Amerimold Presents MMT's Top 10 Reasons to Be a Moldmaker

Get ready! Here are the top 10 reasons you told us why you love being a moldmaker.

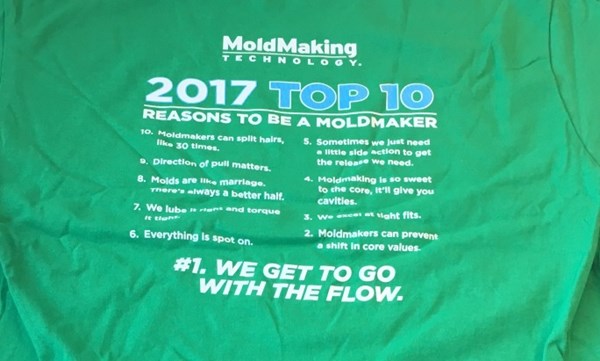

Now in it's 16th year, the annual "Top 10 Reasons to be a Moldmaker" reflects the community, camaraderie and sense of humor that has come to define the mold manufacturing industry. If your submission is selected, it is printed on this t-shirt and distributed at Amerimold from the MoldMaking Technology booth.

Authors of submissions selected for the Top 10 receive an Amerimold ALL ACCESS PASS to the exhibit hall, Tech Talks, Networking Reception and their name, title, and company name in the Amerimold 2017 Event Directory! The author of the #1 Reason to Be a MoldMaker also gets $250 Visa gift card.

2017 Top 10 Reasons Are:

10 Moldmakers can split hairs, like 30 times.

9 Direction of pull matters.

8 Molds are like marriage. There’s always a better half.

7 We lube it right and torque it tight.

6 Everything is spot on.

5 Sometimes we just need a little side action to get the release we need.

4 Moldmaking is so sweet to the core, it'll give you cavities.

3 We excel at tight fits.

2 Moldmakers can prevent a shift in core values.

1 We get to go with the flow.

Winning submissions by:

Read Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)