Tech Tool & Mold, Inc.: Staying Focused

This moldmaker’s firm belief in continuous education for its employees combined with advanced training and cutting-edge technologies increases total delivered value of its products.

While a number of mold shops start with humble beginnings, what makes each one different is how it evolves over the years. Tech Tool & Mold (Meadville, PA) is no exception. Founded in 1973 by William and Eva Hanaway as a precision tooling and heat treating shop, Tech Tool & Die started out as a small family business that slowly evolved into Tech Tool & Mold, Inc. in the late seventies as more complete plastic injection molds were being designed and built. In 1980, Tech Molded Plastics (Meadville, PA) was formed to provide full-service, short- and long-run injection molded plastics production including integrated assembly and packaging.

In 1990, the role of President was assumed by Scott Hanaway. Scott shared his parents’ love of precision machining, product innovation and community involvement. Scott’s vision and motivation soon placed the company on the cutting edge of technology and training.

Through the years, Tech has grown from occupying rental space in a small garage to a 54,000-square-foot facility containing the latest in equipment and a highly skilled workforce of approximately 92 employees. Today the organization includes two award-winning, world-class manufacturing companies—Tech Tool & Mold, Inc. and Tech Molded Plastics LP—providing full-service contract manufacturing to industries that require highly complex, precision components.

Invested in Service

Hanaway believes that continual investments in new technologies and equipment are essential to giving Tech’s customers the highest total value needed to compete in today’s global marketplace. “We have more than 33 years of experience in supplying full-service contract manufacturing for precision molded plastics,” he states. “We are known internationally for innovative technical engineering, support, customer service and the ability to convert complex ideas into viable products. Our people and their years of experience in the industry are driven to find innovative solutions that speed products to market with maximum efficiency. We continually invest in new technology, advanced training and cutting-edge techniques that increase the total delivered value of precision molded plastics. Our ability to integrate high-technology manufacturing systems with innovative practices fosters the culture needed to identify process improvement techniques.”

To that end, last year in June, 2005 Tech added a Charmilles Roboform 240cc—utilizing a specially designed programming system co-developed by Tech and the manufacturer that delivered more than a 10 percent delivery improvement with greater quality and reduced total cost. Earlier this year, the company added four Nissei all electric presses that provide increased productivity and quality of products. Hanaway notes that this investment has helped to stabilize molding parameters, improve efficiency, increase control and improve networking capabilities. “The electric press system is integrated with production monitoring and a computerized network to control and deliver the data needed to dramatically reduce process variation costs,” he adds. In February, Tech also acquired a Charmilles Roboform 35P with 90/4 electrode and pallet configuration using a QCRi Robot and ZAC technology.

On the business end, 13 members of Tech’s management team helped to develop the curriculum and began attending project management coursework through Edinboro University of PA’s manufacturing technology program with a focus on a systems approach to management. The class is being taught by Professor Peter Kushinikov through Edinboro University of Pennsylvania’s Manufacturing Engineering Technology program. Kushinikov has many years of experience as a machinist, as well as a background in plastics technology and engineering. Students successfully completing the course will receive Continuing Education Credits in addition to the project management skills that they will take back to their respective workplaces.

Talented Toolmakers

According to Hanaway, one of the company’s ongoing challenges is to find and develop workers that possess the talent needed in today’s technologically advanced manufacturing environment. “We are meeting this challenge by partnering with local trade schools, universities and associations through investments in time, resources and funding,” Hanaway explains. “Our people hold positions on several boards and advisory positions with educational institutions, chambers of commerce, industry partnerships and community foundations. We devote our time and our people to speak with local universities, trade schools, students and parental groups to make certain that a curriculum is offered that builds the skills needed to enter into a high technology industry.

“Through serving on the board and in the committee of the Northwestern PA Chapter of the National Tooling and Machining Association and the Metals Industry Partnership, we have raised the funds needed to market and campaign for education, industry awareness and recruitment,” Hanaway continues. “Vocational schools, precision manufacturing educational institutions and technical education degrees have seen significant increases in enrollment and boast exceptionally high placement rates.”

All of Tech’s employees are targeted to receive a minimum of 40 hours of training per year and the company offers training reimbursement. Business training also is available. “It is our belief that in order for our managers to be the best at making critical manufacturing decisions they must be educated to make good, sound business decisions,” Hanaway says. “We offer training in finance, communications, strategic planning, goal setting, program management and lean processes. We also try to provide additional educational resources for our people and customers on our Web site. Currently we are featuring informational white papers regarding how to leverage innovation and implement project management.”

Currently, Tech has a number of its plastics people enrolled in Plastics 101 and Processing, 13 of its off-shift toolroom employees are enrolled in Applied Communications, 16 people attend mold maintenance seminars (taught by Brian Young of Penn State Behrend in Erie, PA) and 13 staff members have just completed Project Management.

Adept Apprentices

Tech also takes care of its new hires with an apprenticeship program that has been in place for more than 30 years and graduating approximately 14 apprentices. “While the National Institute for Machining Skills (NIMS) mandates the skills that the apprentice must possess when their training is complete after 8,000 hours, we require that our apprentices move at regular and structured intervals through the training program, ensuring that each hour is adding to their skills,” Hanaway states. “The apprentices receive a substantial part of their training on computerized machines and engineering software that is updated frequently to keep pace with technology. A large portion of the apprenticeship training takes place at Precision Manufacturing Institute (PMI), which is a new multi-million dollar facility located just a couple of blocks away from us.”

Tech apprentices also receive plastics production training so that they not only know how to build and maintain a mold, but they also learn what it takes to produce an acceptable part from it. “We are closely involved with the National Tooling and Machining Association (NTMA) and our apprentices get the opportunity to compete at both a regional and national level,” Hanaway points out. “Such competitions can be a tremendous learning experience for the apprentices, as well as offering them the chance to win thousands of dollars in prizes. Our apprentices are often required to attend national trade shows and events where they are able to gain knowledge of leading technology and industry best practices.”

Reaching Goals

The goal that Tech has defined as a differentiator and a profit motivator is through the development of people, technology and innovative techniques for long-term, value-driven services, Hanaway points out. “Tech’s recipe for competitive strength is founded upon excellence training for core technological skills combined with creativity, innovation and project management. The most advanced machining centers and equipment can be purchased and located practically anywhere in the world by any competitor. The strategy and objective that we feel defines the future of manufacturing lies in the talent to develop new processes, more advanced techniques and demand-driven services. Our staff of highly trained, innovative people will drive the next generation of integrated precision tooling and molding disciplines that mold products faster, more efficient and with added value.”

In 2002, Tech helped to form a 40-member consortium of highly specialized tooling and machining companies, represented at industry-specific trade shows under the name The Source. “This gives us the ability to take on large-scale projects that require multiple disciplines and/or services that a single company may not be able to adequately provide,” Hanaway notes.

Then, the company expanded in 2003 when an additional 24,000 square feet was added with the purchase of a co-located facility.

Tech continues to actively seek growth-oriented opportunities beyond existing services and alliances—including acquisitions. Hanaway sums up his position succinctly: “We focus internally for operational excellence and externally for strength in market position.”

Related Content

Women Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

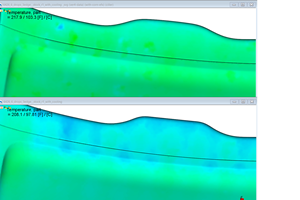

Read MoreQuickly Troubleshoot New Molding Defect with Moldfilling Software

SyBridge Technologies analyst compares original, new Moldflow process simulation results, solves molding defect without tool needing to be taken out of production.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreAdvances in P20 Steel Potentially Eliminates Need for Stress Relieving After Rough Cutting

Omega Tool Corp. compares conventional, new P20 grades side by side in production fascia tools, finds no downside.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)