Hot Runners

Hot Runner System Demonstrates More Precise Melt Control

NPE2024: Husky Technologies debuts the Ultrashot injection molding system, designed to increase overall part design freedom with high scale and quality.

Read MoreCustomizable Hot Runner Controllers Range

NPE2024: Athena Controls highlights five controllers that provide features or enhancements for increasingly precise hot runner temperature regulation.

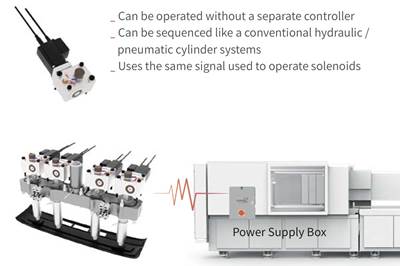

Read MoreElectric Servo Cylinder Enables Detailed Valve Pin Control, Energy Efficiency

NPE2024: Yudo USA features Yu Drive II Eco, a compact solution that doesn’t require a separate controller, operating only by combining injection machine signals.

Read MoreMini Hot Runner Nozzle Supports Intricate Geometries, Complex Parts

NPE2024: The Star Line Crown Mini, offered through Technoject Machinery, provides edge gate technology in a small package.

Read More3D Printed Hot Runner Nozzles, Pressure Pads Provide Reliable Temperature Handling

NPE2024: Witosa GmbH, through its distributor DMS, brings the Monolith hot runner nozzle and hardened steel Energy Blocker to the U.S., enabling the reduction in time, costs and improvements in product quality.

Read MoreHot Runner Controller Made to Integrate Into Molding Machines

NPE2024: The MOD24, by Fast Heat by Spark Industries, gives mold builders and toolrooms unlimited plug and play while combining the benefits of independent and integrated hot runner controls.

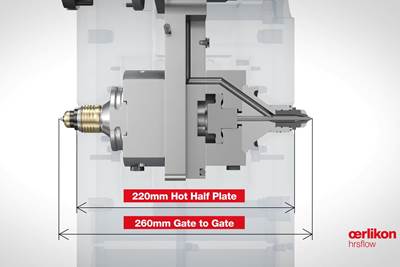

Read MoreStack Mold System Combines Fast Injection With High Process Repeatability

NPE2024: Primarily designed for thin-wall packaging applications, the patent-pending mold design by Oerlikon HRSflow brings consistency, simplified maintenance and assembly and a sustainable materials focus.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLSR Platform Meets Critical Medical Molding Needs

NPE2024: Recent updates to Mastip’s Aquilo platform highlight how its design — from consistent thermal profile to uniform cooling — has made it successful for medical industry projects.

Read MoreMoldmaking, Plastics Innovations Designed to Boost Injection Molding, Streamline Operations

NPE2024: PCS Company introduces several new products, including the MCS system, hot runner alarm systems, sprue bushings, a micro-TIG welder and its full Smartflow product line.

Read More

.jpg;maxWidth=300;quality=90)