The Designer's Edge: Hydraulics and Switches

Randy takes a look at mechanical and proximity switches, which are two common switch styles used with hydraulics for set and pull position.

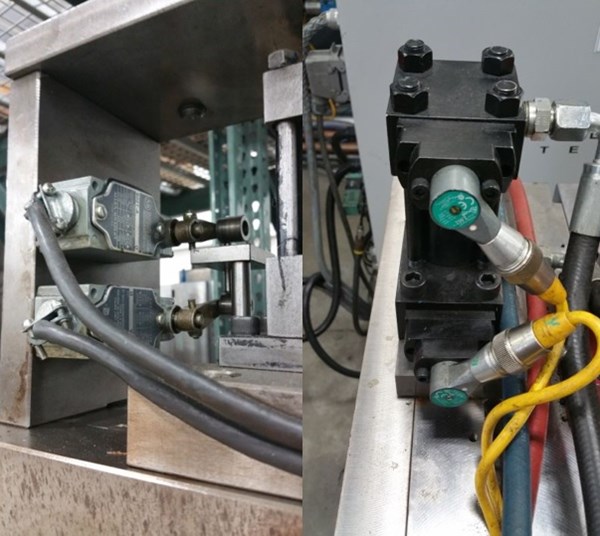

Proximity switch and mechanical switch.

When using mounting plates to attach the hydraulic cylinders to the mold you need to make sure the plate and bolts are robust enough to prevent flexing and broken bolts from the stresses. Many failures occur due to inadequate mounting plate thickness and bolt size. Also, whenever the cylinder rod is attached to the component with threads you need to make sure the hole is tapped perfectly straight/square. You should also consider doweling the plates in position so that everything stays in the center of the cylinder. To reduce the chances of threads working loose over time, use a lock tight or set screw.

Mechanical and proximity switches are two common switch styles used with hydraulics for set and pull position. Although a mechanical switch would be my first choice, proximity switches are used in most cases due to their compact size and being part of the cylinder. These read magnetically and sense the position of the piston—either directly on the piston itself with the sensor bolted in a hole in the wall of the cylinder or through the cylinder wall when made of aluminum or stainless steel. When using sensors that are bolted in a fixed position, timing of the component for the set and pull position is critical. This helps keep the piston in the correct position, so sensors can read it in the set and pull position.

Sensors that read through the wall of the cylinder can be adjusted to any position, so timing of the component is not as critical. But when using aluminum cylinders, you need to make sure they can withstand the cavity and hydraulic pressures. When using proximity sensors you need to take temperature into consideration, as most will not read properly over 150 degrees. Also, switches that read magnetically can create issues. For example, we had metal chips get inside the lines and a tool crashed because it was reading the false position and the machine cycled.

Later this month look for the subject to change to lifters.

_300x250 1.png;maxWidth=300;quality=90)