned how to program and run a Kellenberger cylindrical grinder.

The team believes our business could not exist in its current form without Matt’s initiative and abilities. We have one major customer who depends on F&M for its wire EDM capabilities, and all of that work goes through Matt. This is in addition to the standard mold-related wire work we have to do.

He is hardworking and conscientious, continually proving wrong the many stereotypes of today’s next-generation workers. If we could clone Matt, we would.

Hillary Thomas, Account Manager and Vice President

Hillary Thomas rejoined her family business at Westminster Tool in 2017 after working in international sales in Australia. Since returning, she successfully rebranded the company as a solutions-focused manufacturer and leader in cultural innovation. Her leadership extends to service on the American Mold Builders Association (AMBA, Indianapolis, Indiana) Emerging Leaders Board, PLASTICS FLiP Engagement Committee Society of Plastics Engineers and the (SPE, Brookfield, Connecticut) Foundation’s Marketing Committee.

Hillary has expanded her technical knowledge to serve her customers better and her abilities to drive strategic improvements in the company. Her goal is to sell a product and remain intimately involved in a project from beginning to end to be a better customer resource.

Her goal is to always set her team up for success. She accomplishes this by working closely with each employee on an individual level, by looking closely at sales and engineering goals and diligently tracking performance metrics to find areas for improvement. Hillary also has a natural talent for growing leaders within the company and providing them with the support needed to improve.

She is also always looking for ways to innovate and help the community and the industry. Her passion for people extends outside the company, where she sees the value of spreading awareness of manufacturing and its benefits to our community.

The transformations directed by Hillary’s leadership can be seen across the company. Her advancements in sales made a direct impact on company revenue and the type of complex work brought in. This has opened opportunities for investments in technology, equipment and talent development.

Jacob Arsenault, Moldmaker Apprentice

As a young professional in our apprenticeship program, Jacob has undoubtedly stepped up to the plate and excelled among his peers. He has filled a role at a young age (new high school graduate) that far exceeds the title of “apprentice.”

Jacob is very hands-on and adaptive. He contrives solutions to difficult problems, whether in day-to-day operations or more complex matters with machinery and/or tooling. His “street smarts” go along with his education in moldmaking, and he is willing to do anything and everything asked of him. His attitude shines in the shop, and he is far beyond his years when it comes to matters of respect, drive and willingness.

Jacob is referred to as “Little Denny,” which references a long-term, recently retired, first-ever employee and friend of Wepco Plastics. Denny’s shoes are hard to fill, and Jacob is learning to fill them with grace and grit.

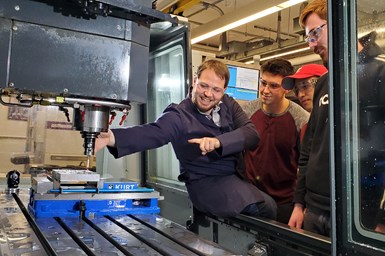

Michael Shone, Teaching Assistant, Ph.D. Candidate

Currently a Ph.D. student in the Department of Plastics Engineering at the University of Massachusetts Lowell, Mike has been providing invaluable contributions to undergraduate plastics engineering students' training and education in the area of moldmaking and engineering as a teaching assistant for plastics mold engineering.

Since taking the class as an undergraduate in 2014, Mike has helped faculty members by supporting the class with great passion and enthusiasm. In 2015 and 2016, he was an undergraduate teaching assistant, helping students with their mold designs, generating toolpaths, machining and molding. From 2017 until 2020, Mike stepped up as the lead teaching assistant, taking more responsibility for students’ project success. His expertise, leadership and devotion has helped 200+ students design, build and test their injection molds. Every year, his contributions make possible the realization of 8-10 injection molds from undergraduate students in just three months.

Through the years, Mike has mastered part/mold design, simulation, CAM, machining, polishing, assembly and molding. He has also created video tutorials to assist students with difficult concepts like CNC programming. Mike was awarded the Henry Thomas Design Excellence Award in 2016, Outstanding Teaching Assistant in 2018, and Russell Ehlers Processing Excellence Award in 2019.

Mike has also done extensive research on powder injection molding for an industrial sponsor as part of his Ph.D. work, which has resulted in the design and production of multiple research molds. While his research is still in progress, he presented his injection molding simulation work at the 2019 Moldflow Summit and the 2020 Connect conference, as well as his powder injection molding rheology work at the ANTEC 2018 and PPS 2018 conferences.

Patrick D-Antonio, Manufacturing Engineer

Seven years ago, Patrick was about to graduate high school and was looking for a summer job. YakAttack was small and in need of some extra help, so Patrick was hired. He quickly developed an affinity (and knack) for manufacturing, which has turned into an impressive career at the company.

After graduating high school, Ben pursued his four-year degree in mechanical engineering during which he split time between Old Dominion University and the shop floor. He earned his degree while spending the summers working on the manufacturing floor, and later as an intern in our the shop.

During his early years at YakAttack, Patrick loaded parts onto CNC routers and then learned programming. He started using various fixtures, then learned to design and build them. He helped to design and evolve the company’s manufacturing process.

Shortly after college graduation, Patrick went full-time at YakAttack, managing and streamlining the CNC routing operation. A year later, he turned his focus toward injection molding and moldmaking. Patrick helped to transform the company’s tooling art into a tooling process. Using his unique blend of creative and disciplined thinking, he refined and documented the company’s toolmaking process, making it comprehensible for a novice. He is currently training a young employee using the process that he was instrumental in creating.

Today, Patrick designs most of the molds and manages the tooling operation.

If you have a next-generation individual who you believe is worthy of some recognition for the grace and grit he/she displays while doing his/her job, nominate them here today for our continuing online coverage. We’ll review the entry and add them to our online 30 Under 30 Honors content.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)