Preform Mold Technology Increases Flexibility, Reduces Cost

A flexible and cost-effective PET system featuring modular, low cavitation PET preform molds reduces both conversion costs and mold changeover time.

A flexible and cost-effective PET system featuring modular, low cavitation PET preform molds reduces both conversion costs and mold changeover time.

Unveiled at Chinaplas 2008 by Husky Injection Molding Systems Ltd. (Bolton, ON)—a worldwide supplier of injection molding equipment and services to the plastics industry—Flex Mold is ideal for preform and bottle producers using one machine for multiple applications, that must be able to change molds with minimal downtime. It also benefits manufacturers that produce a range of preforms with the same neck finish, but for different sized applications.

Meeting Customer Needs

The introduction of Flex Mold will allow Husky to meet the needs of lower volume, custom preform and bottle producers, particularly those producing between five to 30 million units each year, according to Laurent Sigler, Husky’s Business Manager New Technology. “The technology also is helping converters expand into new markets because they can now pursue niche or developmental projects that were previously not financially feasible,” Sigler explains. “After talking to potential customers in this market segment, we realized that cycle time was not the number-one driver for these applications. Flexibility, ease of use and lower conversion costs are what customers need.”

How It Works

This system’s modular design provides many benefits during conversion, Sigler explains. “The mold’s unique design eliminates the need to cool down and reheat the hot runner during a part changeover, which greatly reduces system downtime. It also cuts cost by minimizing the number of components to be replaced while easily accommodating any preform length. Change times can be reduced to as little as a third of the time it takes to switch a conventional mold.

| Chart 1 | ||

| Changeover Task |

Time Required* (min.)

Standard Mold |

Time Required* (min.)

Flex Mold |

| Cool and heat hot runner |

40

|

0

|

| Change cavity plate |

30

|

15

|

| Change push-pull pads |

20

|

5

|

| Change moving half |

30

|

15

|

| Takeout plate assembly |

60

|

15

|

| Water and air connections |

30

|

10

|

| TOTAL |

210

|

60

|

| *assumes one skilled operator, working alone | ||

| Faster changeover times and low tooling costs. Chart courtesy of Husky. | ||

“The simplified design means that only a portion of the cavity must be replaced for a conversion, since the gate pads remain on the hot runner,” Sigler continues. “Instead of replacing the ejection cams (preform design related) with a conventional mold approach, Flex Mold uses a new concept of adjustable stroke cams that save both time and money.”

On the take-off plate side, the main plate remains in the machine and the cooling tubes are removed in individual rows called take-off bars. This eliminates the time and effort required to align the take-off and CoolPik plates for each removal.

The system is available in eight, 16 or 24 cavities, which will accommodate preforms with threads having a maximum diameter of 63mm, 43mm and 30mm, respectively.

“Advantages of the new systems are numerous,” Sigler concludes. “It offers uncomplicated solutions with a simple cavity lock stack design and adjustable ejection cams. Quicker mold changes are possible because the hot runner and take-off plate remain inside the machine and the same CoolPik plate and pins are used for most preforms. The mold water purge system is built into the machine and each mold half includes one water in and one out—which also saves time.”

Related Content

Precision Custom Core Pins

Smith Enterprises highlights its wide range of custom core pins for high-cavitation molds.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreAdvancing the Mold With New Technologies

This roundup is full of products and services that help answer concerns and meet needs for the industry. Featured in this roundup are hot runners, mold components, mold materials and more.

Read MoreEjector Pin Selection Guide

A review of materials, treatments and coatings to help determine the proper pins for optimized plastic part ejection.

Read MoreRead Next

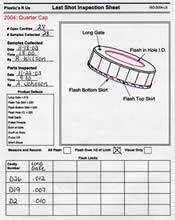

Across the Bench - Creating a Repair Plan

The last shot is the most important key to insuring accurate mold repair.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)