Tech Tour Brings AMBA, SPE Members Together to Inform

The American Mold Builders Association's Chicago Chapter and the Society of Plastics Engineers' Mold Technologies Division partnered recently to provide a forum for learning and networking.

Share

Tech Tour Brings AMBA, SPE Members Together to Inform

A wonderful event happened recently that I want to blog about. It was wonderful because it brought together two groups of people that have not often congregated before even though they both represent the moldmaking industry. The groups are the American Mold Builders Association’s Chicago Chapter and the Mold Technologies Division of the Society of Plastics Engineers. Together, they hosted a Tech Tour event at A-1 Tool Corp. in Melrose Park, Illinois, that was quite a success.

More than 50 attendees toured the A-1 facility, broken up into seven smaller groups with “tour guides” leading them from station to station. Every 15 minutes, groups were instructed to move onto the next station to keep things rolling along, as time is valuable. The event culminated in a Q&A session with host Geoff Luther, president of A-1, and representatives from the supplier companies that sponsored the tour and staffed stations to answer questions about the equipment and technologies on display. Supplier companies who participated included Sodick, Schmolz and Bickenbach, Creative Technology Corp., Progressive Components, OSG, Synventive Molding Solutions and Swoosh Technologies.

MMT was in attendance—both myself and editorial director Christina Fuges, who was in town, and we both agreed there should be more of these kinds of collaborations done across North America. When I asked a few of the attendees from mold shops about it, they, too, said the event was well worth their time and that they would attend more in the future. As crazy busy as I know mold shop owners and managers to be, that’s quite an endorsement.

I also queried my respondents to share more specific observations with me about the tour. Here’s what they told me:

MMT: Overall, what did you think of the event?

Renee Nehls, Tooling Engineer at SussexIM, Sussex, WI: It was great! I liked the pre-organized groups. The tool shop was very prepared for the tour. It was clean, production process was well organized, knowledgeable workforce at the respective machines, knowledgeable guides.

Chuck Klingler, VP Business Development at Janler Corp. in Chicago: Good vender positioning, and very knowledgeable representatives. Very good, diverse offering.

MMT: Did you find one of the stations particularly interesting?

Nehls: Most stations had large screens identifying each workpiece and its status, which was interesting. I was also impressed by the very large Deckel Maho DMC 125 FD duoBLOCK five-axis CNC milling-turning center. What struck me besides the size of the machine was the ability to drill water lines at an angle to match the part-wall angle. For example, large garbage cans. This capability will definitely influence cooling abilities.

Klingler: Synventive’s multi valve gate and individual actuation hot runner system was very impressive.

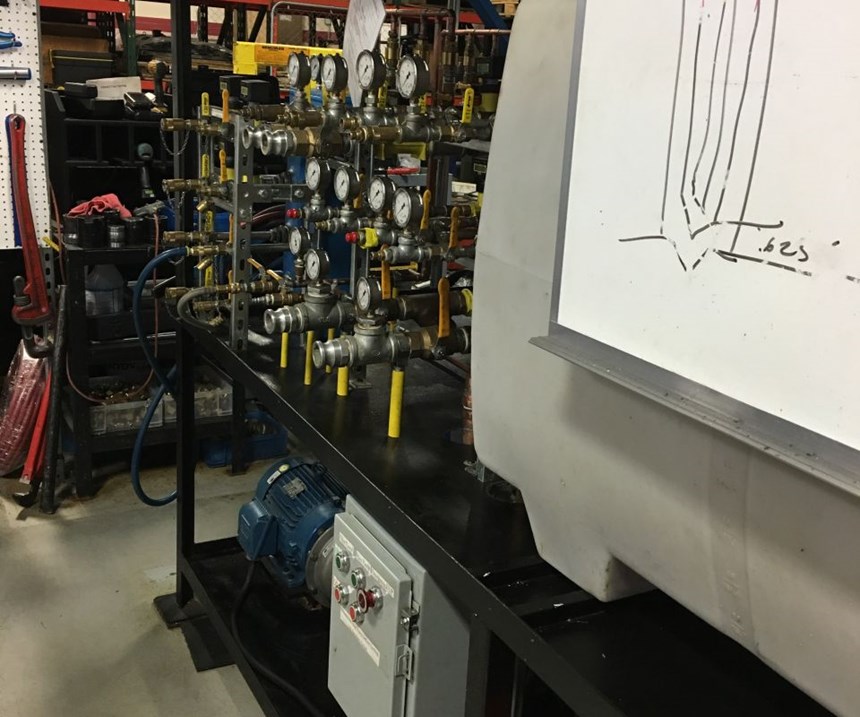

Jeff Noud, automation manager at Industrial Molds Inc. in Rockford, Illinois: The water station. This is a very unique perspective and operation in regards to workflow and training. I really like the fact that every part of the tool assembly is broken down into stations. This not only helps in the quality of the tool, but also help young apprentices learn and train.

MMT: Did you find some notable similarities or differences between A-1 and your company?

Noud: Yes, similarities. The systematic approach to mold building and relying on a team instead of a couple individuals to do it all.

Klingler: Janler is performing the same ERP and detailed process functions, and following the same shop planning methods, but A-1 handles much larger steel, producing much larger molds. It’s very Impressive.

Nehls: The engineering department. From what I gathered they were well-staffed. The industry has “awakened” immensely in this area, and by that, I mean back in the day, mold designers where thought of as unimportant/bottom-of-the-food-chain (and paid that way). Toolmakers were the end all, be all. However, with the huge swing from 2D to 3D manufacturing, that tide has turned. Mold designers need to have a “toolmaker” sense about them. Within many companies, the manufacturing process uses 3D models and 3D models only on everything from simple mold-base plates to complex cavities and cores. The “toolmaker discretion” is no longer part of the equation or is minimal compared to how it used to be. For example, they used to provide critical input—add chamfer here, cannot add chamfer here, running clearances, etc. All of that is now done by the mold designer. Yes, the toolmaker still has to have a strong skillset on such matters, but much of the “toolmaker knowhow” has already been designed in. I have worked at companies that have done it both ways, with all running clearances, chamfers and such done within the mold design. Then some but not all of the aforementioned items are managed by the toolmaker. A-1 Tool, without question, works off 3D models—followed by “some assembly required.”

I would have liked to collect feedback from every moldmaker attendee at this event. There are so many perspectives from which to view a colleague’s company. Yes, as a competitor is one, but that’s the cool thing about this industry. Most of those I’ve come to know through the years may consider others competitors, but they are also willing to open their doors, or simply lend a hand, to fellow moldmakers if asked. It’s the way of this industry and this event proves it out, as do the shop tours AMBA’s national office hosts each year. To see more images from the Tech Tour, visit Creative Technology's Facebook page.

Related Content

Free Injection Molding Training, Hands-On Demonstrations

Visit RJG’s booth at the K Show to watch training segments from its trainers worldwide, receive hands-on demos of the CoPilot system and view the power of The Hub networking system.

Read MoreICYMI: MMT Chats: True Leadership Leads to Mentoring, Part 1

This trio from TK Mold and Engineering in Romeo, Michigan, joins me to discuss the role of leadership and culture in mentorship. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreVIDEO: Explaining MoldMaking Versus Mold Manufacturing

To understand how training has been impacted we first need to understand the differences between a few key concepts. What is moldmaking vs. mold manufacturing? Who is a mold designer vs. a mold engineer?

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)