Jig Grinder for Mold and Die Increases Rigidity for High Precision

The Hardinge Hauser 2000 combines grinding and hard milling features under one machine, featuring a dual-frame design, elimination of transverse forces and more to ensure highly accurate machining capabilities.

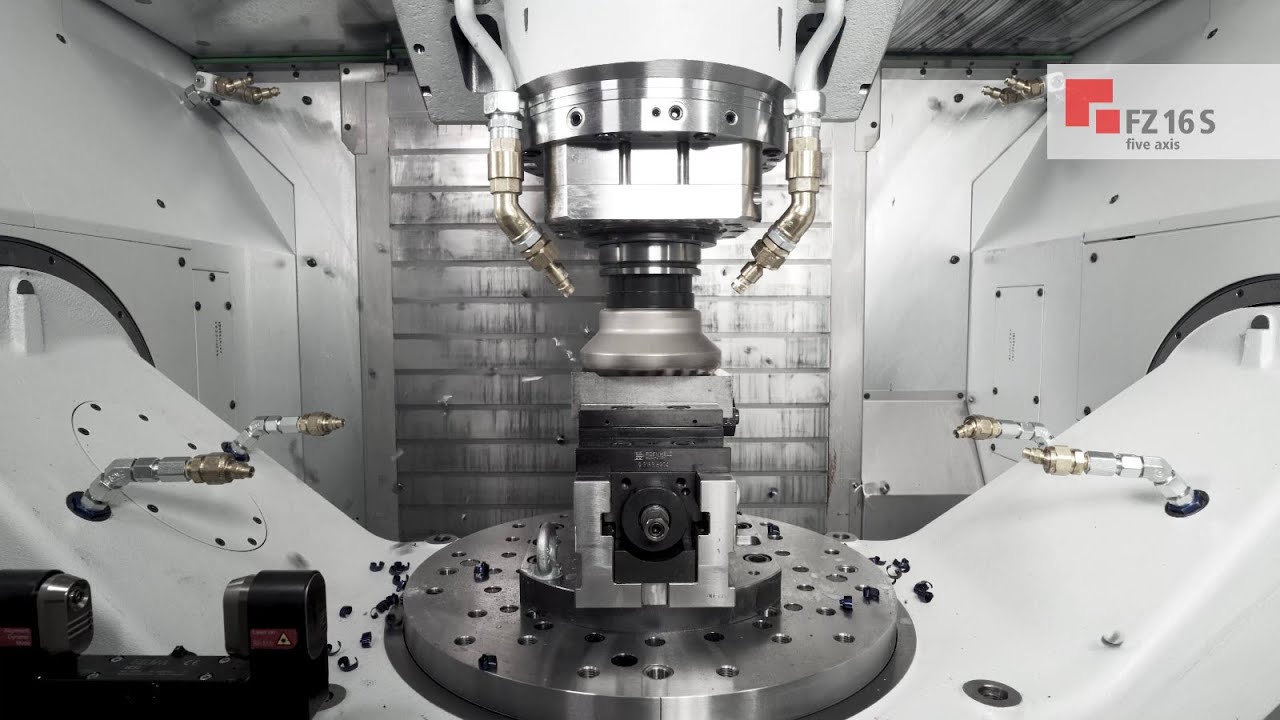

Machining Center Provides Robust, Dynamic Milling Qualities

Roughing and finishing deep mold and die cavities is optimized using Chiron’s FZ 16 S five-axis machining center equipped with an HSK-A 100 interface, enabling reduced chatter, dynamic machining and the ability to tackle difficult materials.

#fiveaxis

Five-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

#fiveaxis #casestudy

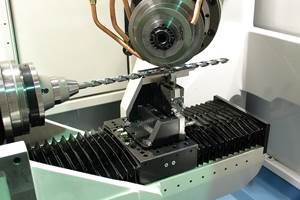

How to Overcome Common Deep-Hole Drilling Challenges

Producing deep holes effectively and efficiently is a challenging application that requires cutting tool solutions that offer predictable cutter life, accurate surface finish and repeatability.

#Tips

Customizable Pallet Storage System Enables Unmanned Machining Operations

Especially well-suited for smaller shops, Grob Systems’ flexible PSS-T300 enables automatic pallet loading and removal for increased part production throughput.

Five-Axis Machine Expands Advantages for Moldmaking

Optimized tool path and cutting angle control, access to hard-to-reach surfaces and overall efficiency and precision make Expand Machinery’s Gen Mill 5X-24 machining center optimal for the mold and die industry.

#fiveaxis

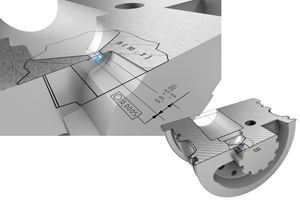

How to Cut Setup Time, Extend Gate Life With the Right Machining Strategy

Microcut honing provides high-precision machining of needle valve nozzles and guides in hot runner systems.

Technology and Sourcing Guide 2023: Machining

Machining shapes metal workpieces. Understanding both traditional and advanced machining techniques is critical to overcoming the various dimensional and finish challenges.

Easy-to-Use CNC Control With Redesigned Graphical Interface

Kitaumura’s Arumatik-Mi control system, featuring a revamped, modern GUI, simplifies programming, part setup and machining for operators of all skill levels.

Face Mill Holder With Damping Vibration Control Supports Far-Reaching Operations

Big Kaiser, a member of the Big Daishowa Group, offers the new SDF57 arbor-style face mill holders, what it claims is the largest and longest milling tool, which could have important benefits for moldmakers.

#Workholding