What Machine Consolidation Can Mean for You

How to expand your production and profits in milling and high-speed cutting.

One of the main driving forces behind technology advancements in manufacturing today is consolidation. Everyone is trying to do more with less, and faster cycle time is more important than ever across many industries. With new products coming to market every day—and increasing competition and demands—more efficient production methods are crucial.

Milling is a particularly challenging process to optimize for fast-production applications because of the complex geometries and time-intensive programming that is often necessary. In addition, few milling machines can offer increased volume capabilities and decreased downtime. For this reason, addressing this issue has been an important emphasis for technology developments.

The Multitasking Option

The machine tool industry needs high-speed, high-volume machines that can provide accurate, capable milling and high-speed cutting. Cost is a consideration, however, as many shops historically have avoided offering these capabilities because it was just too expensive. How can you combine the milling power of a VMC and the ultra-high speed of a drill-tap center? Done right, many of the downfalls of drill-tap machines on the market can be addressed, including subpar rigidity, slow tool-change times and less accurate finishing.

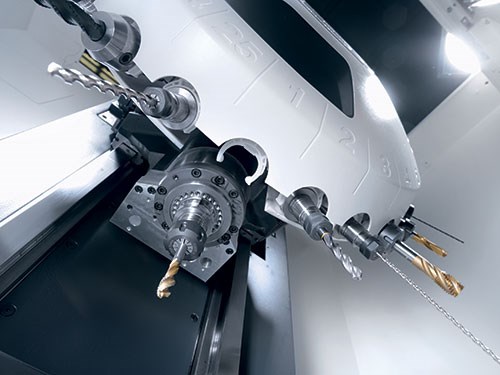

One way to answer these challenges is with a multitasking machine. These types of machines offer more advanced machining capabilities and enable manufacturers to combine several processes and cutting techniques on a single unit, often with standard, off-the-shelf tooling. The time and cost savings are significant.

Multitasking is an area of interest for those in mold manufacturing because it can greatly reduce or eliminate benchwork time. The multitasking machine’s real value is in the precise finishing applications it provides. The appropriate machine can be an ideal solution for those who are more concerned with finishing applications than with roughing and with having those applications completed quickly.

Machine Considerations

Look for a machine that combines speed, rigidity and high dynamics in one concept. Consider one with a C-frame design, a traveling X axis with a 700-mm stroke, a 5.4-foot-wide footprint and a table that can load as much as 880 pounds without any speed restriction. Most other cross-table concepts typically cannot handle large workpieces at high speed and still maintain accuracy. The right design concept will lend itself to high-speed moldmaking because it offers the rigidity and size accommodation needed for large injection molds.

Because it plays an essential role in the machine’s productivity and accuracy, a higher-end control also is necessary. Such a control that enables the operator to switch the dynamics of the machine easily and quickly through roughing, semi-finishing and finishing is particularly useful for moldmaking. The control should also be extremely user-friendly and make it easy to optimize each tool for its specific operations.

Optimal rigidity is determined by whether the machine can produce more cubic centimeters/inches of cut metal per minute than another machine. Increased machine rigidity also means more accuracy and less vibration, which results in better surface finish and longer tool life.

A particularly important factor in reducing benchwork time is the spindle. While most will associate a high-speed spindle with aluminum cutting (or bottle molds), a 24,000-rpm spindle is essential in ferrous applications of mold manufacturing as well. Complex mold cavities require small-diameter tools, and achieving 800 square feet per minute with a tool 0.125 inch in diameter requires 24,000 rpm.

Another important feature for a multitasking machine’s spindle is whether it offers almost the same torque at low speed that the standard spindle offers. This results in little compromise in roughing while reducing cycle time in finishing. Add to that a high-speed toolchanger, and you should be able to achieve chip-to-chip times of less than 1.5 seconds.

A spindle that drives the turret of the toolchanger is not unique, but the way in which it drives the turret can be—for example, inside the spindle stock instead of running up a gear reel on the spindle nose, which brings a lot of imbalance and noise. This design eliminates the rotating gears, greatly increasing the life of the spindle.

Also consider a 33-hp spindle designed to push the limits of a typical drill and that has built-in water-cooling capabilities, because these unique features allow for continuous machining at maximum speeds. Both a water-cooled spindle and water-cooled motor enable manufacturers to use the machine at maximum speed 100 percent of the time.

Because high-performance multitasking machines are built for high-volume production or automated machining, chip disposal is another factor to consider. When you purchase a machine to make a lot of chips, you don’t want to stop the machine because of those chips. The secret to better chip flow and superior accuracy is optimized table construction. A triangle-shaped table and thermal stability both help with this chip flow.

Summary

In order to optimize production and profits in milling and high-speed cutting operations, mold manufacturers should consider a multitasking, high-speed mill. New technologies have eliminated barriers and significantly improved the process, and operations stand to get even more accurate, faster and less expensive in the future.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Manpower, Machine Time Maximized with Highly Accurate VMC

“Using highly accurate machines allows more efficient utilization of manpower and machine time—saving time and money for the customer and making BPM more profitable.”

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More_970x90 4.png;maxWidth=970;quality=90)

_300x250 4.png;maxWidth=300;quality=90)