Western Carolina Tool & Mold (WCTM) is a full-service mold shop, specializing in plastic injection molds weighing less than 10,000 pounds, with a focus on intricate and high-quality designs. Source (All Images) | Western Carolina Tool & Mold

Who is Western Carolina Tool & Mold?

Gabe English, president, Western Carolina Tool & Mold (WCTM): Western Carolina Tool & Mold (WCTM) was founded in 1997 by five partners, each bringing distinct skills to the table: shop management, design, welding, toolmaking and die-making. They worked together at Alliance-Carolina and then decided to launch WCTM. These partners, who remain close friends, have been invaluable mentors to both my wife, Holly, and me.

WCTM designed and constructed about 35 new molds and completed more than 600 engineering changes and repairs in 2023.

Today, WCTM operates as a full-service tool and mold shop, specializing in plastic injection molds weighing less than 10,000 pounds, with a focus on intricate and high-quality designs. Our projects range from engineering changes to complex designs. Our guiding principle is to design and build tools with the end user in mind, ensuring they are easy to work with and maintain. Quality and reliability are paramount in our products. In 2023, we designed and constructed approximately 35 new molds and completed more than 600 engineering changes and repairs.

Share your journey from the shop floor to ownership.

English: I graduated from Blue Ridge Community College with a machining technology degree in 1999 and completed an 8,000-hour North Carolina State Apprenticeship at Alliance-Carolina Tool and Mold. I have gained experience in programming various equipment, including wire and sinker EDMs, high-speed, four-axis gundrill machines and electrode-cutting machines. I have also worked in engineering, focusing on mold design and engineering changes. In 2006, just six years into my career, I took over as shop foreman.

After leaving Alliance-Carolina in 2007, I joined A&M Tool as the shop foreman. Besides managing the shop, I was responsible for various aspects of the business, such as engineering, quoting and project management. I had the opportunity to work with a talented management team and a skilled group of toolmakers, whom I still consider friends to this day and with whom I often share overflow work.

In 2017, I became the production manager at Daystar Machining, a 50-person production shop. This experience allowed me to learn all aspects of the business, which I consider a 20-year test drive before taking ownership at WCTM. In 2018, Danny Grant, one of WCTM’s partners, approached me about buying the company. I started the process, and we closed the deal in May 2020. Since then, we have doubled sales and maintained around 17 employees.

How did you manage the transition to ownership, and what were your key moves?

English: One of the most important tools for our business has been the E2 ERP shop software. We integrated E2 before I purchased the business, but I’ve made it a priority to capitalize on its capabilities. Before E2, we used Excel spreadsheets, which didn’t allow us to track costs or profit/loss accurately. Additionally, the entire system relied on one person.

I recognized the need to implement a user-friendly system to enforce organization into the process. My friend, Jaime Hare, helped us convert the office to E2 and QuickBooks, which streamlined everything! Jaime is a testament to the old saying, “You don’t have to know everything. You need to know someone who does!”

WCTM plans to upgrade its graphite mill for electrode manufacturing to improve its capabilities and efficiency for projects with tighter tolerances.

I also focused on strategically rearranging the shopfloor layout. When the team moved into the new facility in 2003, there was very little equipment in comparison to the size of the shop, and as new machines were purchased over the years, they were placed wherever there was an open spot. I moved all the equipment to the walls to open up the aisles and organized them into groups by equipment type to minimize movement and increase the space to load machines with forklifts when needed.

The old layout also used a central tool crib, which I decided to split up to enable several simple movements instead. For example, I put anything used in assembly — such as screws, O-rings, water fittings and grease — in the assembly area, and cutting tools like drills, reamers and end mills close to the milling department. We also installed a matrix machine that Southwest Tool Supply keeps stocked with all of our specialty cutters. This gives us access to cutting tools on-site for emergency jobs and cuts down on the cost of frequently overnighting end mills. I estimate this to have saved approximately $5,000 per year in overnight shipping charges for cutting tools.

The largest impact of the Makino PS105 VMC is its deep-hole drilling through-spindle coolant capabilities and its high-torque spindle for heavy material removal.

I also invested in new equipment. My first purchase was a Makino F5 vertical machining center because we needed a reliable and accurate machine, and I have a history with Makino. Their service is second to none, and this machine runs lights-out a large portion of the time. We also invested in a Makino PS105 vertical machining center to help with roughing, pre-heat treat and finishing. The biggest impact of this machine is its deep-hole drilling through-spindle coolant capabilities and its high-torque spindle for heavy material removal. The Mitsubishi EA12 sinker EDM helps us burn faster and more accurately, and our Micro-Vu inspection system allows us to measure some of the finer details of our work.

I aim to maintain a balance between innovation and maintaining our core competencies. I also decided to diversify the customer base, with an emphasis on reducing dependence on the automotive sector, but I remain open to automotive work, provided it aligns with our vision. Today, we serve a range of industries, including medical, textile, packaging and food-grade products.

The previous owners mainly did repairs and engineering changes. My vision is to reduce the number of rough repair jobs and concentrate more on higher-end engineering changes and target new mold builds. This aligns better with the skill set of the newer employees.

It was a little scary turning work away, but this focus on work that aligns more with our skills and capabilities has paid off. I have had conversations with key customers who have given us more steady work. We noticed that in the first year, our gross sales didn’t change much, but our profitability increased greatly. In the past year and a half, we have seen our gross sales jump, and I attribute that to the trust we have established with our customers.

One example of that trust is Alltrista Plastics in Greer, South Carolina. Program manager Ryan Bubb shared this nice testimonial: “The team at Western Carolina Tool is a mold vendor that I can always count on. They are experts in finding solutions to any issues we have encountered. They are not happy until we are happy. They stand behind their work. They always go the extra mile to meet our agreed-upon timelines and ensure that we have good tools to run the high-end products that we produce at Alltrista Plastics. The partnership is incredible, and they are a company that I can always trust.”

I'm dedicated to exposing the younger generation to the rewarding career opportunities that the mold manufacturing industry offers, especially for those who may not thrive in traditional educational settings like myself.

Can you tell me about the role family, particularly your wife, played in your journey?

English: My wife has been an incredible support. She was an elementary school teacher with a solid educational background and her organizational and business skills have been immensely beneficial to us. She manages various aspects of the business, such as accounting, benefits and insurance. Our partnership is great; it balances her book smarts with my street smarts.

Gabe and Holly English combine her book smarts and his street smarts to grow WCTM.

Holly taught elementary school for 16 years before joining us full-time in May 2020. She initially pursued a degree in business but switched to a BS in Elementary Education halfway through. Her organizational skills are her strong suit, as she is far more organized than I am! The greatest advantage of her managing everything is the trust I have in her. She even gives our two daughters jobs during the summer and after school, holding them accountable. Having my wife and kids here at work is truly wonderful.

How did you go about recruiting the right team when you needed to hire new employees?

English: Since taking over the business, I've worked to maintain WCTM’s positive culture, which is rooted in teamwork, unity and collaborative decision-making. While I oversee the business and investment strategies, I highly value the input and expertise of our team.

Since taking over the business, Gabe English has focused on maintaining WCTM's positive culture, which is rooted in teamwork, unity and collaborative decision-making.

Finding suitable replacements hasn’t been easy. When I took charge, I had to sift through approximately 12 candidates to fill five positions. One of the challenges we faced was the shift in the average age of our workforce. Previously, the average age was around 57, but now it’s closer to 44. I believe in providing opportunities to young and skilled individuals, even if they lack formal education.

I’m dedicated to exposing the younger generation to the rewarding career opportunities that the mold manufacturing industry offers, especially for those who may not thrive in traditional educational settings like myself.

We’ve had a high school senior intern in design working with us, dedicating four hours per day as part of a CTE class. Every spring, I participate in a career day at Blue Ridge Community College, where all high school juniors from the county explore the classes offered at the school. If we hire them as apprentices, we cover tuition, books and up to 10 hours per week of wages for employees while attending classes. We’ve already had one young man graduate with an associate’s degree and our second will graduate this fall. Providing these opportunities is a great blessing to us, as our employees are incredibly important to us, both personally and professionally.

Without the opportunities the trade has provided me, I would not have achieved what I have in my career so far. My journey from struggling in school to owning a home and having a retirement plan is a testament to the trade’s ability to offer a better life to those with talent and dedication.

Our projects often require innovative solutions to simplify the manufacturing process and reduce costs for our customers.

Can you provide some examples of the complex or intricate work you’ve done?

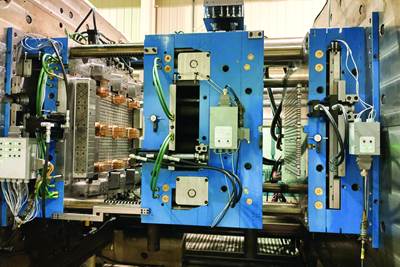

This innovative automotive part design features a four-cavity mold with internal cores and a dovetail system.

English: We have taken on projects involving molds for vehicle parts and for molding complex parts with buried cores and intricate actions. For example:

- Automotive part: We designed a four-cavity mold with internal cores and a dovetail system for core release. This project showcased our ability to solve complex problems. We created small cores that had to open and close with the parting line in the shut position, which was necessary due to critical dimensions and a lack of draft on the surfaces where they shut off.

- Bracket mold: We also built a bracket mold with an internally retracting core pin. In our mold designs, we strive to incorporate as many off-the-shelf items as possible so that customers can replace them more quickly and inexpensively in the future. For this mold, we used Progressive slide units for the external slides and constructed the internal core actions around PCS TLB series trunnions.

Our projects often require innovative solutions to simplify the manufacturing process and reduce costs for our customers.

Speaking of working with customers, you deal with both molders and OEMs. How do their expectations and working relationships differ?

English: Molders often exhibit a more flexible and practical approach, facilitating direct and honest conversations. They must balance internal standards with OEM requirements. In contrast, OEMs can be more departmentalized, making it challenging to obtain direct answers due to team specialization. Nevertheless, we adapt our approach based on our customers’ needs and expectations. For instance, when interacting with customers, they communicate directly with our general manager, Jason Frank or me. We are not middlemen; Jason and I are direct links to the shop.

We believe that strong relationships are pivotal to the business’ success. Many of our existing customers have been with Western Carolina for over two decades, underscoring the significance of reliability and trust. Our sales approach is personal and collaborative, grounded in trust and mutual respect. Our team prioritizes a personal touch, striving to establish a reputation for quality and service that customers will remember.

Do you have any future plans that you want to share?

English: Currently, we are on track to expand the facility and introduce more automation. New machines have already been installed and the expansion plans will improve material flow, enhancing overall efficiency.

WCTM’s Mitsubishi sinker EDMs help the team burn faster and more accurately.

Over the next five years, we plan to upgrade our graphite mill to support electrode manufacturing. This upgrade will boost our capabilities and efficiency for projects with tighter tolerances, which we believe is a strategic move to maintain competitiveness.

Additionally, we are considering acquiring a smaller, multipurpose three-axis mill for roughing and detail work, along with a Makino horizontal machining center. Our experiences with Makino and Mitsubishi machines have been impressive in terms of both service and performance, placing them at the top of our list. I have personal relationships with both companies, stemming from my time at Alliance-Carolina.

We are also actively cultivating stronger relationships with customers, prioritizing partnerships over transactions. My long-term vision is to establish Western Carolina Tool & Mold as a highly respected, reliable partner for manufacturers in various industries.

I have set a goal to visit at least one customer per month to maintain contact and discuss how we can support them. I believe face-to-face interactions are more effective than phone calls. Additionally, we strive to exceed expectations by providing detailed inspection information and photos. It’s remarkable how much such small gestures can mean to a customer, such as offering before-and-after measurements on changes, whether requested or not.

Related Content

Design Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreNon-profit Organization Advances Diversity and Inclusion Initiatives in Manufacturing to Fill Skills Gap

Build A Dream delivers programs to inspire young women, providing confidence and filling the skills gap by collaborating with speakers, community leaders and businesses.

Read MoreSmall, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreRead Next

A Passion for Innovation in High-Precision, Multi-Cavity Moldmaking

Boucherie uses its dedicated R&D facility to develop new mold, machinery and automation technologies to stay ahead of the competition.

Read MoreHigh-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read MoreBalancing People, Process and Technology for Program Management Success

Using the expertise of its team members and emphasizing efficiency, this Michigan mold builder's process is designed to function as a highly efficient system.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)