Total Cost of Ownership and Productivity Analysis for EDM

Using the graphite TCO model shows business owners how to save time and money in their EDM operation.

In the competitive moldmaking industry, throughput is the key to keeping production costs competitive. Shops want to increase productivity while maintaining profitable margins on their sinker EDM-related operations. Part of management's strategy is often the inclusion of new equipment and technology. Investing in technology is as important to global competitiveness as optimizing asset ownership.

The TCO Analysis

The Total Cost of Ownership (TCO) model and analysis is commonly used to make decisions when purchasing new equipment. Part of this evaluation process should include an audit: an evaluation of current equipment and manufacturing operations to determine the capacity or capability for meeting present and future operational requirements.

An audit is used to do the following:

- Compare actual performance versus benchmark performance of the equipment

- Examine areas to improve productivity

- Look at lost revenue due to inability to quote desired new business

- Evaluate slow production and inability to meet deadlines

- Check scrap rates due to out of tolerance cavities and flaws in the cavity

- Track servicing and maintenance of out of warranty equipment

- Analyze economics of upgrading, refurbishing, or disposing of existing equipment as opposed to replacement

The main cost elements are purchase, energy, maintenance and repair. Secondary costs that have a bearing on the overall value are productivity, risk and disposal. A value assessment reflects all costs associated with a capital purchase, including owning and operating, over a given period of time. This information is a useful tool in optimizing asset ownership and determining the best value between several alternatives.

A good TCO analysis should fit the business plan and identify the best solution to match the business goals; for example, adding capabilities in order to service new customers or expand into different markets. Using new technology can often eliminate some of the process and take a fresh approach to jobs. Additional capacity and improved machine performance are often the drivers in the decision to look at equipment changes.

TCO and EDM Equipment

When cost of ownership principles are applied to major elements associated with the operation of the sinker EDM equipment, such as graphite materials, costs associated with the value proposition and productivity start to impact profitability of owning and operating the equipment.

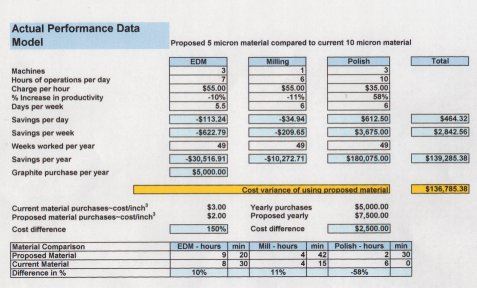

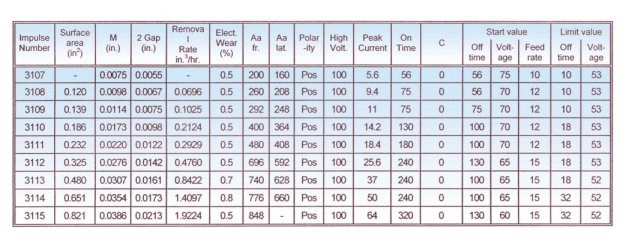

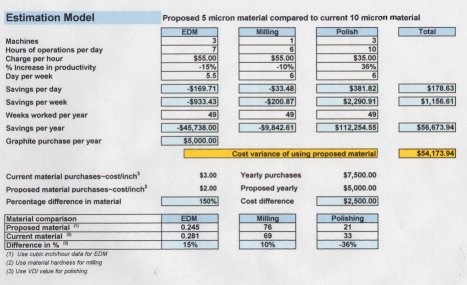

Using benchmark data from equipment and graphite vendors (see Chart 1), an audit of the EDM process helps identify areas of potential savings by comparing actual costs against accepted benchmarks. Using the TCO model to audit the process may show that additional capacity can be gained from the existing equipment and the EDM machining hours can be reduced, thus increasing productivity. Once opportunities for improvements are identified, the TCO process is then used to identify the alternative with the lowest total cost, or best value, based on the needs of the company as identified in their business plan.

Electrode Material

The audit also shows that one of the most critical elements of operating EDM equipment is the electrode material because the material's performance affects the productivity of each job and the capacity of the shop. Each equipment manufacturer publishes charts that show typical metal removal rates and percent electrode wear for specific machine settings, work metal and electrode materials when EDMing under optimum conditions. One can use the same parameters and measure the actual metal removal rate and percentage of electrode wear to compare how close the machine is performing to the benchmark. If the operation cannot achieve the benchmark numbers then the shop may have slower production cycles than other competitive shops. Using this benchmark data combined with actual machine performance will indicate if the current capacity of the machine has been reached. If the current machine is not reaching the benchmarked production stated by the manufacturer, there are often productivity gains to be made by changing to a high-performance electrode material. These benchmark settings could be related to speed, wear or finish, depending on the requirements of the work performed in the shop.

Once the reason for the new equipment is identified, the audit may show that there is extra capacity to be gained and productivity issues that need to be explored without adding new equipment. This is particularly true if the graphite electrode material is the root cause of productivity issues. Productivity can be reduced in a number of ways if the best graphite material for the job is not used: unstable cutting extends the time the job will remain in the tank, material is unable to produce the desired surface finish efficiently and scrapping parts due to out-of-spec tolerances or surface pitting. Purchasing new equipment may improve these problems, but using the best graphite for the job is the best solution.

The characteristics of the electrode material also affects other shop operations or cost centers, such as electrode fabrication and mold polishing cells. Additional electrodes or redressing of electrodes due to high electrode wear also shortens tool life and increases job costs. The material's inability to produce the desired surface finish can increase the amount of polishing necessary to finish a cavity, which also increases job cost.

Using high-performance electrode materials increases profitability by decreasing electrode fabrication time, EDM machining time and polishing time. Shops that only look at the cost per cubic inch of graphite, rather than the total production costs associated with the job, may actually be losing money because they are not purchasing the best material for the job. Even if there are no problems with capacity, an inefficient machine is still consuming electricity, reducing the dielectric fluid and filter life in addition to the added labor costs.

TCO and Graphite Material

Just like equipment manufacturers, graphite manufacturers can supply models and benchmarking data to aid in the TCO analysis. Electrode wear, metal removable rates and surface finish are influenced by the grade of graphite selected. The grade of graphite should be selected on the material's suitability to achieve a specific surface finish, reproduce critical detail or optimize metal removal rates. Selecting graphite without considering the properties of the individual grade can result in poor EDM performance. Using the best graphite for the job can reduce the number of electrodes due to improved wear and reduced polishing because the desired surface finish is reached quickly.

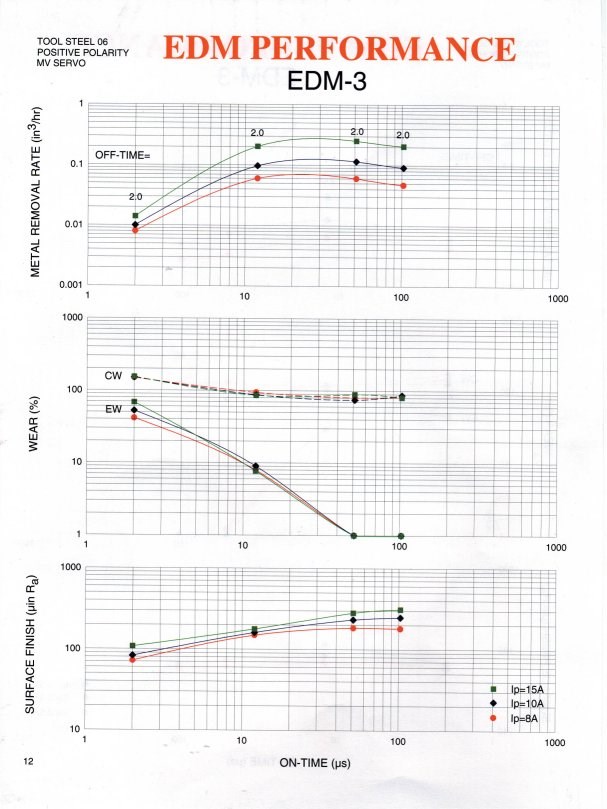

Graphite manufacturers publish charts or graphs that show metal removal rates, electrode wear and surface finish for specific grades under a variety of operating parameters (see Graph 1). This information can be used as a benchmark when comparing various grades of graphite.

Another tool to use when comparing graphite is photomicrographs of the microstructure of the graphite. Because the sinker EDM process is designed to produce a mirror image of the electrode shape in the work metal, the quality of the graphite is an important part of the process. Materials that have uniform structure and small grain typically are capable of reproducing a mirror image of the electrode detail in the metal cavity with fewer electrodes. Since the surface finish also is a mirror image of the microstructure of the graphite, large grain size materials with non-uniform structures typically produce finishes that require polishing.

The TCO model looks at the impact that the graphite material has on the EDM-related operations in the shop from electrode fabrication through the mold polishing operation. The goal is to identify productivity increases to reduce production costs. If the graphite grade is the limiting factor in the operation, this factor will continue to affect the operation when new equipment is purchased.

Often a different graphite grade will show enough electrode wear improvement that fewer electrodes need to be fabricated or redressed thus reducing consumption of graphite, milling time and tooling. Efficient EDMing with a graphite grade capable of achieving a desired surface finish can minimize polishing time. Adaptive controls respond to conditions in the gap, such as excessive debris from electrode wear (graphite grains), reducing the efficiency of the cut. It is important to use actual conditions rather than an estimate based on short test cuts. Although test cuts are fine for benchmarking or estimating performance, they don't reveal the true cost of the graphite in EDM machining time and the price of the material when wear and number of electrodes are considered. Comparing two grades of graphite in the actual shop environment shows the impact that graphite performance has on the job.

TCO Graphite Model Example

When the model is used as an estimate, actual shop data is entered for number of machines, hours of operation per day, hourly rate, days worked per year and the cost of current graphite and recommended high performance graphite. The model uses standard (conservative) metal removal rates and milling times from a database of test results from available graphite grades.

The greatest benefit of the model is the ability to capture side by side comparisons and project overall efficiencies using high-performance graphite. Each shop has a different set of conditions; an applications specialist should work with the shop to review the type of job and recommend a grade or multiple grades for the application.

In an actual case, after working with an equipment salesperson on TCO analysis, the shop owner requested assistance performing the EDM audit from his/her graphite manufacturer. Using their cost performance model, they estimated increased productivity using high-performance graphite that was more suited to the specific application. The results convinced the owner to change materials rather than purchase new equipment to solve this problem (see Figures 1 and 2).

The main reason for considering the purchase of a new machine was the inability to get the desired surface finish from their manual EDM machine, causing the hand polishing operation to be unprofitable. They believed that a CNC machine with orbiting capabilities would solve their finish problems. Although orbiting would have shown a small performance benefit, their current electrode material would never have allowed the new equipment to reach the desired goal. For the type of mold work they were doing, they only had to cut their polishing time by five minutes to cover the increased cost of the high performance graphite material best suited to the application. They actually moved up two grades to a five-micron material that cut their polishing time in half.

The model used in this audit showed that by increasing the quality of the electrode material, they could produce the required surface finish on their existing equipment, eliminating the need for capital purchase while still achieving the goal of the shop and managing their TCO.

The TCO is the best solution for making decisions when purchasing new equipment because it brings together all the factors and identifies opportunities to optimize productivity.

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

Automation Is the Bridge Between EDM and Precision Mold Manufacture

The automation route has three key milestones: (1) tooling, (2) palletization and (3) robots, all of which should neatly slot into each other and help govern the speed of change.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More_970x90 1.png;maxWidth=970;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)