HTS International Optimizes Conformal Cooling with iTherm Technology

Amerimold 2021 exhibitor HTS introduces iTherm for injection molds, which can be integrated through any toolshop with various options for manufacture.

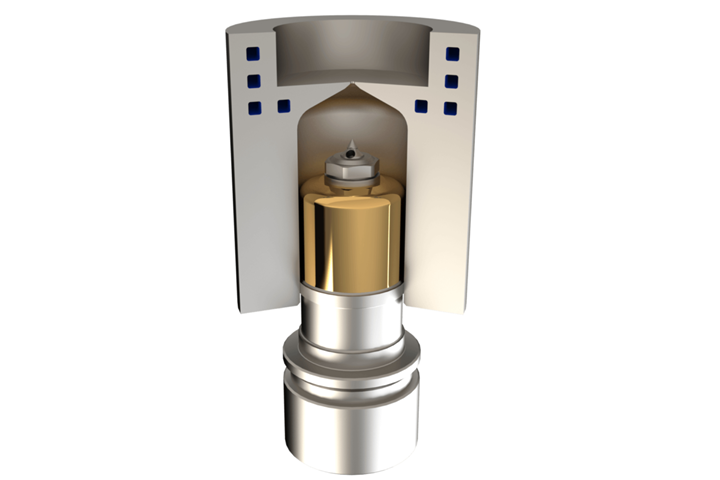

Photo Credit: HTS

HTS iTherm, which can be integrated through any toolshop, with various options for manufacture, offers conformal cooling for injection molds, improving the ability to cool challenging inserts and cores, and often reducing cycle time or improving part quality. Material options include H13, 420SS and other standard tool steels.

Example components will be on display at Amerimold this September, where attendees can consult with expert engineering staff about design solutions for improving their tooling.

Exhibitor: HTS International Corp.

Booth M-929

Related Content

-

Moldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

-

VIDEO: Explaining MoldMaking Versus Mold Manufacturing

To understand how training has been impacted we first need to understand the differences between a few key concepts. What is moldmaking vs. mold manufacturing? Who is a mold designer vs. a mold engineer?

-

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.