Third Graders Becoming Molding Experts?

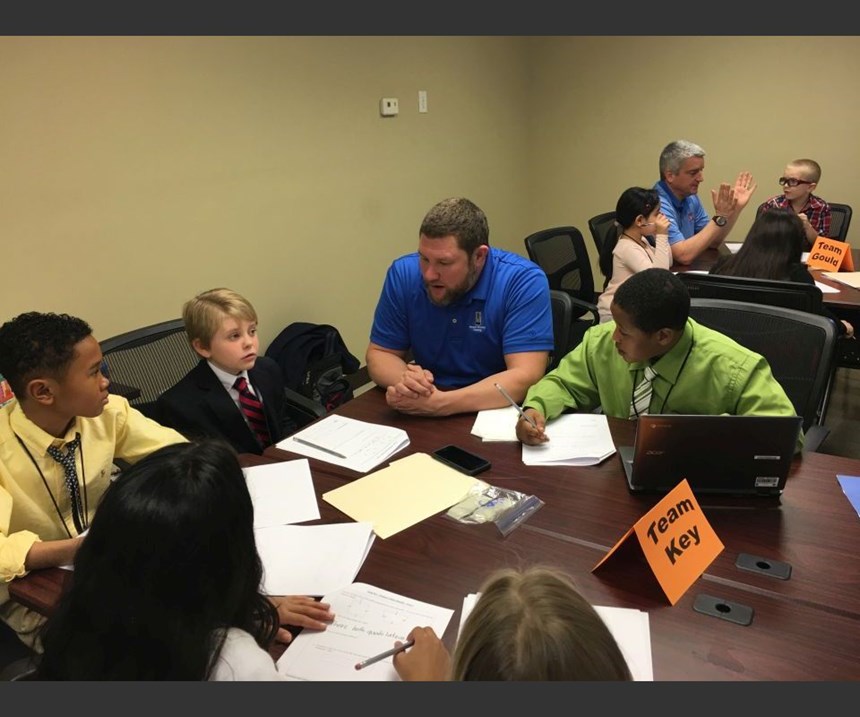

Third grade students from Chatham Charter School got energized and inspired during a day of learning and real world problem solving in injection molding at RJG's North Carolina facility.

Okay, not really—or maybe I should say not yet, because some of these kids may just pursue careers in our industry after the fun and exciting STEM field trip they had at RJG Inc.

The third graders are students of Mary Key, who teaches at the Chatham Charter School in Siler City, North Carolina. Mary is married to Marty Key, an RJG trainer and consultant. I’m sure you see where I’m going with this. When I heard about this field trip I contacted Mary and Marty to get more details and find out what the “after-effect” was from the experience.

“The idea of holding the STEM field trip developed as I worked through several math classes in pursuit of my Master’s degree,” Mary explained. “During these classes, the concepts taught seemed applicable in the classroom but foreign in my association with the real-world examples I try to present throughout the lessons I conduct in my own class. In order to increase student investment and comprehensions in math, I sought to find a way to provide them with real-world applications that appear to be so remote to elementary children. From this came a conversation that Marty had with Mike Groleau and RJG where he inquired about hosting a STEM field trip at their Gibsonville location and the rest, we shall say, was history.”

Indeed, the field trip was held, with Mary’s class spending an entire day at the RJG facility, practicing math in everyday situations and learning how it is used in a variety of science, technology, engineering, and math (STEM) careers. When I asked how the activities were structured for the students, Mary replied, “The basis of the experience was unique to say the least. I knew in order to provide my students with a forum that would ignite their interest in math, more than I had ever done before, I was going to have to pull out all the stops. Visiting the facility was not what I was looking for. I was looking for an experience that allowed students to become part of the process of math and all that it entails in the world of engineering. For this, I requested the assistance of a few local individuals who provided me with a scenario within their businesses that required several of the parts that could be produced at the RJG Gibsonville location. The goal of the event was to allow students to gain significant insight into the fact that math in the real world is not just about paying for groceries and balancing a bank account. It was aimed at providing them with a hands-on/eyes-on experience that showed them firsthand what the world has to offer as it relates to mathematics.”

Clever, needless to say. I was impressed, and I asked what were some of the mathematical exercises the students performed that day. She said, “For the assignments each student group completed, they were required to calculate word problems using formulas taught in class. This is a new push in the educational environment I have been working in as I subscribe to what is called CGI or Cognitively Guided Instruction. This requires me, as the teacher, to provide students with formulas, no matter how simplistic, that guide them through creating an equation, and them working to solve the equation based on math ‘rules.’ For these word problems, each team came up with numbers that were ‘used’ by Marty to plug into the machines in hopes of starting them.” She added that, in order to gain the greatest investment from the students, each team was assigned one machine and was able to stand front row in order to see their machines in action.

According to information provided from Chatham Charter School, the field trip has led to a significant increase in STEM interest throughout the school and, in fact, so many students have expressed interest in attending a class in the future that two more STEM field trips have been scheduled. In addition, four female students have said that they decided to pursue careers in engineering. That caught my eye, of course, so I asked for any updates on that. Mary said, “Absolutely! I will showcase one student in particular. She has a severe peanut allergy and during the annual entrepreneur fair that was held after our field trip, she developed a company that served as a ‘research compound’ involving a site where employees could conduct research to find a cure for the peanut allergy, eat meals at their on-site cafeteria and also manufacture plastic-injection-molded Y-body pieces (Marty provided these to me) that are used in the medical field for IVs so the vaccine could be given to patients at an “all in one” peanut allergy assistance facility. That’s a pretty awesome impact one day and some conversation can make.”

I agree. Mary summed up the experience by saying, “If there was one thing I could impress upon school systems everywhere, it would be to invest in field trips like this one for all students regardless of age. The results are priceless and unmatched in a regular classroom environment, no matter the manipulatives.”

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreExploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

Read MoreICYMI, MMT Chats: 30 Under 30 Honoree, Plastics Engineering TA Teaches Value of Learning and Producing Not Perfection

MoldMaking Technology Editorial Director Christina Fuges brings on UMass Lowell Plastics Engineering Teaching Assistant Michael Shone as a guest for this MMT Chat to discuss moldmaking through the lens of academia. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;width=700;quality=80)

.jpg;maxWidth=300;quality=90)