The Plastics ISO 9000 Model 2 - Moldmakers' Pioneering Spirit Will Guide Quality Standards Through This Millennium

Small tool shops and moldmakers need a solid foundation for excellence, since they are the starting point in the supply chain of producing a quality end product.

ISO 9001:2000 for the plastics industry (tooling-processes-materials) certification means that a company has in place a policy and procedure to ensure that quality is practiced in a uniform manner in every step of the company's administration, product and mold/die design, manufacturing, packaging and shipping processes. It implies that every person working in the company conforms to procedures - from answering the telephone to sales/customer service, purchasing, inventory control and engineering. It is assumed that if all of these procedures and company policies are in place, quality is a given, evidenced by a performance assessment/audit report card through monthly management reviews. Continual improvements and customer focus are the goals.

ISO 9001 ... "model for quality assurance in design, development, production, installation and servicing" ...is the most comprehensive quality system standard for toolmakers and plastics processors to follow serving all markets (medical, pharmaceutical, automotive, electrical/electronics, appliances and industrial).

New ideas and new perspectives are transforming quality as it makes the leap from the industrial age to the information age. Small tool shops and moldmakers need a solid foundation for excellence, since they are the starting point in the supply chain of producing a quality end product. The only difference between our perspectives, it appears, is the meaning of effectiveness and efficiency.

We use the long-standing ISO TC 176 definitions (ISO 8402 and ISO/DIS 9000:2000 definitions):

- Effectiveness is a measure of the extent to which planned activities are realized and planned results achieved.

- Efficiency is the relationship between the results achieved and resources used.

In other words, effectiveness relates to meeting requirements and efficiency deals with the cost of achieving the requirements. In this article, the point of placing effectiveness at the baseline is, first and foremost, that the requirements must be met. ISO 9000 auditors do not evaluate how much it costs to implement a quality management system. Their concern is with whether the requirements are met. The quality hierarchy model relates effectiveness to efficiency. To be successful, moldmakers and molders must meet requirements in an efficient way. Moldmakers and molders need to minimize waste, scrap, rework, operating labor, cycle time and all other costs to remain competitive. But reducing costs is only meaningful if the requirements are met first. Without meeting the requirements first a moldmaker and molder have a defective product, dissatisfied customers, reduced sales and lower profits.

What Makes an ISO Quality Shop?

Tooling engineering firms have a pretty simple philosophy: The customers are the future and reputation of their shops. Everything they do is designed to ensure customer satisfaction and perpetuate the growth of both businesses through quality initiatives. Clients have the opportunity to select and work with any number of custom mold manufacturing shops. All the more reason we emphasize to every shop the importance of individual effort in new ideas, quality control, meeting deadlines and utilization of the most advanced technology available. For years tool shops and moldmakers have dedicated themselves to creating molds for plastic injection, extrusion, transfer, die casting, multi-cavity, prototypes, insert molding, rubber and compression needs.

Equipped to Excel

The right type and quantity of equipment is important. Moldmakers are best equipped to help the client excel by the people on staff. Their commitment is that each person is highly motivated to ensure customer satisfaction. As a team, the mutual reward is a growing business that is guided by customers' personal expectations. These quality people ensure the client of precision and quality in all products with the latest technology in CNC wire and sinker EDM, fixtures and CNC JIG grinding. You also will find advanced milling and lathe capabilities at your service.

Beyond Expectations

Large capacity EDM machines and the ability to cut up to 30-degree taper angles are two extraordinary capabilities toolmakers offer. Also, they can cut up to 16 inches thick. The commitment is always to go beyond clients' expectations. Shops have invested heavily in CAD/CAE/CAM services to partner with customers in product development. True 3-D assures the client of realistic drawings and helps create prototype support to meet clients' short-run requirements. Another unique advantage to the client is a shop's 24-hour auto-dialing service that helps keep turnaround time to a minimum. They employ this system because it's simply not good enough to try and accomplish clients' deadlines. They want to meet every delivery goal or tell you upfront that they cannot.

Open-minded

Molding companies, injection houses, metal stampers, aerospace, tool and die manufacturers, and the automotive and the medical industries are some of the benefactors of tool shops' creativity and quality commitment. You will find these open-minded and accessible shops across the U. S. Their pledge is to listen and learn from each customer, as well as share their vast experiences and leadership in the custom molding field. They welcome partnerships with clients to develop new products and work with the client for all of their needs from print to design to building and sampling. To further enhance service to the client, they offer additional capabilities such as mold repair and maintenance.

User Friendly Documents

The ISO 9001 glossary (see sidebar) will help you understand and divide your documentation system into three major tiers as follows:

- The ISO 9001 quality manual

- The procedures manual

- The work instructions manual

The quality manual is based on the 20 elements in ISO 9001, with a statement that the company will have procedures in place to address the requirements. While the procedures describe how material and information flows are organized in the processes, the work instructions detail the steps in the sub-processes.

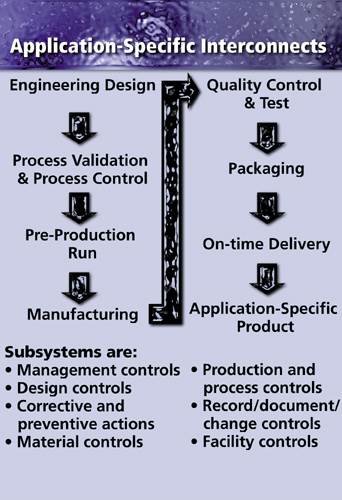

Use graphic flow charts when displaying a company's processes. Flow charts can make the process easier to visualize and improve the readability of the document significantly. A flowchart also can be used as a tool for process improvements - for example during brainstorming sessions.

The maintenance of the documentation system can sometimes be costly and time-consuming if the documents consist of too many pages. Keep documents short and simple. It is advisable to have more documents with fewer pages rather than fewer documents with too many pages.

Recognize and Reward Collective Achievement

Recognize the collective achievement of ISO certification with a formal letter addressing the team effort of the staff. Some companies view team activities as a continuous improvement effort. Alter all, moldmakers' pioneering spirit will guide quality standards through this millennium.

Related Content

From Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

ISO 9000 Model 1 - Quality Issues as a Part of Good Business

Solutions for managing the plastics supply chain improving OEMs' total cost of manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)