What Do You Really Know about Mold Cooling?

Do you ever ask yourself why cycle time matters? Although the level of impact may vary across the supply chain, one thing is certain: reducing cycle times can lead to hidden cost savings. And with cooling and recovery making up more than 80 percent of the injection molding cycle, it is the perfect place for improvement to help reduce cycle times. Listen to this webinar to learn how to achieve optimal cooling through analysis.

#analysis

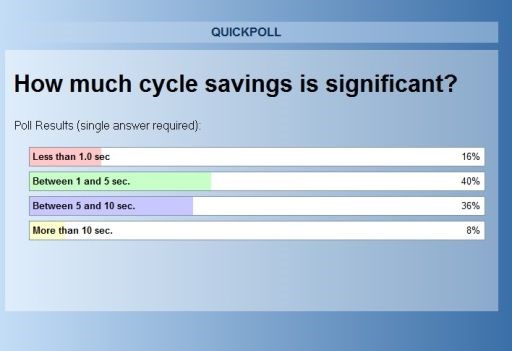

Do you ever ask yourself why cycle time matters? Although the level of impact may vary across the supply chain, one thing is certain: reducing cycle times can lead to hidden cost savings, such as required production quantities being reached sooner, machines opening up, avoiding capacity tooling, avoiding machine purchases and avoiding plant build-outs. And with cooling and recovery making up 80 percent of the injection molding cycle, it is the perfect place for improvement to help reduce cycle times. The key to this improvement is using analysis. Listen to this archived webinar to learn how to achieve optimal cooling through analysis.

Tim Lankisch from CAE Services explains how cooling analysis can provide the ability to accurately simulate any number of cooling designs to optimize part quality and reduce cycle times, how cycle time impacts profitability, how the mold design impacts cooling, how proper processing can reduce cycle times and identify potential warpage issues.

He also shares tips for the supply chain. For example, molders and OEMs must insist on analysis, know their GPM for each line and do the math (what does X seconds of cycle savings mean?); part designers need to avoid difficult-to-cool areas, where possible and have an analysis team help with rib placement; moldmakers should follow cooling suggestions from the analysis and be creative and test using analysis; and, material suppliers should provide robust material testing.

To hear more from Tim as well as the answers to many attendee questions on the topic--such as, How do you calculate the average velocity of coolant to calculate the GPM? Do you get the cooling time out of Moldflow or do you set a time and see if it works? How do you determine the appropriate cycle time for a specific material type?-- click here.

RELATED CONTENT

-

Designing Flow Leaders and Restrictors

Use simulation to control flow in your injection molds.

-

Detecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.