When Great Plastic Products Fail

Not too long ago I blogged about how moldmakers are often approached by entrepreneurial types with no manufacturing background about building molds for new product “inventions”. I also touched on the fact that many moldmakers themselves invent things, and I requested personal stories from readers. This is about a great product that didn’t do so great.

The True Quiet Treestand was designed and developed by a tooling engineer and his brother. While the product met all standards for safety and was well-received, customers could not get past the past.

Not too long ago I blogged about how moldmakers are often approached by entrepreneurial types with no manufacturing background about building molds for new product “inventions”. I also touched on the fact that many moldmakers themselves invent things, and I requested personal stories from readers. This is about a great product that didn’t do so great.

Robert Cianfrocco, who, over the course of 45 years, has worked as a process engineer, project engineer and tooling engineer, emailed me about a product he and his brother designed and developed: The True Quiet Treestand.

Robert explained how the tree stand was designed to be all plastic versus the traditional metal material, and that it would be used to hunt whitetail deer. Both brothers made significant financial investments into the project.

“Having been in the industry all my life, I knew what to expect regarding tooling and processing and the relative costs associated with bringing the product to market,” he explains. “We had the five parts drawn up in CAD by a friend of mine. We successfully built the tooling and the product passed testing requirements set by the Treestand Manufacturers Association, which included its ability to hold one-and-a-half times the weight that we stated in our literature it could hold. In this case, we said it would hold up to 300 pounds, when in reality it passed tests for holding up to 450 pounds.”

Once the certification was awarded, it was time to try selling the product to the big box stores and promoting it at trade shows.

“Everyone loved it, but in the back of their minds was always the fear of sitting 20 feet off the ground on a piece of plastic,” Robert says. “The stigma created by plastic products that were not designed properly or were not made from the right plastics materials back in the 1960s and 1970s and failed—that stigma never passed the test of confidence.”

Robert and his brother put five years into the True Quiet Treestand, and they were even able to price it competitively and guaranteed it for life, but to no avail.

“We all remember the plastic forks and spoons that broke when we pushed down on our food with them,” he says. “We all had that radio that broke when we dropped it back in the late 60’s or early 70’s. Things have changed regarding plastics but some people just didn’t!”

Despite the outcome, Robert says his brother has not lost heart and has been working on yet another new product that he hopes to bring to market soon. As for Robert, he is content with his work as principal engineer for a major medical OEM.

Thank you, Robert, for sharing your story. I hope more MMT readers will share their experiences. If you have a story, please email me and maybe I’ll blog about it.

Related Content

MMT Chats: Applying Bench Lessons to the Business of Moldmaking

For this MMT Chat, my guest is Mark Gauvain, one of MMT’s newer Editorial Advisory Board members who has plenty to share as he recently made the move from working for some big manufacturers to working for himself as a consultant to moldmakers and molders on procurement and technology investment strategies.

Read MoreHammonton Mold, ADOP France Forge Strategic Partnership in Injection Blow Moldmaking

Hammonton Mold Inc., a leading full-service mold shop based in New Jersey specializing in injection blow molds (IBM), proudly announces its official partnership with ADOP France, a prominent IBM mold manufacturer based in Normandy, France.

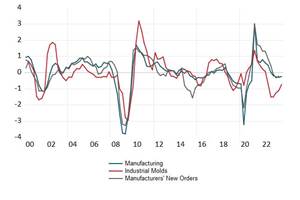

Read MoreNavigating Economic Resilience and Consumer Trends

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)