ToolTalk

Part development included throughout tooling and production.

#Leadership

In the high stakes game of product development, OEM’s know that market share can swing quickly. As a result, product release timelines are continually compressed, making it very important to release a product to market as soon as possible to avoid falling behind a competitor with a similar product.

However, a product’s release date and profitability can be threatened by problems and inconsistencies stemming from tooling and molding issues. In order to remove the risk that these problems might occur, a different approach has been developed that involves better connectivity throughout the design, tooling, and molding aspects.

“The Perfect Part”

Many factors will influence a plastic part’s design as a part of an overall assembled product. Initially, the marketing and industrial design will determine the overall visual appearance and function of the end product. Further on, electrical and mechanical design will directly impact each individual part design, with input also coming from material suppliers, as well as processing and tooling personnel. But in the end all eyes will be focused on the production cost.

It will justify the feasibility of the release of the end product and generate the expectations as to the profits it will contribute.

It therefore becomes necessary to have a manufacturing system in place that comprises the following comprehensive steps for creating “the perfect product” and helps keep production costs in check:

• Combine Design for Manufacture (DFM) with “kit style tooling”;

• Add in Process Optimization; and

• Prevent product development and production release from occurring in various “silos”.

Optimized injection molding consists of three main areas:

- Design For Manufacturing (DFM) – To get the best possible part design for production.

- Pre-engineered Tooling – To have reliable and cost competitive production tools available

- Injection Molding Processing – To develop the best possible injection molding process for consistent quality during production

Let’s overview each area to gain a better understanding of the role it plays and the effect it has on the overall manufacturing process and outcome.

DFM

Design for Manufacturing analyzes the molded component design with regard to filling behavior. It also aids with material selections and will address the overall manufacturability of the component configuration. Using a structured approach with a structured documentation trail, the design is developed for the customer and all involved in the process, while all molded component related technical data is stored in one, revision-controlled place. Using this systematic approach makes it possible to make precise predictions on tooling, processing, cycle times and the production environment.

Featured Content

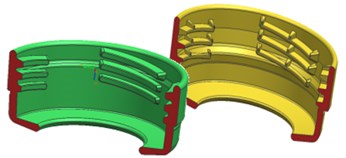

This baby collar cap shown in green was able to be optimized for efficient tooling and molding (yellow, redesigned version), resulting in 12% material savings and 42% lower cycle time.

The Flow analysis performed during DFM also showed that the part quality was improved significantly.

Pre-engineered Tooling

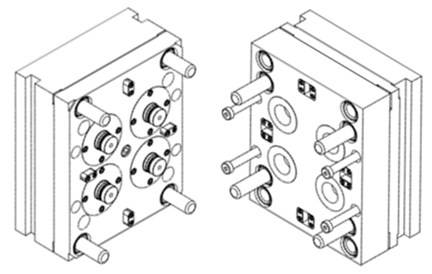

A customer-owned tool standard or requirement specification will shorten lead times and facilitate better cost control. To eliminate surprises and downtime, consistent mold inserts and components can be used for tool production, easing tool maintenance and tool repair. A certain level of reuse of mold components such as mold bases and hotrunners can be possible and, when combined with specific tool design rules, one can ensure that one gets the same tool and molded part quality from different suppliers.

In addition, the mechanical design and supporting DFM work is much more straightforward because everyone involved in the project understands and knows the capability of the tool standard and demolding features to be used.

Injection Molding Processing

A stable injection molding process results in a safe and cost efficient production outcome.

Many injection molding processes are set as a result of an individual’s expertise and knowledge of the machine, mold or material. Too often tooling or part design issues dictate how a mold will be run. The process becomes reactive rather than proactive.

The consistency of the injection molding process has a direct effect on quality, productivity and profitability. A structured and repeatable approach is needed to ensure that the best possible injection molding process can be achieved.

Continued involvement with DFM personnel during this manufacturing phase assures not only consistency for the program at hand, but also a continuous learning cycle for the entire team to hone the evolution of the most efficient practices together.

A Continuous DFM Mindset

DFM support can be seen as a link between not only part design, but tooling and molding as well. Using a structured DFM approach and predefined DFM templates makes it possible to provide the tooling and production department with critical, upfront information prior to the tool builds.

Product development often becomes a race that does not include the initial engineers throughout the process. But, rather than viewing it as a luxury, embedding the DFM mindset throughout a project ensures that the prizes that were envisioned will be achieved.

RELATED CONTENT

-

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

-

The Meaning of the Five "M's"

Man, material, machines, methods and metrics. What does this refer to? A suite of technologies, hardware, software and services focused on returning leaked profit to a company's bottom line.

-

Maximum RPM Machining: Necessities of High-Speed Moldmaking

Mold shops will thrive if they practice an ‘all-aspects’ process to HSM, which includes the machine, cutting tool, toolholder, proper balance and application support.