Using CAD/CAM for Product Development

To show the value of CAD/CAM software in research and development projects, I wanted to share this story that was sent to me about an Italian plastic injection mold builder that combines craftsmanship with current technologies to offer fully integrated project management.

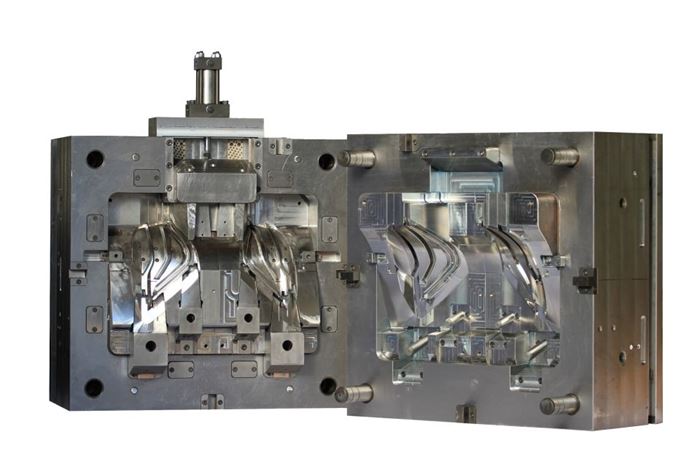

Although Omni-Stamp, an Italian plastic injection mold builder, is similar to many American family-owned mold shops, what makes it unique is its focus on research and development projects by combining craftsmanship with current technologies to offer fully integrated project management. An essential part of this process is CAD/CAM software.

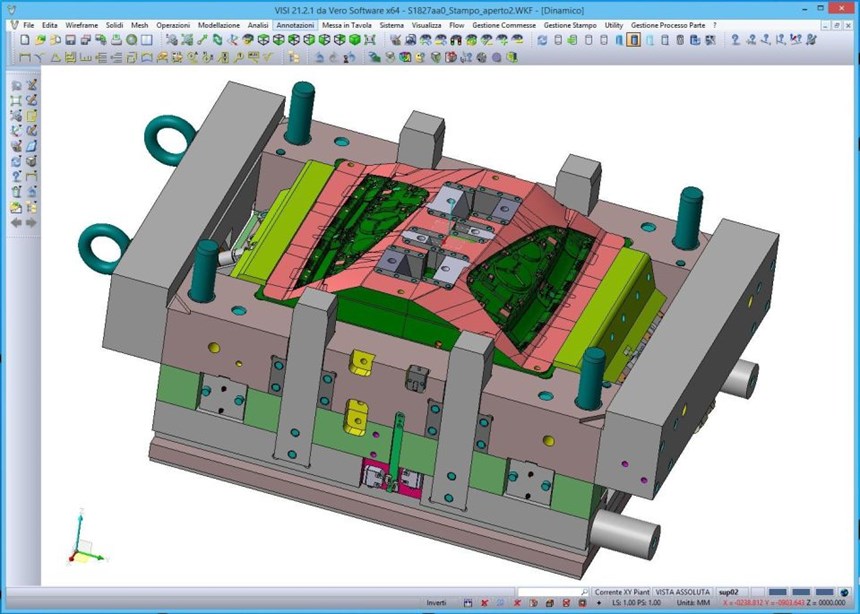

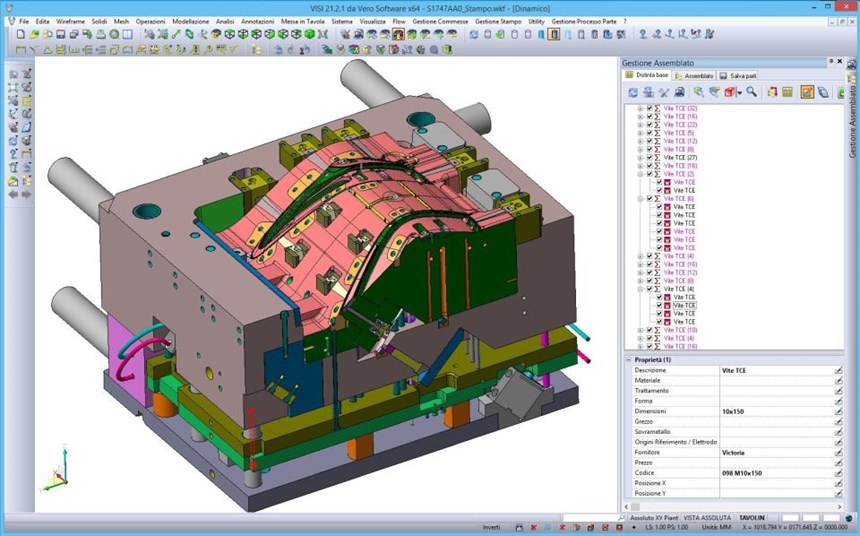

According to the company, VISI from Vero plays a critical role with customers at every stage, including research. For example, developing molds with channels shaped to guarantee greater cost effectiveness and energy efficiency with dynamic conditioning, and optimizing the models and parameters used to simulate the process through the use of pressure and temperature sensors inside the mold.

Once product design is complete, VISI helps find the most appropriate production solution, as per quality requirements, batch size and costs. The company has six VISI stations with VISI Modeling, VISI Flow, VISI Machining and VISI Mold modules, as well as viewers in the workshop.

To take research one step further, Omni-Stamp works with regional universities and research centers to study the transformation of polymers. One project involved thermally-conducting polymer nanocomposites for making heat exchangers. They tested the technologies best suited for converting thermally-conducting nanocomposites. According to the company, these materials are gaining interest in applications where thermal conductivity, resistance to high temperatures and good mechanical resistance at operating temperature are required at the same time. The materials tested showed critical issues and differences in transformation as compared to traditional polymers. Omni-Stamp simulated and optimized the process using VISI Flow, a plastic flow prediction tool, for pre and post production analysis and concurrent engineering of the injection molded components.

Another research project where VISI played a vital role involved the effects of microcellular molding, in terms of process, deformation and aesthetics, and combining it with dynamic mold conditioning. By optimizing process parameters and mold and part design, VISI helped reduce clamping force and deformation with microcellular molding alone.

Although Omni-Stamp plans to continue its involvement with R&D projects and working alongside customers providing the necessary support for pre-production molding, checking product dimensions, and mold maintenance and modifications, they are looking to expand services by creating non-conventional molds with advanced molding technologies and by creating equipment used by customers during the production stage that permits beneficial synergies if well interfaced with the mold.

Related Content

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

New Innovations in Mold Design, Milling Cutters, 3D Scanning

MoldMaking Technology compiles a number of digital-only products from the past month, including mold design software, laser metrology 3D scanners, milling cutters and more.

-

Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

.jpg;maxWidth=970;quality=90)