MMT Blog

MoldMaking Technology's Hottest Tips of 2023

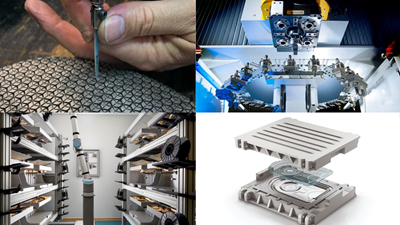

The staff at MoldMaking Technology prides ourselves on bringing you the most helpful, relevant tips in the industry. Here are the top five most-viewed tips of 2023 based on Google Analytics.

Read MoreMachine Tool Considerations for Today's Mold Builder

Machine rigidity, spindle speed, power and control options that run complex programs smoothly are vital to meet the industry’s surface finish and speed requirements.

Read MoreMold Design Tricks, Additive Manufacturing Treats & More: MMT's Top-Viewed Articles in October

October held some tricks but mostly treats for MoldMaking Technology’s audience.

Read MoreNovember Product Highlights

In this most recent roundup, MMT continues to present the breadth of new or proven technologies that target the moldmaking industry, from cutting tools to software to molding-related products, that have been shared this month.

Read MoreMachine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Using data from a machine monitoring platform, Westminster Tool added almost 75 hours of capacity per week by shortening warmups and starting CNC and EDM machines sooner.

Read More5 Steps to Get Started With Digitalization

Knowledge, a strong partner, an internal champion and an active regular participation in highly visible data will help smaller mold shops with digitalization.

Read MoreEditorial Advisory Board 2023-2026: Camille Sackett, Vice President of Sales and Marketing for Accede Mold & Tool

The 2023-2026 version of MoldMaking Technology's EAB features a new crew of industry professionals. Meet Camille Sackett

Read MoreSelect End Mills With Mold Material, Features and Machining Process in Mind

Here are some factors to consider when choosing cutting tools for pre-roughing, hard milling, steep walls and tough materials.

Read MoreMMT Chat: Key Principles of an Automated System

PFAFF Molds develops its automated systems to address key customer pain points – such as high worker turnover, rising costs, volume fluctuation and sustainability.

Watch3D Scanning Quickly Solves Tool Repair Problems

3D scanning supports the repair of molds with no history, drawings or design files.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHonoring Excellence in Mold Manufacturing

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards competition returns to recognize outstanding performance and innovation in the moldmaking industry.

Read More

.jpg;maxWidth=300;quality=90)