Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts, and ancillary equipment.

ESSENTIAL READING

VIEW ALL5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MorePlastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

Read MoreHow to Prepare for the Rise of AM in Moldmaking

Mold builders should consider investing in three key areas to take advantage of the opportunities 3D printing presents.

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

WatchLatest Additive Manufacturing News And Updates

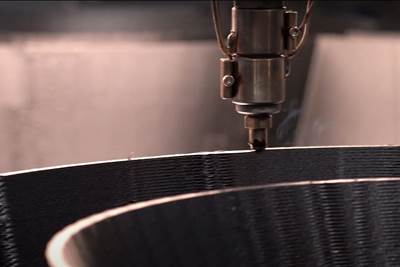

Hybrid Multitasking Five-Axis Brings Subtractive, Additive Processes to Moldmakers

Mazak’s VC-500A/5X vertical machining center delivers hybrid multitasking and hot wire deposition to meet machining and additive needs.

Read More3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

Read MoreMoldMaking Technology's Most-Viewed Case Studies of 2023

MoldMaking Technology’s case studies present a shop’s problem, solution and results in thorough detail. Take a look at our top five most-viewed case studies based on Google Analytics.

Read More3D Printing Tool Steels Reformulated for More Flexible, Less Brittle Filaments

Markforged has reformulated its H13 and D2 tool steel filaments for use with its Metal X 3D printing system.

Read MoreMoldMaking Technology's Hottest Tips of 2023

The staff at MoldMaking Technology prides ourselves on bringing you the most helpful, relevant tips in the industry. Here are the top five most-viewed tips of 2023 based on Google Analytics.

Read MoreMold Design Tricks, Additive Manufacturing Treats & More: MMT's Top-Viewed Articles in October

October held some tricks but mostly treats for MoldMaking Technology’s audience.

Read MoreFeatured Posts

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreDo You Remember?...The Best of MMT September

Say, do you remember? These top-viewed MMT articles from September?

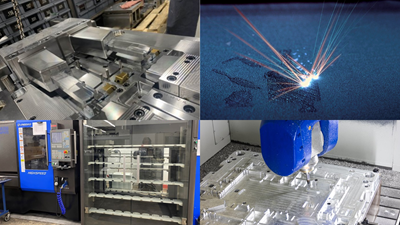

WatchThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MoreVIDEO: Why Is Sustainability Important to Mold Builders

Marta Orozco with DME shares ways mold builders can be a part of building a more sustainable future.

WatchVIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

WatchMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchFAQ: Additive Manufacturing

What are the use cases of additive manufacturing in moldmaking?

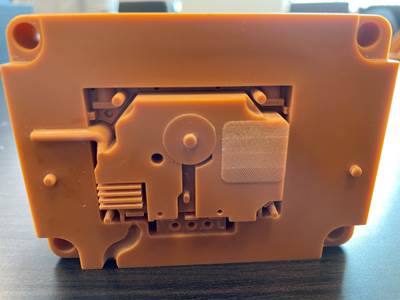

Additive manufacturing (AM) of metals is gaining market acceptance with specific use cases, including some workflow examples in moldmaking such as building up components with conformal cooling channels, printing expensive metals for less waste, or performing repair work to extend the life of production molds.

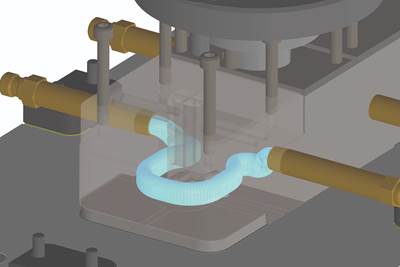

When it comes to the "big picture" view of AM, there are two approaches to moving the deposition head: flatbed (or planar) and multi-axis. Flatbed is the most common method used on printers ranging from inexpensive home 3D printers to large industrial metal laser sintering systems. When using the flatbed approach, parts are nested in a work envelope, and slicing is always planar—usually perpendicular to the Z-axis—and completed in that one direction.

The multi-axis approach deposits material in directions, compared to just one vector or direction. The print head of these systems is mounted inside a five-axis CNC machine or mounted onto a robot. They are referred to as hybrid multi-axis additive machines and can perform both additive and subtractive operations.

(Source: Five Key Aspects of a Basic Multi-Axis AM Programming Workflow and CAD/CAM/AM Tools)

Is additive manufacturing the same as 3D printing?

Some say yes and we say no! AM and 3D printing are overlapping terms but not synonyms. 3D printing is the operation at the heart of additive manufacturing, just as “turning” or “molding” might be the operation at the heart of a conventional manufacturing process.

In a nutshell, 3D printing is one step in an overall additive manufacturing workflow that also includes design, build preparation, postprocessing, business considerations and more.

Importantly, “3D printing” does not describe just one type of technology. Per ISO/ASTM, there are seven different “families” of 3D printing processes and a growing number of material and machine options.

Source: What is Additive Manufacturing?

Is 3D printing cost effective for moldmaking?

According to Matt Sand, president of 3DEO, a California-based metal AM parts supplier, there are three things to consider when determining whether it will be cost-effective to 3D print a given part:

1. Part Size

Is it bigger/smaller than a golf ball? One thing Sand has learned over the last few years is that as part size increases, the cost increases on an exponential curve.

Smaller (golf ball-sized) parts manufactured traditionally are price competitive. However, as the part size starts to reach softball size and greater, the cost skyrockets. It’s not uncommon in laser sintering for very large parts to cost $20,000 or more.

2. Assembly

Is the cost of assembly less than the cost of printing a consolidated part? Sand believes there is often a disconnect from reality when it comes to parts consolidation. “For example, a customer wants a five-piece automotive assembly printed as one piece. What they typically overlook is that the cost of the individual components and assembly is still very low,” he says. “The total cost of the metal 3D-printed part needs to be less than the total cost of the assembly. Given consolidated assemblies are large, it’s usually much more expensive to print versus assemble.”

3. Complexity

Does the part have complex features like conformal cooling, and is it likely to require substantial postprocessing? Conformal cooling is a hot trend in additive manufacturing, but 3DEO tries to be realistic with interested customers. The reality is that high-value tools are the best fit, because when it comes to laser sintering (the most common method used to make conformal cooling channels) the cost is high and the after-print surface finish still needs postprocessing.

(Source: When Is 3D Printing Cost Effective?)

How do moldmakers determine the quality of a plastic injection mold when 3D printing?

Here are two critical factors for determining the quality of a plastic injection mold and how AM fits into the mold build process to help meet and exceed these quality standards:

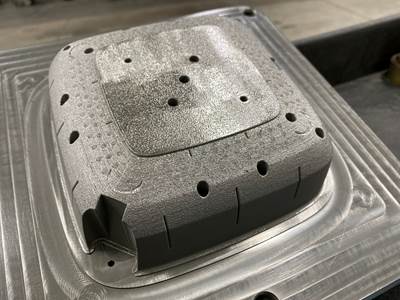

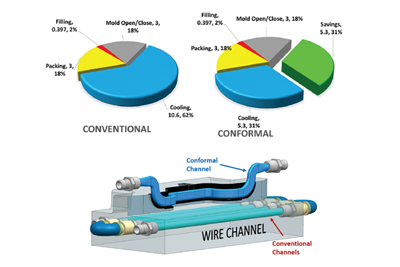

1. The mold's ability to quickly and consistently produce quality parts in conjunction with conformal cooling.

AM involves designing conformal cooling channels, unlike anything that a shop can produce with subtractive machining. Using AM, a mold builder can design conformal cooling channels that hug the contour of the part surface, eliminating hot and cool spots in the parts and reducing the risk of distortion. On top of that, using computer simulation software simplifies identifying the proper location for the cooling lines.

Removing the heat from the mold as quickly as possible is the key to reducing the amount of time the part must remain in the mold. Cooling line placement is one part of the equation. The other part is the steel’s ability to cool the mold, also known as thermal conductivity. Several mold material producers offer materials with high thermal conductivity (HTC).

2. The mold's strength and toughness at elevated temperatures.

This determines how long the mold will be able to run before downtime for maintenance is necessary. Strength goes together with hardness, which is determined primarily by the carbon content. However, high carbon content is where printability becomes an issue because higher carbon content can lead to cracking, reducing mold life.

AM is a combination of melting and heat treating that is impossible in traditional wrought operations. For example, laser powder bed fusion (L-PBF) is an AM process for building molds. It is a series of layer-by-layer melting of powder via a laser with subsequent gas cooling. Phase transformation occurs in this cooling, which, if not controlled, can lead to cracking.

However, today there are newly developed AM materials designed to reduce the carbon content, which prevents cracking but maintains acceptable mold hardenability. The toughness of these new AM materials is proving superior to the conventional material at the same hardness, which results from superior melting and processing to produce the powder and the subsequential microstructure available for AM parts.

(Source: Exploring AM Powders for Tooling)

How do moldmakers use hybrid additive manufacturing?

A hybrid AM part is a traditionally manufactured base geometry upon which material is added using various additive technologies. A common AM application in moldmaking is repairing old or worn molds—building up worn areas of a mold or adding new features to an old mold.

Different AM processes provide benefits to these applications. For example, directed energy deposition (DED) makes sense for most repair applications that need to build material back up. Powder bed fusion (PBF) is better suited for adding new features to an old mold, such as cooling channels or venting.

Most DED technologies follow the mold’s 3D surface, adding consistent, even layers to the worn areas of the mold, providing a more controlled heat affected zone (HAZ). Shops can then machine these areas back to the required shape, dimensions and tolerances.

The most common DED systems used in mold repair include a DED laser head and powder/wire delivery system built into a CNC system. This setup streamlines the process by requiring the shop to set up the worn mold in the system once, machine the rebuilt surfaces to yield a clean, even surface and then add material to build up these regions before final machining.

(Source: How to Use Hybrid Additive Manufacturing)

How can moldmakers improve 3D-printed conformal-cooled mold insert performance?

3D-printed molds with conformal cooling channels yield more efficient heat transfer, but the geometrically intricate channels may increase the likelihood of scaling. Scaling decreases flow and worsens the integrity of the cooling channel walls, which leads to leaking.

Maintenance solutions for eliminating scaling and corrosion range from cooling channels flushing with aggressive cleaning media that can damage the mold, to gentler ultrasonic cleaning that may be ineffective. Shops also opt to fix leaking cooling channels, which has high costs and downtime, and, in many cases, is not possible.

Another option for combating scaling and corrosion is to coat the inner diameter of the cooling channels. Most mold builders and parts manufacturers are familiar with electroplating or PVD coating mold surfaces to increase hardness and to extend mold life, but many do not realize that a surface treatment to the inner cooling channels will improve the lifespan of a mold’s interior as well.

Applying a thin layer of internal, ultra-thin, thermally conductive ceramic coating can provide several benefits that ultimately prolong the lifespan of the cooling channels, provide better uptime and save an injection molder money. The coating is thin enough (50-100 microns) that it has no measurable effect on heat transfer.

(Source: How to Improve 3D-Printed Conformal-Cooled Mold Insert Performance)

How does a moldmaker choose the right cutter for hybrid additive manufacturing?

Four ways to apply the right cutting tools in hybrid additive manufacturing are:

- Ball-nose and radius end mills with a special neck design, cutting edge contour and coating are good choices. A pre-milling end mill with ball-nose geometry targets roughing and pre-finishing operations in order to produce a specific machining allowance on the additively manufactured component. The machining direction here is from top (Z+) to bottom (Z-).

- A finishing cutter, also with ball-nose geometry, is recommended for finishing operations in construction layers no longer subject to thermal stress. The cutting area of the tool should be designed so that pull machining from bottom (Z-) to top (Z+) is possible in order to finish the material layers that are no longer thermally stressed.

- A "back taper" radius end mill is suitable for 2D machining of undercuts on the component. Its specifications are aimed at pre-finishing and finishing applications on additively produced components.

- Some hybrid additive manufacturing applications may require solid carbide micro end mills that are designed to meet the unique and demanding requirements of micro machining applications. In this case, micro end mills with a specific neck geometry enable the optimal application of these tools even in deep contours. A high radial bending strength allow the tools to withstand alternating radial stress on the cutting edge and on the relieved neck during the machining process. A newly developed ALCR coating provided exceptional wear resistance for long tool life.

(Source: Cutter Considerations for Hybrid Additive Manufacturing

How does a moldmaker know which 3D printing technology to use?

With AM, it is possible to address a wide range of moldmaking needs from printing entire molds or inserts (often with powder bed fusion/PBF or vat photopolymerization) to localized repair or hardface welding of mold surfaces (often with directed energy deposition/DED). In moldmaking, these use cases ultimately translate into improvements to lead time, cycle time and lifetime.

(Source: The Mold Builder’s Guide to Additive Manufacturing & Hybrid Manufacturing Technologies)

What is Formnext Chicago?

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois.

Formnext Chicago is part of a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

Here is the full lineup of Formnext events in North America:

- Formnext Forum Austin took place in August 2023 and will return to Texas in 2026.

- Additive Manufacturing Sector Powered by Formnext at IMTS in 2024

- Formnext Chicago in 2025

.jpg;maxWidth=300;quality=90)